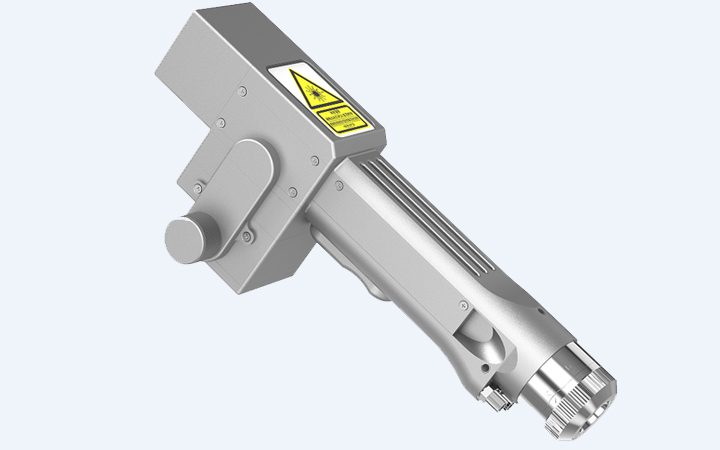

FQP Laser Cleaning Machine

The FQP laser cleaning machine features a pulsed laser, double wobble head, and mobile design for precise, safe, and efficient cleaning across industrial and delicate surfaces.

Removes rust and paint without touching the surface, preserving material integrity and preventing abrasion or deformation.

Uses no chemicals, generates minimal waste, and supports sustainable cleaning practices with reduced environmental impact.

Targets only unwanted layers with pinpoint accuracy, leaving the base material untouched—even on delicate or complex surfaces.

Features a sealed design and few moving parts, lowering maintenance time, cost, and machine downtime.

Provides rapid productivity and reduces labor costs for industrial-scale rust removal, coating stripping, and surface preparation.

Equipped with intuitive controls and safety features, making it easy to operate while protecting users from laser exposure.

Yes, the laser cleaning machine allows for the customization of cleaning parameters to meet different material and application needs. Users can adjust several key settings to optimize performance, including laser power, pulse frequency, scanning speed, beam width, and focal length. Customizable cleaning parameters:

Customizing these parameters ensures optimal cleaning results for different applications, including rust removal, paint stripping, surface preparation, and delicate cleaning of sensitive materials.

Yes, wearing laser safety goggles is essential when operating laser cleaning machines to protect your eyes from harmful laser radiation. Laser cleaning systems, especially high-power fiber lasers, emit intense laser beams that can cause serious eye damage, including retinal burns or permanent vision loss if exposed directly or indirectly through reflections.

Laser safety goggles are mandatory when using laser cleaning machines. Operators should also implement additional safety measures, such as protective enclosures, controlled workspaces, and warning signs, to prevent accidental exposure.

Yes, laser cleaning can produce harmful fumes, depending on the type of material being cleaned and the contaminants present. When a laser beam removes rust, paint, oil, or coatings, it vaporizes the surface material, generating fumes, smoke, and particulate matter that may contain toxic or hazardous substances.

Laser cleaning does produce fumes, and the level of hazard depends on the material being cleaned. Implementing fume extraction, ventilation, and protective equipment is essential to ensure operator safety and maintain a clean working environment.

We offer a comprehensive warranty policy to ensure reliable performance and long-term support for our laser cleaning machines. Below is a detailed breakdown of our warranty coverage, including the warranty period, terms and conditions for different components, and how customers can apply for warranty service.

Our laser cleaning machine has a 3-year warranty on the entire machine, a 2-year warranty on the laser generator, and a 1-year warranty on core components. This structured warranty ensures that customers receive high-quality support and service. To maintain the performance of the machine and extend its life, we recommend regular maintenance and correct operation. If any problems arise, our technical support team can assist with troubleshooting and warranty claims.

Our laser cleaning machines meet international quality, safety, and regulatory standards, ensuring reliability, compliance, and customer confidence. Below is a detailed overview of the key certifications our machines hold and their significance.

Our laser cleaning machines are certified to meet international quality and safety standards, including ISO 9001, CE, and FDA certifications. These certifications ensure that our machines are manufactured with strict quality control, meet European safety regulations, and comply with U.S. laser safety requirements. Customers can be assured of high performance, reliability, and legal compliance when purchasing and operating our machines.

On-site technical support is available for laser cleaning machines, providing customers with hands-on assistance for installation, troubleshooting, training, and maintenance. However, this service comes at an additional cost. The standard service fee is US$200 per day, and customers are also responsible for covering the engineer’s round-trip airfare, board, lodging, and local transportation if required. This ensures that customers receive expert guidance directly at their facility to maximize machine performance and minimize downtime. The process for requesting on-site support involves contacting customer service, providing details of the issue, receiving a cost estimate, and scheduling an engineer visit. While on-site service is a valuable option, customers can also choose remote support, which includes troubleshooting via phone, email, or video calls, as well as access to online training materials and documentation at no additional cost. If in-person assistance is necessary, we are ready to arrange a visit to ensure the machine operates efficiently and reliably.

Our laser cleaning machines are built with premium components and tested to perform in tough industrial environments with minimal downtime.

We offer a dry, chemical-free cleaning solution that reduces environmental impact and eliminates the need for hazardous waste disposal.

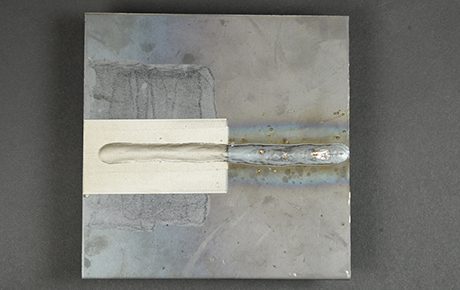

High-precision laser control delivers uniform cleaning without damaging the underlying material, even on delicate or complex surfaces.

Our systems clean rust, paint, oil, and oxidation on metal, stone, wood, and other materials across multiple industries.

With plug-and-play functionality, ergonomic handheld designs, and optional automation, our machines fit seamlessly into any workflow.

Faster Laser provides training, technical guidance, and after-sales service to ensure smooth operation and long-term value.

8 reviews for FQP Laser Cleaning Machine

Logan –

Jewelry casting trees come out with investment traces that dull the polish. The desktop laser cleaner flashes residue away, saving delicate pieces from acid etch. Apprentices learn settings quickly through clear icon menus. Customer stones never risk chemical exposure, and turnaround time on custom rings dropped dramatically during the holiday season orders.

Rylan –

Prep crews once sandblasted steel tanks before epoxy coating, filling the booth with clouds. Laser cleaning now exposes bright metal without grit. The lamp-style guide light helps trace weld seams accurately. Respirator filter changes dropped sharply, and paint adhesion pull-test scores were higher, winning praise from our largest petrochemical client.

Kayla –

Dentists requested rust-free surgical forceps refurbishment. Low-power laser mode cleans instruments gently, maintaining a mirror finish without abrasive wheels. Sterilization indicators show improved performance, and we reduced chemical passivation tanks. Staff enjoy quieter operations, and clinic directors highlight the eco-friendly service in marketing brochures, attracting additional healthcare clients rapidly near hospitals.

Natalie –

Road-salt corrosion crippled snowplow frames mid-season. The portable laser cleaner removes rust and old paint right in the garage, eliminating messy blasting media. Operators appreciate the roomy trigger grip and auto-focus. Repair turnaround shrank from three days to one, keeping more trucks on winter routes and lowering rental costs.

Sawyer –

Circuit breaker contacts need oxide removal without damaging silver tips. The pulsed laser lowers power automatically once shiny metal appears, avoiding overcleaning. Resistance measurements improved, and overheating incidents disappeared this summer. Field crews like the battery pack option, allowing rooftop work without long extension cords across active substations completely now.

Aaliyah –

Chromoly frames carried mill scale that dulled brazed joints. Quick laser passes reveal clean tubing while leaving geometry untouched. Bystanders talk easily over the quiet hum, creating a calmer workshop. My sanding station sits idle, and customers notice the sharper powder-coat finish during Saturday showroom pickups.

Jasper –

Oil refineries battle char on stainless flanges. The laser cleaner operates in gas zones using remote interlock, reducing hot-work certificates. Cleanup takes minutes, and gasket seating surfaces stay smooth. Leak tests pass first try, saving costly nitrogen cycles. Maintenance planners project significant overtime savings across the turnaround calendar next year.

Hailey –

Contractors rehabbing concrete forms once spent hours removing cured cement. Laser cleaning breaks bond lines quickly, and the water-cooled nozzle prevents thermal shock. From life extended, reducing capital purchases. Jobsite dust levels dropped well below the threshold, pleasing safety officers. Productivity gains reflect directly on our profit margins during bids lately.