Product Introduction

Types of Laser Marking Machines

-

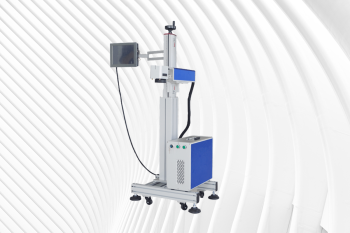

FM-FD Laser Marking Machine

Rated 4.75 out of 5$2,990.00 – $26,650.00Price range: $2,990.00 through $26,650.00 Select options This product has multiple variants. The options may be chosen on the product page -

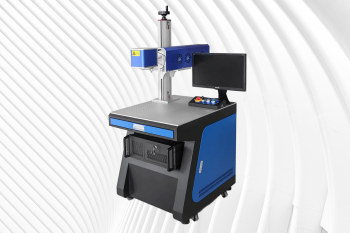

FM-FH Laser Marking Machine

Rated 4.50 out of 5$3,380.00 – $27,040.00Price range: $3,380.00 through $27,040.00 Select options This product has multiple variants. The options may be chosen on the product page -

FM-FS Laser Marking Machine

Rated 5.00 out of 5$3,120.00 – $26,780.00Price range: $3,120.00 through $26,780.00 Select options This product has multiple variants. The options may be chosen on the product page -

FM-FP Laser Marking Machine

Rated 4.75 out of 5$3,250.00 – $26,910.00Price range: $3,250.00 through $26,910.00 Select options This product has multiple variants. The options may be chosen on the product page -

FM-FE Laser Marking Machine

Rated 4.75 out of 5$4,290.00 – $27,950.00Price range: $4,290.00 through $27,950.00 Select options This product has multiple variants. The options may be chosen on the product page -

FM-FF Laser Marking Machine

Rated 4.75 out of 5$5,070.00 – $28,730.00Price range: $5,070.00 through $28,730.00 Select options This product has multiple variants. The options may be chosen on the product page -

FM-CD Laser Marking Machine

Rated 4.75 out of 5$4,290.00 – $23,920.00Price range: $4,290.00 through $23,920.00 Select options This product has multiple variants. The options may be chosen on the product page -

FM-CH Laser Marking Machine

Rated 4.63 out of 5$4,680.00 – $24,310.00Price range: $4,680.00 through $24,310.00 Select options This product has multiple variants. The options may be chosen on the product page

Application of Laser Marking Machines

Why Choose Us

Precision Engineering

Our machines deliver ultra-fine marking and engraving with high-speed galvanometer systems and stable laser sources for consistent, reliable output.

Wide Material Compatibility

We offer different laser types to match your needs, ensuring crisp, permanent marks on metal, plastic, wood, leather, and more.

User-Friendly Software

Intuitive control software allows easy setup, flexible design import, and precise marking even for first-time users.

Customizable Solutions

We provide machine options tailored to your product size, line speed, and marking content for seamless integration.

Low Maintenance

Our systems run cleanly with no inks or chemicals, lowering long-term operating costs and environmental impact.

Dedicated Support and Service

Faster Laser offers professional training, remote troubleshooting, and responsive service to keep your production running smoothly.

Laser Marking Machines VS Other Marking Machines

| Comparison Item | Laser Marking Machine | Dot Peen Marking Machine | Inkjet Printing Machine | Stamping Machine |

|---|---|---|---|---|

| Marking Method | Focused laser beam | Mechanical pin striking | Ink droplets sprayed onto surface | Mechanical force using a die |

| Marking Speed | Fast | Moderate | Very fast | Fast |

| Marking Precision | Very high | Moderate | Moderate | Low to moderate |

| Surface Damage Risk | None (non-contact) | High (physical impact) | None | High (indentation) |

| Marking Durability | Permanent, high resistance | Permanent but shallow | Temporary, can fade | Permanent |

| Material Compatibility | Metals, plastics, ceramics, glass, leather | Mostly metals | Paper, plastic, some metals | Mostly metals and hard materials |

| Maintenance Requirements | Low | Moderate | High (ink refills, nozzle cleaning) | High (die wear and replacement) |

| Operating Cost | Low (no consumables) | Low | High (inks, solvents) | Moderate (tooling costs) |

| Environmental Impact | Minimal, no chemicals | Low | High (chemical inks, VOCs) | Moderate |

| Noise Level | Low | High (mechanical noise) | Low | High |

| Software Integration | Excellent, supports automation and databases | Limited | Good | Very limited |

| Marking Flexibility | High (fonts, graphics, serials, QR codes) | Low to moderate | High | Low |

| Setup Time | Short | Moderate | Short | Long (custom dies needed) |

| Consumables Required | None | No | Yes (ink, solvents) | Yes (dies) |

| Typical Applications | Automotive, electronics, medical, tools, packaging | Steel parts, nameplates, VINs | Packaging, date codes, labels | Coining, branding, heavy metal part marking |

Customer Testimonials

Related Resources

Laser Marking VS Screen Printing

This article explores the key differences between laser marking and screen printing, comparing their processes, advantages, disadvantages, applications, and how to choose the right method for your needs.

Frequently Asked Questions

What is Laser Marking?

- Annealing: Heats the surface to create oxidation-based color changes, mainly used on metals like stainless steel without removing material.

- Etching: Uses a laser to slightly melt and expand the material, creating shallow, high-contrast marks.

- Carbonization: Removes non-carbon elements from the surface, leaving darkened marks, often on plastics and organic materials.

- Foaming: Melts the surface to form gas bubbles, producing raised light-colored marks, usually on plastics.

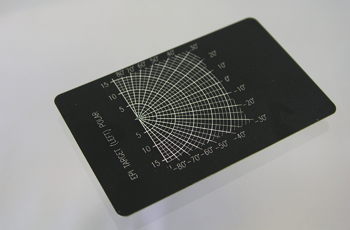

- Color Marking: Produces different hues on metals like titanium or stainless steel using precise heat control.

- Surface Coating Removal: Strips away a surface layer (like paint or anodizing) to reveal a contrasting substrate.

How Do I Determine Which Laser Marking Machines Are Right For My Material?

- Metals: Fiber lasers are highly effective at marking metals such as stainless steel, aluminum, copper, brass, titanium, and nickel alloys. They produce deep engravings, high-contrast annealing, and permanent etching. MOPA fiber lasers can even create color marks on stainless steel and black marks on anodized aluminum.

- Plastics: UV lasers and MOPA fiber lasers are best suited for marking plastics like ABS, polycarbonate, polyethylene, and PVC (with caution). UV lasers use a “cold marking” process that minimizes heat damage, making them ideal for delicate or soft plastics.

- Glass and Ceramics: UV lasers and green lasers are typically used to mark glass and ceramics. These wavelengths allow precise, crack-free engraving for decorative or industrial purposes, especially on coated or tempered surfaces.

- Organic Materials (Wood, Leather, Paper): CO2 lasers are ideal for marking and engraving organic materials. They create dark, high-contrast marks on wood and leather, and can engrave intricate designs on paper and cardboard without contact or ink.

- Rubber: CO2 lasers can mark laser-safe rubber to produce gaskets, seals, and stamps. However, rubbers with chlorine content should be avoided as they emit toxic gases during marking.

- Painted or Coated Surfaces: Fiber lasers can strip coatings to expose the underlying metal, while UV lasers are used for delicate coatings. This is useful for serial number marking, logo creation, or patterning.

What Laser Power Options Are Available For Laser Marking Machines?

- Fiber Laser Marking Machines: Fiber lasers mark metals with high speed, precision, and durability. Available in 20W, 30W, 50W, 60W, 70W, and 100W, these machines are ideal for marking stainless steel, aluminum, brass, titanium, and other metals. Lower powers like 20W and 30W suit light engraving and small-scale tasks, while 50W-100W is better for deep engraving, high-speed production, and large marking areas.

- CO2 Laser Marking Machines: Designed for organic and non-metallic materials, CO2 lasers are available in 30W, 60W, 100W, and 150W. These machines are commonly used to mark wood, acrylic, leather, paper, rubber, and coated ceramics. Higher powers like 100W and 150W offer deeper penetration and faster marking on thicker or denser materials, while 30W-60W is sufficient for light engraving and fine detailing.

- MOPA Laser Marking Machines: MOPA fiber lasers provide adjustable pulse widths, enabling versatile marking effects such as black marking on anodized aluminum or color marking on stainless steel. Available in 20W, 30W, 60W, 100W, 200W, and 300W, MOPA lasers can handle both metals and certain plastics. 20W-60W models are commonly used for precision marking, while 100W and above models are ideal for high-speed production and advanced marking applications.

- UV Laser Marking Machines: Operating at short wavelengths, UV lasers are suited for delicate and heat-sensitive materials. Power options include 3W, 5W, 10W, 12W, and 15W, making them perfect for marking plastics, glass, silicon, circuit boards, and medical devices. While 3W-5W units are used for ultra-fine marking, 10W and above provide faster speeds and improved clarity on more complex surfaces.

How Is The Cooling Of Laser Marking Machines Performed?

- Air Cooling: Many low- to mid-power laser marking machines, especially fiber and UV models up to 50W, use air cooling. These systems rely on built-in fans and heat sinks to dissipate heat from the laser source and electronics. They are simple, compact, and maintenance-friendly. However, their cooling capacity is limited, making them unsuitable for high-power or continuous-duty applications.

- Water Cooling: For high-power systems such as 60W-300W MOPA fiber lasers, 100W+ CO2 lasers, or 10W+ UV lasers, water cooling is the preferred solution. A closed-loop water chiller circulates coolant through the laser source, efficiently removing heat and maintaining a stable operating temperature. This system allows for prolonged, high-performance operation and is essential in industrial environments where laser uptime and thermal consistency are critical.

Do I Need Laser Safety Glasses To Operate Laser Marking Machines?

- Fiber Lasers (1064 nm): Fiber lasers mark metals with high-energy infrared beams that are invisible to the human eye. Even brief exposure to the direct beam or a reflection from metal surfaces can cause permanent retinal damage. Laser safety glasses rated for 1064 nm with an appropriate Optical Density (OD) are required when operating open-frame fiber laser marking machines or during maintenance and alignment.

- CO2 Lasers (10.6 µm): CO2 lasers emit far-infrared radiation that can damage the cornea and lens of the eye. While most CO2 laser marking systems are enclosed for safety, protective eyewear rated for 10.6 µm is still necessary if the system is open, lacks shielding, or is undergoing service.

- UV Lasers (355 nm): Ultraviolet lasers can cause photochemical damage to both the cornea and retina. Because UV light is invisible and potentially more harmful due to short-wavelength energy absorption, laser safety glasses that block UV wavelengths are essential for safe operation.

- Green Lasers (532 nm): Visible green laser beams can cause flash blindness and severe eye injury if viewed directly. Although the wavelength is visible, safety glasses specific to 532 nm are mandatory for exposed-beam operations.

- Enclosed Systems: For fully enclosed laser marking machines rated as Class 1 systems, where no laser radiation escapes during operation, safety glasses may not be required during normal use. However, they are still mandatory when the enclosure is open for maintenance or troubleshooting.

What File Formats Does The Laser Marking Machines Support?

- Vector Files: Laser marking machines often use vector paths for precise outlines, logos, and barcodes. Supported vector file formats typically include DXF, PLT, AI, SVG, and EPS. These formats are ideal for scaling without losing quality, and are widely used in engineering, product branding, and label design.

- Raster/Bitmap Files: For photo engraving or grayscale artwork, common raster image formats such as BMP, JPG, PNG, and GIF are supported. These are best for laser-engraved portraits, textured surfaces, or detailed branding marks, but may require image processing for optimal clarity.

- Text and Data Files: For automated serial numbers, barcodes, and variable data, formats like TXT, CSV, and Excel (XLS/XLSX) are commonly used. These allow the software to import text strings, batch data, or sequences for industrial identification and traceability.

- CAD and Technical Files: In manufacturing and engineering contexts, laser marking machines may also support DWG, STEP, and IGES files. These are useful when marking precise technical outlines or mechanical parts.

Is The Laser Marking Resistant To Solvents And Abrasion?

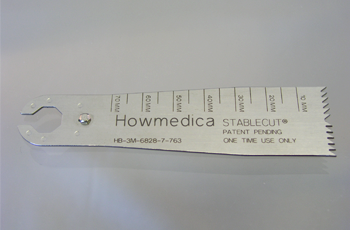

- Solvent Resistance: Laser marking changes the surface of the material itself—by engraving, annealing, foaming, or carbonizing—rather than applying an external ink or coating. Because of this, the resulting marks are highly resistant to alcohol, acetone, oils, and most industrial cleaning agents. On metals and many plastics, laser marks do not fade or dissolve even after repeated exposure to solvents, making them ideal for medical instruments, aerospace parts, and food processing equipment where regular sterilization is required.

- Abrasion Resistance: Laser marking produces permanent identification by modifying or removing material, which means the mark is embedded into the surface. This process ensures high durability even when the part is subjected to mechanical wear, vibration, or frequent handling. Marks created by fiber lasers on stainless steel or aluminum, for example, can endure scraping, scratching, and abrasion without losing readability or contrast.

Does Laser Marking Produce Fumes?

- Plastics: Many plastics—including ABS, polycarbonate, acrylic, and polyethylene—release visible fumes and potentially harmful gases when laser marked. These fumes may contain volatile organic compounds (VOCs), and in some cases (such as with PVC), toxic substances like chlorine gas. PVC should never be marked unless proper exhaust and filtration systems are in place and the material is verified as laser-safe.

- Painted and Coated Surfaces: When marking coated metals or painted surfaces, the laser burns off the top layer, producing smoke and chemical fumes that can include solvents, pigments, and heavy metals. These emissions require active fume extraction to protect both operators and equipment.

- Rubber and Synthetic Materials: Laser-safe rubbers may be marked with minimal risk, but many rubber products—especially those containing chlorine or sulfur compounds—emit strong odors and hazardous gases when ablated by a laser. Always verify the composition before marking.

- Organics (Wood, Leather, Paper): Natural materials emit smoke, soot, and particulate matter during marking. While not always toxic, these fumes can irritate the respiratory system and cloud the laser optics. Air assist and fume extraction are recommended for clean operation.

- Metals (Minimal Fumes): Bare metals like stainless steel and aluminum typically do not emit significant fumes when laser marked through annealing or etching. However, coated or anodized metals may release particles or vapors, especially if the coating is burned away.