Product Introduction

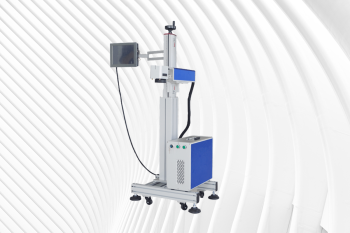

Types of Fiber Laser Marking Machines

-

FM-FD Laser Marking Machine

Rated 4.75 out of 5$2,990.00 – $26,650.00Price range: $2,990.00 through $26,650.00 Select options This product has multiple variants. The options may be chosen on the product page -

FM-FH Laser Marking Machine

Rated 4.50 out of 5$3,380.00 – $27,040.00Price range: $3,380.00 through $27,040.00 Select options This product has multiple variants. The options may be chosen on the product page -

FM-FS Laser Marking Machine

Rated 5.00 out of 5$3,120.00 – $26,780.00Price range: $3,120.00 through $26,780.00 Select options This product has multiple variants. The options may be chosen on the product page -

FM-FP Laser Marking Machine

Rated 4.75 out of 5$3,250.00 – $26,910.00Price range: $3,250.00 through $26,910.00 Select options This product has multiple variants. The options may be chosen on the product page -

FM-FE Laser Marking Machine

Rated 4.75 out of 5$4,290.00 – $27,950.00Price range: $4,290.00 through $27,950.00 Select options This product has multiple variants. The options may be chosen on the product page -

FM-FF Laser Marking Machine

Rated 4.75 out of 5$5,070.00 – $28,730.00Price range: $5,070.00 through $28,730.00 Select options This product has multiple variants. The options may be chosen on the product page

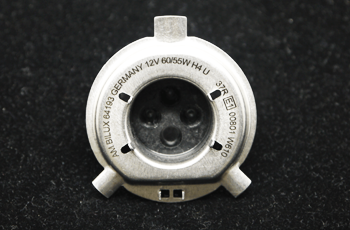

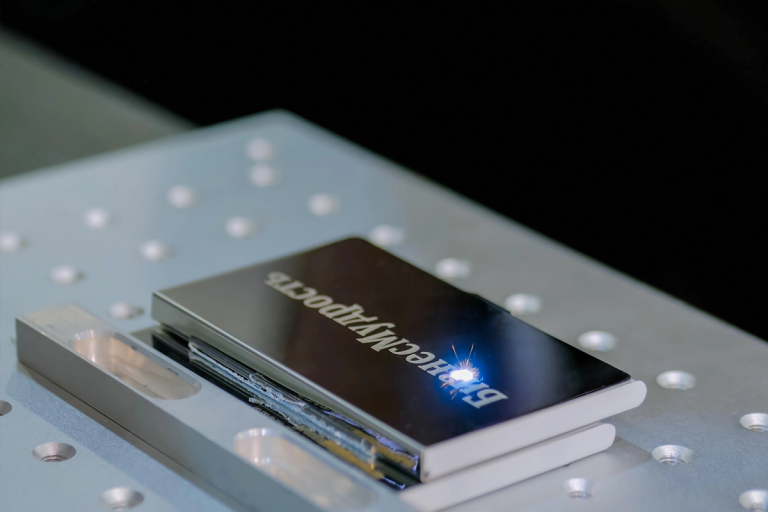

Application of Fiber Laser Marking Machines

Why Choose Us

Precision Engineering

Our machines deliver ultra-fine marking and engraving with high-speed galvanometer systems and stable laser sources for consistent, reliable output.

Wide Material Compatibility

We offer different laser types to match your needs, ensuring crisp, permanent marks on metal, plastic, wood, leather, and more.

User-Friendly Software

Intuitive control software allows easy setup, flexible design import, and precise marking even for first-time users.

Customizable Solutions

We provide machine options tailored to your product size, line speed, and marking content for seamless integration.

Low Maintenance

Our systems run cleanly with no inks or chemicals, lowering long-term operating costs and environmental impact.

Dedicated Support and Service

Faster Laser offers professional training, remote troubleshooting, and responsive service to keep your production running smoothly.

Fiber Laser Marking Machines VS Other Marking Machines

| Comparison Item | Fiber Laser Marking Machine | Dot Peen Marking Machine | Inkjet Printing Machine | Stamping Machine |

|---|---|---|---|---|

| Marking Method | Focused fiber laser beam | Mechanical pin impact | Ink droplets sprayed onto surface | Mechanical die pressed onto surface |

| Marking Speed | Very fast | Moderate | Very fast | Fast |

| Marking Precision | High (fine detail, high resolution) | Moderate | Moderate | Low to moderate |

| Surface Contact | Non-contact | Contact-based | Non-contact | Contact-based |

| Marking Durability | Permanent, wear-resistant | Permanent but shallow | Temporary, can fade | Permanent |

| Suitable Materials | Metals, some plastics, coated materials | Mostly metals | Paper, plastic, some metals | Mostly metals and hard surfaces |

| Maintenance Requirements | Low (no moving parts or consumables) | Moderate (mechanical wear) | High (ink clogging, refills) | High (die wear and alignment) |

| Operating Cost | Low (no consumables) | Low | High (consumables and maintenance) | Moderate (tooling costs) |

| Environmental Impact | Minimal (no chemicals or waste) | Low | High (ink waste, solvents, VOCs) | Moderate (no emissions, but waste metal) |

| Setup Time | Short | Moderate | Short | Long (custom dies) |

| Marking Flexibility | High (text, logos, QR, barcodes, graphics) | Limited | High | Low |

| Surface Damage Risk | Very low | Medium (surface indentation) | None | High (physical deformation) |

| Noise Level | Low | High | Low | High |

| Automation Compatibility | Excellent (CNC, production lines, robotics) | Limited | Good | Limited |

| Typical Applications | Electronics, auto parts, medical tools, tools | Nameplates, steel components, machinery | Packaging, expiration dates, retail labeling | Branding metal goods, heavy-duty parts |

Customer Testimonials

Related Resources

Laser Marking VS Screen Printing

This article explores the key differences between laser marking and screen printing, comparing their processes, advantages, disadvantages, applications, and how to choose the right method for your needs.

Frequently Asked Questions

What Is Fiber Laser Marking?

- Etching: Removes surface material for shallow, high-contrast marks.

- Engraving: Deeper removal for tactile or long-lasting marks.

- Annealing: Heats the surface to create oxidation-based marks with no material removal—ideal for stainless steel.

- Black Marking: Produces a dark, high-contrast mark on metal, especially anodized aluminum or stainless steel.

What Laser Power Options Are Available For Fiber Laser Marking Machines?

- 20W Fiber Laser Marking Machines: These entry-level systems are ideal for fine, shallow marking tasks. They work well on anodized aluminum, stainless steel, and some plastics. Best used for serial numbers, barcodes, and ID codes in small batches or light-duty operations.

- 30W Fiber Laser Marking Machines: A widely used and balanced option, 30W systems offer faster speeds and deeper marking capability than 20W. They are commonly used for nameplates, logos, tool marking, and mid-volume production on metals and plastics.

- 50W Fiber Laser Marking Machines: Suitable for deeper engraving and higher-speed processing, 50W machines are ideal for marking hard metals, including carbon steel, titanium, and brass. They are frequently used in automotive, aerospace, and heavy manufacturing applications.

- 60W Fiber Laser Marking Machines: Designed for heavy-duty industrial use, these machines provide faster throughput and are capable of deep metal engraving, mold marking, and high-contrast labeling on various alloys. They are ideal for longer production cycles and continuous operation.

- 70W Fiber Laser Marking Machines: With increased power and beam intensity, 70W systems are best for marking thick or difficult materials at high speed. Applications include batch code marking on hard alloys and fast etching on coated metal parts.

- 100W Fiber Laser Marking Machines: These high-power systems are engineered for maximum depth, marking speed, and industrial-grade performance. They are well-suited for firearm engraving, tool marking, aerospace components, and other applications requiring high precision and rugged durability.

How Much Do Fiber Laser Marking Machines Cost?

- 20W-30W Fiber Laser Marking Machines: $3,000-$6,000. These entry-level machines are best suited for small businesses or workshops. They efficiently mark metals like stainless steel, aluminum, and brass, as well as some plastics. Common applications include barcodes, logos, and serial numbers. Machines in this range usually come with open workstations and basic software like EZCAD.

- 30W-50W Fiber Laser Marking Machines: $6,000-$12,000. Mid-range machines offer faster marking speeds, deeper engraving, and broader material compatibility. They are commonly used in tool manufacturing, automotive parts, and nameplate engraving. Many models include rotary devices for cylindrical objects and enhanced cooling or lens systems.

- 50W-100W Fiber Laser Marking Machines: $12,000-$20,000. Designed for heavy-duty industrial use, these machines are capable of deep engraving and high-throughput batch marking. Ideal for aerospace, firearm, and mold industries, these systems offer higher precision, longer duty cycles, and better reliability.

- Advanced or Custom Fiber Laser Marking Machines: $20,000-$35,000. High-end systems may include 3D engraving capabilities, automated focus adjustment, and fully enclosed Class 1 safety cabinets. These are often used in medical device manufacturing, electronics, and high-volume production lines.

What Materials Can Be Marked With Fiber Lasers?

- Metals: Fiber lasers mark all types of metals with excellent speed, contrast, and durability.

- Stainless Steel: Fiber lasers mark stainless steel with high precision and can produce black, white, or color markings (with MOPA models).

- Aluminum: Excellent for anodized and bare aluminum marking, often used for nameplates and product branding.

- Brass and Copper: High-reflectivity materials like brass and copper are effectively marked with fiber lasers, though optimal settings are essential.

- Titanium: Ideal for color marking, serial numbers, and aerospace part identification.

- Carbon Steel: Frequently used for deep engraving, tool marking, and industrial parts.

- Gold and Silver: Jewelry and precious metals can be marked without damaging the material, thanks to the precise energy control.

- Other Alloys: Including nickel, zinc, chrome, and tungsten—all suitable for identification and branding.

- Plastics: Certain engineering plastics absorb fiber laser energy well and can be marked cleanly.

- ABS: Common in electronics, ABS produces high-contrast markings.

- Polycarbonate: Offers good clarity and contrast with fiber lasers.

- PEEK: Used in aerospace and medical parts; supports clear, fine markings.

- Nylon: Often used for consumer goods, labels well under fiber lasers.

- PVC (with caution): Can be marked, but is not recommended due to toxic fume generation.

- Coated and Treated Surfaces:

- Anodized Aluminum: Fiber lasers can ablate the surface layer to produce high-contrast marks.

- Painted Metals: Fiber lasers are effective at removing paint layers to reveal the base metal for clear identification.

- Plated Metals: Suitable for marking without penetrating deeply into the substrate.

- Other Industrial Materials:

- Some Ceramics: Depending on the composition, fiber lasers can produce readable marks on industrial ceramics.

- PCB Materials: Ideal for fine traceability codes and labels on printed circuit boards.

- Stone and Slate: High-power fiber lasers can mark dense, smooth stone surfaces with permanent contrast.

What File Formats Do Fiber Laser Marking Machines support?

- Vector Graphics: Fiber lasers use vector paths to produce clean, scalable, and precise outlines—ideal for text, logos, and part shapes.

- DXF (.dxf): Widely used for CAD drawings and part outlines; ideal for industrial and engineering applications.

- PLT (.plt): Commonly supported by laser software like EZCAD; suitable for logos and line art.

- AI (.ai): Adobe Illustrator files are great for detailed vector graphics.

- SVG (.svg): Scalable vector graphics; flexible and lightweight for web and graphic-based designs.

- EPS (.eps): Encapsulated PostScript files for high-resolution vector content.

- Raster / Bitmap Images: Fiber lasers also support photo engraving or texture marking using raster files, though vector files are preferred for sharpness.

- BMP (.bmp): A lossless format ideal for precise photo engraving.

- JPG/JPEG (.jpg, .jpeg): Common for photos and backgrounds; best used after optimizing for contrast.

- PNG (.png): Supports transparency; useful for isolated logos and image files.

- GIF (.gif): Limited use but acceptable for simple line-based images.

- Text and Data Files: These are used for dynamic content like serial numbers, QR codes, and batch data.

- TXT (.txt): Supports plain text and automatic serialization.

- CSV (.csv): Enables batch processing of part numbers, codes, and other variable data.

- XLS/XLSX (.xls, .xlsx): Excel files are useful for larger automated marking jobs from databases.

How Large Marking Areas Do Fiber Laser Marking Machines Support?

- 110×110 mm (4.3″ × 4.3″): This is the most common marking field. It provides the highest energy density and marking resolution, making it ideal for fine text, small parts, tool identification, and precision logos. The beam remains sharp and focused throughout the field.

- 150×150 mm (5.9″ × 5.9″): This larger field allows users to mark medium-sized workpieces or a larger group of small parts in a single pass. It offers a good balance between marking area and beam sharpness, suitable for nameplates, batch codes, and product logos.

- 175×175 mm (6.9″ × 6.9″): A flexible field used for more complex marking setups, including jigs that hold multiple items. It’s often chosen in industrial environments where flexibility and coverage are needed without compromising clarity.

- 200×200 mm (7.8″ × 7.8″): This area allows batch marking or single larger components. However, energy density begins to spread more, which may reduce depth and contrast slightly if not compensated with higher laser power.

- 300×300 mm (11.8″ × 11.8″): One of the largest standard fields supported by galvo-based fiber laser systems. Ideal for marking trays of parts or larger signage elements. Precision may be lower at the edges, and engraving depth is reduced compared to smaller areas.

What Are The Disadvantages Of Fiber Laser Marking Machines?

- Limited Material Compatibility: Fiber lasers work extremely well on metals and some engineering plastics, but are not suitable for organic or transparent materials.

- Wood and Paper: Fiber lasers cannot mark or engrave wood, paper, or cardboard effectively. These materials do not absorb the 1064 nm wavelength efficiently and may char or burn.

- Leather and Fabrics: These materials require gentler wavelengths like those from CO₂ lasers. Fiber lasers are likely to damage or burn them unevenly.

- Glass and Ceramics: Most fiber lasers cannot mark clear glass or ceramics unless the surfaces are coated or treated, making them less versatile for decorative applications.

- Transparent and Light Plastics: Materials like acrylic (PMMA), PET, or clear polycarbonate absorb little energy from fiber lasers, resulting in weak or no visible marks. UV lasers are better suited for these applications.

- Inconsistent Plastic Marking Results: Even among compatible plastics like ABS or PEEK, the quality of marks may vary based on formulation, pigment, or additives.

- Plastics can show inconsistent contrast or discoloration when marked with fiber lasers, and some may produce fumes or discolor under the laser beam.

- Restricted Marking Area: Fiber laser marking machines typically offer fixed marking fields like 110×110 mm or 300×300 mm, depending on the lens.

- For larger items or multiple-piece layouts, additional XY motion systems or rotary attachments must be added, which increase the cost and complexity of operation.

- High Upfront Cost for Advanced Models: While basic 20W or 30W machines are affordable, MOPA fiber lasers or systems with 3D dynamic focus, color marking, or enclosed safety cabinets can be significantly more expensive.

- This may not be suitable for small businesses or low-volume production needs.

- Not Designed for Cutting Applications: Fiber laser markers are optimized for engraving and marking only.

- Attempting to cut with a marking system can damage internal components like galvo mirrors and reduce system lifespan.

What Are The Operating Environment Requirements For Fiber Laser Marking Machines?

- Temperature and Humidity: Fiber lasers operate optimally in stable temperatures between 15℃ and 35℃ (59℉ to 95℉). Extreme cold or heat can affect internal components and beam quality. Relative humidity should be maintained between 30% and 75%, non-condensing, to avoid moisture buildup on optics or electronics.

- Ventilation and Airflow: Proper ventilation is crucial to avoid the accumulation of heat and fumes.

- Fiber lasers generate minimal waste, but fume extractors are still necessary, especially when marking coated metals or plastics that can emit toxic gases.

- Air-cooled systems need unrestricted airflow; do not place them in enclosed cabinets unless designed for it.

- Clean and Dust-Free Workspace: Dust and debris in the air can settle on laser optics and scanning mirrors, degrading marking quality.

- Install in a cleanroom-like environment or use protective housings with HEPA filters if necessary.

- Avoid operating near grinding, cutting, or polishing equipment that generates particulates.

- Power Supply Stability: Fiber lasers typically require 110V or 220V AC, depending on model and region.

- Voltage fluctuations beyond ±10% can damage sensitive electronics.

- Use voltage stabilizers or uninterruptible power supplies (UPS) to protect the machine from spikes and power loss.

- Positioning and Mounting: Place the fiber laser on a flat, stable surface to prevent vibrations that can misalign the marking head or distort accuracy.

- Ensure adequate clearance (at least 50 cm) on all sides for airflow and maintenance.

- Avoid placing the machine near strong magnetic fields or electronic noise sources, which can interfere with control systems.

- Safety and Access Control: Fiber lasers are typically Class IV devices unless enclosed.

- Use laser safety glasses rated for 1064 nm wavelength.

- If open-frame, install in a designated laser safety zone with appropriate warning labels and restricted access.

- For Class I enclosed models, ensure safety interlocks and shielding are intact.