FW-A Laser Welding Machine

The FW-A laser welding machine features a compact, movable design, handheld welding head, fiber laser, and air cooling for precise, efficient welding in various environments.

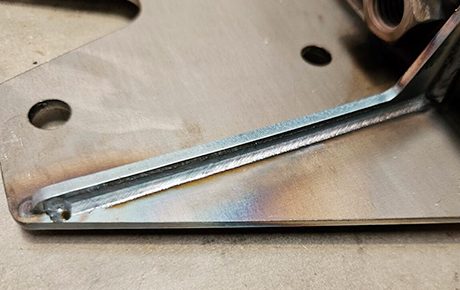

Produces clean, narrow weld seams with minimal distortion, ideal for tight-tolerance applications in many industries.

Achieves strong welds even on thick materials while minimizing heat-affected zones and reducing the risk of warping or cracking.

Operates at high speeds with consistent quality, significantly boosting production efficiency and reducing cycle times in manufacturing.

Generates smooth, clean welds with little to no spatter, reducing the need for grinding, polishing, or rework.

Capable of welding a wide range of metals, including stainless steel, aluminum, with strong joints and excellent structural integrity.

Easily integrates into automated lines, enabling seamless, high-precision welding in advanced manufacturing environments.

Laser welding does not always require filler material, but it depends on the type of joint, material thickness, and application requirements. Unlike traditional welding methods, laser welding can achieve high-strength, precise welds through autogenous (fusion) welding, where the base metals melt and fuse without additional material. However, in certain cases, filler material may be necessary.

Laser welding can be performed with or without filler material, depending on the joint design, material properties, and welding application. For tight-fit, precision welding, no filler is required, while gapped joints, dissimilar metals, or thick materials may benefit from filler material to enhance weld quality and strength.

Thermal deformation is a potential concern in laser welding, but it is significantly lower compared to traditional welding methods such as MIG, TIG, or arc welding. This is because laser welding has a highly focused heat input, leading to minimal thermal distortion. However, factors such as material type, heat buildup, welding speed, and joint design can still influence the level of deformation.

While laser welding significantly reduces thermal deformation compared to conventional welding, thin materials, excessive heat input, and poor fixturing can still cause some warping. By optimizing parameters, using proper clamping, pulsed welding, and cooling techniques, deformation can be minimized, ensuring high-quality, precise welds with minimal distortion.

Laser welding is highly versatile and can be used to create various joint types, depending on material thickness, application requirements, and weld strength needs. Below are the most common types of joints that can be welded using laser technology.

Laser welding supports butt, lap, T-joint, corner, edge, and flange joints, making it ideal for precision fabrication, structural applications, and high-strength welding. Choosing the right joint type depends on material thickness, strength requirements, and welding technique.

We offer a comprehensive warranty policy to ensure reliable performance and long-term support for our laser welding machines. Below is a detailed breakdown of our warranty coverage, including the warranty period, terms and conditions for different components, and how customers can apply for warranty service.

Our laser welding machine has a 3-year warranty on the entire machine, a 2-year warranty on the laser generator, and a 1-year warranty on core components. This structured warranty ensures that customers receive high-quality support and service. To maintain the performance of the machine and extend its life, we recommend regular maintenance and correct operation. If any problems arise, our technical support team can assist with troubleshooting and warranty claims.

Our laser welding machines meet international quality, safety, and regulatory standards, ensuring reliability, compliance, and customer confidence. Below is a detailed overview of the key certifications our machines hold and their significance.

Our laser welding machines are certified to meet international quality and safety standards, including ISO 9001, CE, and FDA certifications. These certifications ensure that our machines are manufactured with strict quality control, meet European safety regulations, and comply with U.S. laser safety requirements. Customers can be assured of high performance, reliability, and legal compliance when purchasing and operating our machines.

On-site technical support is available for laser welding machines, providing customers with hands-on assistance for installation, troubleshooting, training, and maintenance. However, this service comes at an additional cost. The standard service fee is US$200 per day, and customers are also responsible for covering the engineer’s round-trip airfare, board, lodging, and local transportation if required. This ensures that customers receive expert guidance directly at their facility to maximize machine performance and minimize downtime. The process for requesting on-site support involves contacting customer service, providing details of the issue, receiving a cost estimate, and scheduling an engineer visit. While on-site service is a valuable option, customers can also choose remote support, which includes troubleshooting via phone, email, or video calls, as well as access to online training materials and documentation at no additional cost. If in-person assistance is necessary, we are ready to arrange a visit to ensure the machine operates efficiently and reliably.

Our machines are built with robust components and high-precision engineering to ensure long-term durability and consistent welding performance in demanding environments.

We offer intelligent control systems, auto-focus laser heads, and real-time monitoring to deliver fast, accurate, and stable welding results.

Our machines support a wide range of welding methods and materials, from thin sheets to complex assemblies, across multiple industries.

We provide machine configurations tailored to your specific workflow, product design, and production volume for optimal performance and efficiency.

Faster Laser offers professional training, technical support, and fast-response service to ensure seamless operation and minimal downtime.

Our machines combine high-quality performance with competitive pricing, helping businesses maximize productivity while minimizing energy, labor, and material waste.

8 reviews for FW-A Laser Welding Machine

Natalie –

Seam repeatability means we confidently quote shorter lead times. Rework tickets dropped close to zero, freeing our inspection crew for other tasks. Gas flow meters show a thirty-percent reduction, and that alone offsets loan payments. Operators enjoy the lighter torch hose that never kinks on cold mornings.

Ella –

Hull repairs need speed and penetration on the thick plate. Dual-pulse setting achieves root fusion fast, and we cap in the same pass. Water cooler filter swaps take seconds, a blessing when the clock is ticking at dry-dock rates. Crew morale is higher because exposure time is lower.

Mason –

Aluminum art pieces used to warp while I chased seams. Pulse mode distributes energy so evenly that finished panels stay perfectly flat. Glove fatigue has vanished because the weld time per panel is half. Patrons love the flawless surface, and I love skipping the messy sanding booth.

Zoe –

My workshop builds custom bike frames to order. This machine produces strong, bright fillets on chromoly tubes without grinding. Frame alignment headaches are gone because heat pull is minimal. Online training modules were free, and remote support answered my only question in minutes. Best equipment decision this year.

Leo –

Installation took less time than unpacking our old TIG chiller. The existing 240-volt service was fine, and the footprint freed room for another press brake. Noise dropped dramatically; operators can now hear safety calls across the bay. Monthly scrap has fallen below one percent for the first time.

Owen –

We weld copper bus bars inside tight switchgear cabinets. The torch’s slim neck reaches terminals no other tool could hit. The beam interlock shuts off instantly if the nozzle moves off metal, which keeps live panels safe during field service. Customers notice the tidy workmanship right away.

Jack –

Aerospace joints demand tight specs. This machine’s consistent beam diameter keeps penetration within ±0.05 mm across long stringers. Parameter logs integrate directly with our statistical process-control software. Documentation approval is almost automatic now, and that saves days every quarter during customer audits.

Maya –

I craft brass sculptures and need micro-control on irregular joints. The foot-pedal response is instant, so feathering into tight corners feels natural. Weld beads come out so smooth that my burnishing wheels gather dust. The compact cabinet fits under my mezzanine stair without blocking floor space.