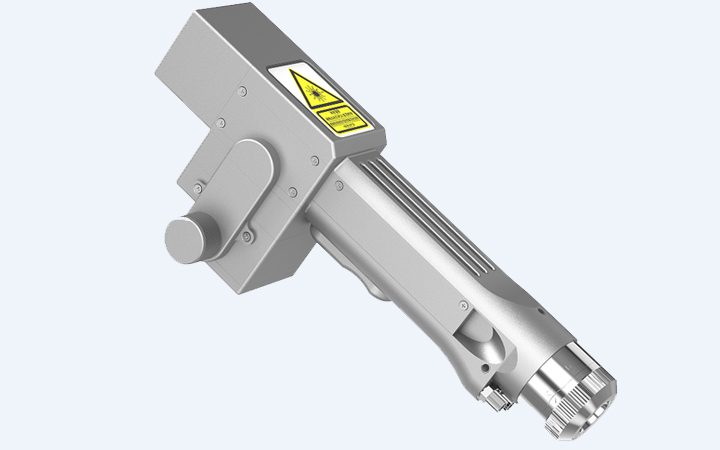

FQP-L Laser Cleaning Machine

The FQP-L laser cleaning machine features a compact luggage design, pulsed laser, and wobble head for safe, portable, and precise surface cleaning in various applications.

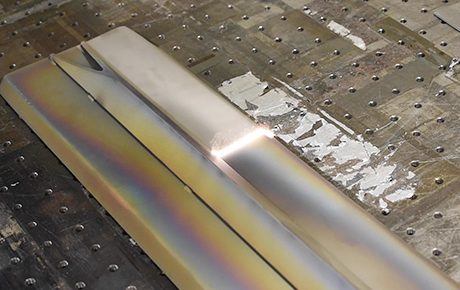

Removes rust and paint without touching the surface, preserving material integrity and preventing abrasion or deformation.

Uses no chemicals, generates minimal waste, and supports sustainable cleaning practices with reduced environmental impact.

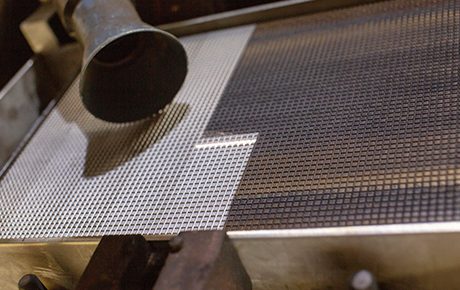

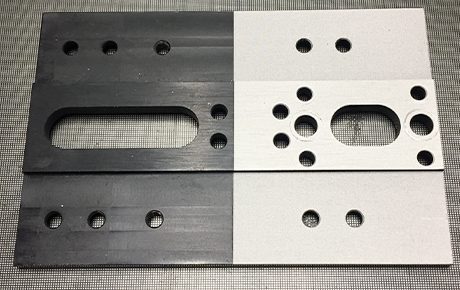

Targets only unwanted layers with pinpoint accuracy, leaving the base material untouched—even on delicate or complex surfaces.

Features a sealed design and few moving parts, lowering maintenance time, cost, and machine downtime.

Provides rapid productivity and reduces labor costs for industrial-scale rust removal, coating stripping, and surface preparation.

Equipped with intuitive controls and safety features, making it easy to operate while protecting users from laser exposure.

Yes, the laser cleaning machine allows for the customization of cleaning parameters to meet different material and application needs. Users can adjust several key settings to optimize performance, including laser power, pulse frequency, scanning speed, beam width, and focal length. Customizable cleaning parameters:

Customizing these parameters ensures optimal cleaning results for different applications, including rust removal, paint stripping, surface preparation, and delicate cleaning of sensitive materials.

Yes, wearing laser safety goggles is essential when operating laser cleaning machines to protect your eyes from harmful laser radiation. Laser cleaning systems, especially high-power fiber lasers, emit intense laser beams that can cause serious eye damage, including retinal burns or permanent vision loss if exposed directly or indirectly through reflections.

Laser safety goggles are mandatory when using laser cleaning machines. Operators should also implement additional safety measures, such as protective enclosures, controlled workspaces, and warning signs, to prevent accidental exposure.

Yes, laser cleaning can produce harmful fumes, depending on the type of material being cleaned and the contaminants present. When a laser beam removes rust, paint, oil, or coatings, it vaporizes the surface material, generating fumes, smoke, and particulate matter that may contain toxic or hazardous substances.

Laser cleaning does produce fumes, and the level of hazard depends on the material being cleaned. Implementing fume extraction, ventilation, and protective equipment is essential to ensure operator safety and maintain a clean working environment.

We offer a comprehensive warranty policy to ensure reliable performance and long-term support for our laser cleaning machines. Below is a detailed breakdown of our warranty coverage, including the warranty period, terms and conditions for different components, and how customers can apply for warranty service.

Our laser cleaning machine has a 3-year warranty on the entire machine, a 2-year warranty on the laser generator, and a 1-year warranty on core components. This structured warranty ensures that customers receive high-quality support and service. To maintain the performance of the machine and extend its life, we recommend regular maintenance and correct operation. If any problems arise, our technical support team can assist with troubleshooting and warranty claims.

Our laser cleaning machines meet international quality, safety, and regulatory standards, ensuring reliability, compliance, and customer confidence. Below is a detailed overview of the key certifications our machines hold and their significance.

Our laser cleaning machines are certified to meet international quality and safety standards, including ISO 9001, CE, and FDA certifications. These certifications ensure that our machines are manufactured with strict quality control, meet European safety regulations, and comply with U.S. laser safety requirements. Customers can be assured of high performance, reliability, and legal compliance when purchasing and operating our machines.

On-site technical support is available for laser cleaning machines, providing customers with hands-on assistance for installation, troubleshooting, training, and maintenance. However, this service comes at an additional cost. The standard service fee is US$200 per day, and customers are also responsible for covering the engineer’s round-trip airfare, board, lodging, and local transportation if required. This ensures that customers receive expert guidance directly at their facility to maximize machine performance and minimize downtime. The process for requesting on-site support involves contacting customer service, providing details of the issue, receiving a cost estimate, and scheduling an engineer visit. While on-site service is a valuable option, customers can also choose remote support, which includes troubleshooting via phone, email, or video calls, as well as access to online training materials and documentation at no additional cost. If in-person assistance is necessary, we are ready to arrange a visit to ensure the machine operates efficiently and reliably.

Our laser cleaning machines are built with premium components and tested to perform in tough industrial environments with minimal downtime.

We offer a dry, chemical-free cleaning solution that reduces environmental impact and eliminates the need for hazardous waste disposal.

High-precision laser control delivers uniform cleaning without damaging the underlying material, even on delicate or complex surfaces.

Our systems clean rust, paint, oil, and oxidation on metal, stone, wood, and other materials across multiple industries.

With plug-and-play functionality, ergonomic handheld designs, and optional automation, our machines fit seamlessly into any workflow.

Faster Laser provides training, technical guidance, and after-sales service to ensure smooth operation and long-term value.

8 reviews for FQP-L Laser Cleaning Machine

Bianca –

Stainless steel articulators discolored after repeated firings. Pinpoint laser bursts remove oxide, restoring smooth movement without disassembly. Quiet operation lets technicians converse while scanning crowns. Instrument lifespan extends, and monthly consumable spend fell. The lab’s marketing now touts eco-friendly polish-free restoration services that impress visiting dentists.

Delilah –

Salt crust on hydraulic cylinder rods jeopardized seals. Clamped laser head cleans rods topside, avoiding crane removal. No abrasive grit enters gearboxes, and deckhands sweep minimal debris. Equipment returns to duty on the same shift, reducing standby rentals. Safety officers appreciate zero sparks near volatile fumes during late-night maintenance.

Mariana –

Limestone war memorials carried black crust from decades of traffic exhaust. Controlled laser flares removed soot layer-by-layer, revealing crisp lettering. City officials praised zero runoff near flowerbeds. Crowd barriers stayed minimal because the operation produced little noise. Media coverage brought two additional historic-site contracts within one month.

Sean –

Bulldozer sprockets arrive caked in hardened clay. Laser cleaning blasts debris without high-pressure water, keeping the yard mud-free. Inspectors quickly find cracks for warranty decisions. The single module rolls between bays, and universal presets simplify training. Technicians report improved morale since messy pressure-wash afternoons virtually disappeared.

Jonas –

Graffiti and oxidized primer once required sanders and solvents, delaying hopper turnaround. Mobile laser skid follows the rail spur and cleans surfaces with one operator. Waste drums stand empty; environmental reporting simplifies. Paint contractors praise a consistent profile, reducing recoat defects across three consecutive contracts this fiscal year.

Paige –

Aluminum canning rails build sticky sugar deposits. Laser cleaning vaporizes film without wet chemicals, allowing immediate resumption of the line. Swabs show lower microbial counts, and lube stays cleaner. Downtime previously scheduled weekly now occurs bi-weekly, freeing staff for preventative tasks and boosting throughput ahead of summer demand.

Trevor –

Carbon-fiber lay-up molds accumulate release-agent build-up that distorts surfaces. Low-power laser mode ablates residue without scratching the nickel shell. Surface profilometer readings improved, and parts now meet the thickness spec first lay-up. Maintenance logs show fifty percent fewer mold touch-ups, bolstering our AS9100 scorecard during the recent external audit.

Wesley –

Medieval iron hinges exhibited stable rust unsuitable for acids. Adjustable laser pulses lifted flaky layers while preserving forge marks. The infrared thermometer maintained safe temperatures. Documentation photos taken in real time streamline condition reports. Volunteers learned the operation swiftly, enabling us to treat thirty doors during a single public workshop weekend.