Product Introduction

Types of MOPA Laser Marking Machines

-

FM-MD Laser Marking Machine

Rated 4.63 out of 5$4,160.00 – $17,030.00Price range: $4,160.00 through $17,030.00 Select options This product has multiple variants. The options may be chosen on the product page -

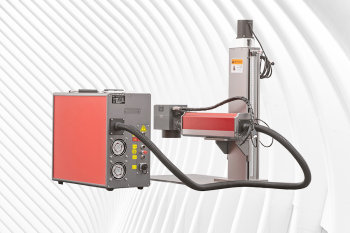

FM-MH Laser Marking Machine

Rated 4.63 out of 5$4,550.00 – $17,420.00Price range: $4,550.00 through $17,420.00 Select options This product has multiple variants. The options may be chosen on the product page -

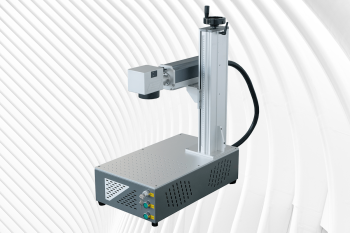

FM-MS Laser Marking Machine

Rated 4.50 out of 5$4,290.00 – $17,160.00Price range: $4,290.00 through $17,160.00 Select options This product has multiple variants. The options may be chosen on the product page -

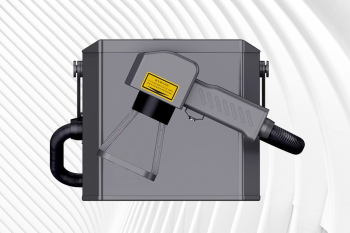

FM-MP Laser Marking Machine

Rated 4.75 out of 5$4,420.00 – $17,290.00Price range: $4,420.00 through $17,290.00 Select options This product has multiple variants. The options may be chosen on the product page -

FM-ME Laser Marking Machine

Rated 4.63 out of 5$5,460.00 – $18,330.00Price range: $5,460.00 through $18,330.00 Select options This product has multiple variants. The options may be chosen on the product page -

FM-MF Laser Marking Machine

Rated 4.63 out of 5$6,240.00 – $19,110.00Price range: $6,240.00 through $19,110.00 Select options This product has multiple variants. The options may be chosen on the product page

Application of MOPA Laser Marking Machines

Why Choose Us

Precision Engineering

Our machines deliver ultra-fine marking and engraving with high-speed galvanometer systems and stable laser sources for consistent, reliable output.

Wide Material Compatibility

We offer different laser types to match your needs, ensuring crisp, permanent marks on metal, plastic, wood, leather, and more.

User-Friendly Software

Intuitive control software allows easy setup, flexible design import, and precise marking even for first-time users.

Customizable Solutions

We provide machine options tailored to your product size, line speed, and marking content for seamless integration.

Low Maintenance

Our systems run cleanly with no inks or chemicals, lowering long-term operating costs and environmental impact.

Dedicated Support and Service

Faster Laser offers professional training, remote troubleshooting, and responsive service to keep your production running smoothly.

MOPA Laser Marking Machines VS Other Marking Machines

| Comparison Item | MOPA Laser Marking Machine | Dot Peen Marking Machine | Inkjet Printing Machine | Stamping Machine |

|---|---|---|---|---|

| Marking Method | Adjustable-pulse fiber laser beam | Mechanical pin striking | Ink sprayed through nozzle | Die pressed into material |

| Marking Precision | Very high, excellent for fine detail | Moderate | Moderate | Low to moderate |

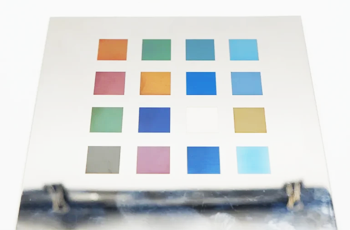

| Color Marking on Metal | Yes (stainless steel, titanium) | No | No | No |

| Black Marking on Anodized Aluminum | Excellent clarity and contrast | No | No | No |

| Surface Contact | Non-contact | Contact-based | Non-contact | Contact-based |

| Heat Sensitivity Control | Adjustable pulse for low-heat marking | Not applicable | Not applicable | Not applicable |

| Suitable Materials | Metals, plastics, anodized aluminum, coated parts | Mostly metals | Paper, plastic, some coated surfaces | Hard metals |

| Maintenance Requirements | Low (no consumables, minimal wear) | Moderate (mechanical parts wear) | High (ink, nozzles, cleaning) | High (tooling wear) |

| Operating Cost | Low (no inks or dies) | Low | High (ink, solvent, maintenance) | Moderate (die cost, setup time) |

| Marking Durability | Permanent, high contrast | Permanent | Temporary | Permanent |

| Marking Flexibility | Very high (text, graphics, codes, colors) | Limited to basic characters | High for simple text and codes | Low |

| Automation Capability | Excellent (CNC, production line integration) | Limited | Good | Limited |

| Noise Level | Very low | High | Low | High |

| Setup Time | Short (software-based control) | Moderate | Short | Long (die production/setup) |

| Environmental Impact | Very low (no chemicals or waste) | Low | High (chemical ink, VOCs) | Moderate |

Customer Testimonials

Related Resources

Laser Marking VS Screen Printing

This article explores the key differences between laser marking and screen printing, comparing their processes, advantages, disadvantages, applications, and how to choose the right method for your needs.

Frequently Asked Questions

What Is MOPA Laser Marking?

What Laser Power Options Are Available For MOPA Laser Marking Machines?

- 20W MOPA Lasers: MOPA lasers at 20W are excellent for high-contrast marking on plastics and delicate surface treatments on metals. They can produce clean, sharp marks with minimal heat impact. These systems are commonly used for fine detail work like black marking on stainless steel, serial numbers on ABS plastic, or barcodes on anodized aluminum. Best suited for electronics, medical tools, and small-scale production.

- 30W MOPA Lasers: This power level provides more speed and flexibility while maintaining precision. It allows for detailed color marking on stainless steel and deep black contrast on titanium. It can also mark more types of plastics with improved efficiency. The 30W MOPA is ideal for phone parts, nameplates, and high-end branding applications where quality is essential.

- 60W MOPA Lasers: A 60W MOPA offers deeper engraving capability and faster production speeds. It can mark harder metals, coated surfaces, and high-density plastics with better penetration. This power level is suitable for automotive, aerospace, and tooling industries where larger batches or thicker materials are marked regularly.

- 100W MOPA Lasers: High-power 100W MOPA lasers are built for industrial settings requiring consistent, fast, and deep engraving, especially for complex surfaces and repetitive tasks. They are also capable of light cutting of thin metals, making them a hybrid solution for manufacturing.

- 200W MOPA Lasers: Designed for heavy-duty operations, the 200W system is used in metal fabrication and mold manufacturing. It enables high-speed deep engraving, such as mold cavity marking or cutting coated metals. The system is robust enough for long-hour industrial tasks.

- 300W MOPA Lasers: The most powerful in the standard MOPA range, 300W lasers are used for ultra-deep engraving, thick metal branding, and large-volume marking. They are ideal for aerospace components, industrial plates, and 3D surfaces that require strong beam penetration and minimal thermal distortion.

What Is The Price Of MOPA Laser Marking Machines?

- 20W MOPA Laser Marking Machines: $4,500 – $6,500. MOPA lasers at this level are best suited for fine, high-contrast black marking on stainless steel and precise marking on plastics. These are often used in electronics, jewelry, and medical tools. They provide excellent value for businesses focused on precision rather than speed or depth.

- 30W MOPA Laser Marking Machines: $6,500 – $9,000. With more speed and flexibility than the 20W, 30W systems can mark anodized aluminum with high contrast, support limited color marking on stainless steel, and handle medium-duty production runs. Common in consumer electronics, nameplate manufacturing, and branding.

- 60W MOPA Laser Marking Machines: $9,000 – $14,000. This power level is ideal for deeper engraving, faster cycle times, and improved performance on tough plastics and coated metals. It’s commonly used in automotive parts, aerospace components, and industrial tags requiring long-lasting marks.

- 100W MOPA Laser Marking Machines: $14,000 – $18,000. High-powered MOPA systems are suited for deep engraving on hardened metals, larger batch processing, and even light cutting of thin sheets. They’re used in mold manufacturing, heavy industry, and firearm serialization, where durability and depth are essential.

- 200W-300W MOPA Laser Marking Machines: $18,000 – $25,000. These machines are built for ultra-deep engraving, complex 3D surface marking, and extremely fast throughput. They are typically found in aerospace, defense, industrial fabrication, and high-end mold production environments.

What Materials Can Be Marked With MOPA Laser Marking?

- Metals: MOPA lasers excel at marking metals with high contrast, depth, and even color, depending on the pulse settings.

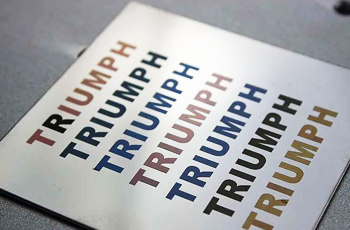

- Stainless Steel: MOPA lasers can produce black marking, white marking, and even color marking (blue, red, green, etc.) without damaging the surface.

- Aluminum (Bare and Anodized): Capable of producing bright white or high-contrast marks on anodized aluminum, which traditional fiber lasers often struggle with.

- Titanium: Enables color marking through controlled oxidation, ideal for medical and aerospace components.

- Brass and Copper: High-reflectivity metals can be marked cleanly without burning or excessive thermal input.

- Carbon Steel and Tool Steel: Suitable for serial numbers, QR codes, and deep engraving.

- Gold, Silver, and Platinum: Marked with high precision and minimal heat impact—ideal for jewelry and luxury branding.

- Plastics and Polymers: Thanks to pulse width control, MOPA lasers are far superior to standard fiber lasers when marking sensitive plastics.

- ABS (Acrylonitrile Butadiene Styrene): Clean, clear black or white marks without melting or burning.

- Polycarbonate (PC): High contrast with fine detail.

- PEEK (Polyetheretherketone): Durable marking for medical and aerospace-grade plastics.

- Nylon (PA): Crisp marks without damaging the surface structure.

- PVC: Can be marked safely at specific settings, but requires proper ventilation due to toxic fumes.

- PMMA (Acrylic): Surface marks with good contrast under the right parameters.

- Coated and Treated Materials:

- Anodized Aluminum: Bright white or deep contrasting marks without removing the oxide layer.

- Painted Metals: MOPA lasers can selectively remove coatings for clean marking without damaging the substrate.

- Powder-Coated Surfaces: Allows for barcode, text, and logo marking with high clarity.

- Laminates and Foils: Useful for marking packaging, labels, or ID tags.

- Other Materials:

- Ceramics (some types): Can be marked with surface contrast, depending on the glaze or coating.

- Printed Circuit Boards (PCBs): Allow component marking without damaging circuitry.

- Stone and Slate (limited): Can produce superficial contrast marks on certain types of stone, useful for decorative labeling.

What File Formats Are Supported By MOPA Laser Marking Machines?

- Vector Graphics: MOPA lasers rely on vector files for precise line-based markings, making them ideal for logos, text outlines, part numbers, and engineering diagrams.

- DXF (.dxf): The most common CAD-based format for laser marking; ensures precision in technical drawings.

- PLT (.plt): HPGL plotter format; widely used for simple vector logos and symbols.

- SVG (.svg): Scalable vector format suitable for web-exported icons and logos.

- AI (.ai): Adobe Illustrator files are often converted for laser use; ideal for brand marks.

- EPS (.eps): High-quality vector files used in professional design; can be imported and edited.

- Image Files (Bitmap/Raster): These formats allow MOPA lasers to engrave photos, textures, or shaded graphics.

- BMP (.bmp): The most reliable format for high-resolution grayscale engraving.

- JPG / JPEG (.jpg, .jpeg): Usable for photos, though image compression may affect clarity.

- PNG (.png): Ideal for logos and icons with transparent backgrounds.

- GIF (.gif): Acceptable for simple line art but limited in resolution.

- Text and Variable Data Files: For automated serial numbers, date stamps, and QR codes, MOPA laser software supports:

- TXT (.txt): Plain text files for static or serialized content.

- CSV (.csv): Commonly used for batch processing with variable data like product IDs or names.

- XLS / XLSX (.xls, .xlsx): Excel files allow complex data lists and multi-field entries to be imported.

- Barcode and Code Integration: MOPA systems typically support the creation and direct marking of:

- 1D Barcodes: Code 39, Code 128, EAN, etc.

- 2D Codes: QR codes, DataMatrix, PDF417—generated in-software or linked to data files.

- Software Compatibility: MOPA laser marking machines commonly use EZCAD2 or EZCAD3 software, which supports all these file types and enables:

- Layered marking

- Parameter setting (pulse width, power, frequency)

- 3D marking (if hardware allows)

What Are The Disadvantages Of MOPA Laser Marking Machines?

- Higher Cost: MOPA laser marking machines are more expensive than standard fiber laser systems. A typical MOPA machine ranges from $4,500 to $25,000, depending on power and configuration. This price increase reflects the added complexity of the laser source and its expanded control capabilities, which may be unnecessary for simple marking needs.

- More Complex Setup and Operation: Unlike fixed-pulse fiber lasers, MOPA lasers allow for adjustment of pulse width, frequency, and energy. While this offers more control, it also requires greater technical expertise. Inexperienced users may struggle to find the right parameters for different materials, which can lead to inconsistent results.

- Slower Speed for Color Marking: MOPA lasers can produce colorful markings on stainless steel and titanium, but this process is significantly slower than standard black or white marking. The machine must operate at lower speeds with multiple passes to create the desired oxidation effects, which reduces overall throughput.

- Unnecessary for Basic Metal Marking: If your marking tasks involve only basic serial numbers, barcodes, or logos on metal surfaces, a standard fiber laser can perform just as well at a lower cost. The advanced features of a MOPA laser may be overkill for simple production needs.

- Limited Material Cutting Capabilities: MOPA lasers are excellent at marking and light engraving, but they are not designed for cutting applications, especially on thicker metals or non-metals. Users needing both marking and cutting functions may require a separate laser cutting machine.

- Higher Power Models Require Better Cooling: Machines rated at 100W or above generate more heat and often need enhanced air or water cooling systems to maintain stable performance, adding to equipment cost and maintenance.

What Are The Operating Environment Requirements For MOPA Laser Marking Machines?

- Temperature and Humidity

- MOPA lasers perform best in a controlled temperature range of 15℃ to 35℃ (59°F to 95°F). Humidity should be maintained between 30% and 75% relative humidity, with no condensation.

- Sudden changes in temperature or high humidity can lead to condensation on optical components and internal electronics, which can distort the beam path or cause damage.

- Ventilation and Air Quality

- These machines must be operated in well-ventilated environments to dissipate heat and remove fumes. A fume extractor is essential when marking plastics, painted surfaces, or coated metals, which can release hazardous gases.

- Dust-free air is also important—fine dust particles can settle on laser optics or galvo mirrors, degrading precision and causing maintenance issues.

- Power Supply Requirements

- MOPA machines require a stable power supply, typically 110V or 220V AC, depending on the model. Voltage should remain within a ±10% range.

- To prevent damage from surges or instability, it’s recommended to use a surge protector or voltage regulator. For higher-wattage MOPA systems (e.g., 100W+), ensure adequate current capacity and circuit protection.

- Workspace Setup and Clearance

- The machine should be installed on a level, vibration-free surface. Allow at least 50 cm of clearance around all sides for heat dissipation and access to maintenance points.

- Avoid placing the machine near heavy machinery or sources of vibration, which can interfere with laser stability and mark alignment.

- Laser Safety Considerations

- MOPA systems typically emit 1064 nm near-infrared laser radiation, which is invisible but hazardous to eyes and skin.

- If the machine is not enclosed, always wear laser safety glasses with appropriate OD protection and operate in a Class IV laser-controlled area that has warning labels and restricted access.

- If enclosed, ensure interlocks, doors, and safety features are functional.

What Is The Service Life Of MOPA Laser Marking Machines?

- Laser Source Lifespan: MOPA laser systems use fiber laser technology, which is known for durability. A high-quality MOPA laser source (such as from JPT or IPG) typically lasts 80,000 to 100,000 hours. This is the expected operational life before significant performance degradation occurs in the laser emitter.

- System Lifespan: With regular maintenance and clean working conditions, the entire machine, including the control system, galvanometer scanner, lens, and housing, can operate reliably for 10 to 15 years. The service life depends on operating hours, duty cycle, and environmental conditions.

- Maintenance Considerations: To maximize lifespan:

- Operate within stable temperature and humidity ranges.

- Use clean power with surge protection.

- Keep optics and galvo mirrors free of dust or residue.

- Maintain proper ventilation and cooling to avoid overheating.