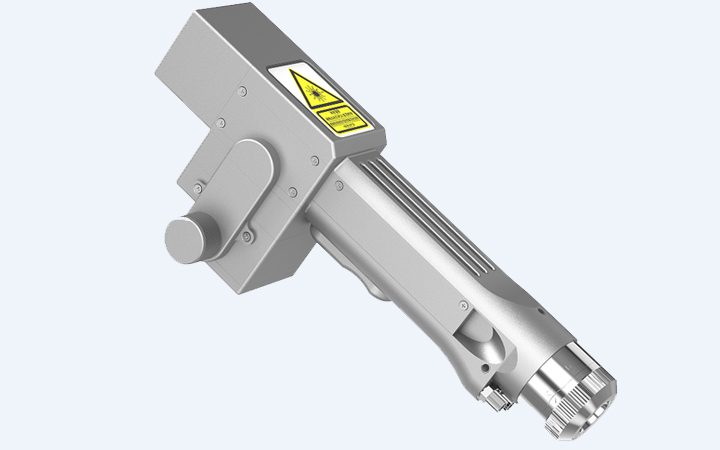

FQP-B Laser Cleaning Machine

The FQP-B laser cleaning machine features a backpack design, battery power, and a wobble laser head for safe, portable, and precise cleaning in remote or confined spaces.

Removes rust and paint without touching the surface, preserving material integrity and preventing abrasion or deformation.

Uses no chemicals, generates minimal waste, and supports sustainable cleaning practices with reduced environmental impact.

Targets only unwanted layers with pinpoint accuracy, leaving the base material untouched—even on delicate or complex surfaces.

Features a sealed design and few moving parts, lowering maintenance time, cost, and machine downtime.

Provides rapid productivity and reduces labor costs for industrial-scale rust removal, coating stripping, and surface preparation.

Equipped with intuitive controls and safety features, making it easy to operate while protecting users from laser exposure.

Yes, the laser cleaning machine allows for the customization of cleaning parameters to meet different material and application needs. Users can adjust several key settings to optimize performance, including laser power, pulsed frequency, scanning speed, beam width, and focal length. Customizable cleaning parameters:

Customizing these parameters ensures optimal cleaning results for different applications, including rust removal, paint stripping, surface preparation, and delicate cleaning of sensitive materials.

Yes, wearing laser safety goggles is essential when operating laser cleaning machines to protect your eyes from harmful laser radiation. Laser cleaning systems, especially high-power fiber lasers, emit intense laser beams that can cause serious eye damage, including retinal burns or permanent vision loss if exposed directly or indirectly through reflections.

Laser safety goggles are mandatory when using laser cleaning machines. Operators should also implement additional safety measures, such as protective enclosures, controlled workspaces, and warning signs, to prevent accidental exposure.

Yes, laser cleaning can produce harmful fumes, depending on the type of material being cleaned and the contaminants present. When a laser beam removes rust, paint, oil, or coatings, it vaporizes the surface material, generating fumes, smoke, and particulate matter that may contain toxic or hazardous substances.

Laser cleaning does produce fumes, and the level of hazard depends on the material being cleaned. Implementing fume extraction, ventilation, and protective equipment is essential to ensure operator safety and maintain a clean working environment.

We offer a comprehensive warranty policy to ensure reliable performance and long-term support for our laser cleaning machines. Below is a detailed breakdown of our warranty coverage, including the warranty period, terms and conditions for different components, and how customers can apply for warranty service.

Our laser cleaning machine has a 3-year warranty on the entire machine, a 2-year warranty on the laser generator, and a 1-year warranty on core components. This structured warranty ensures that customers receive high-quality support and service. To maintain the performance of the machine and extend its life, we recommend regular maintenance and correct operation. If any problems arise, our technical support team can assist with troubleshooting and warranty claims.

Our laser cleaning machines meet international quality, safety, and regulatory standards, ensuring reliability, compliance, and customer confidence. Below is a detailed overview of the key certifications our machines hold and their significance.

Our laser cleaning machines are certified to meet international quality and safety standards, including ISO 9001, CE, and FDA certifications. These certifications ensure that our machines are manufactured with strict quality control, meet European safety regulations, and comply with U.S. laser safety requirements. Customers can be assured of high performance, reliability, and legal compliance when purchasing and operating our machines.

On-site technical support is available for laser cleaning machines, providing customers with hands-on assistance for installation, troubleshooting, training, and maintenance. However, this service comes at an additional cost. The standard service fee is US$200 per day, and customers are also responsible for covering the engineer’s round-trip airfare, board, lodging, and local transportation if required. This ensures that customers receive expert guidance directly at their facility to maximize machine performance and minimize downtime. The process for requesting on-site support involves contacting customer service, providing details of the issue, receiving a cost estimate, and scheduling an engineer visit. While on-site service is a valuable option, customers can also choose remote support, which includes troubleshooting via phone, email, or video calls, as well as access to online training materials and documentation at no additional cost. If in-person assistance is necessary, we are ready to arrange a visit to ensure the machine operates efficiently and reliably.

Our laser cleaning machines are built with premium components and tested to perform in tough industrial environments with minimal downtime.

We offer a dry, chemical-free cleaning solution that reduces environmental impact and eliminates the need for hazardous waste disposal.

High-precision laser control delivers uniform cleaning without damaging the underlying material, even on delicate or complex surfaces.

Our systems clean rust, paint, oil, and oxidation on metal, stone, wood, and other materials across multiple industries.

With plug-and-play functionality, ergonomic handheld designs, and optional automation, our machines fit seamlessly into any workflow.

Faster Laser provides training, technical guidance, and after-sales service to ensure smooth operation and long-term value.

8 reviews for FQP-B Laser Cleaning Machine

Damon –

Decorative railings tarnish under constant touch. Laser cleaner restores shine before park opening without wet residue that stains pavers. Guests never notice maintenance, and photo feedback scores climbed. Reduced polish paste saved custodial supply budget, earning our team recognition at the quarterly leadership luncheon.

Adeline –

Oak barrel hoops show black spot corrosion. Gentle laser settings brighten steel without scorching wood. Water usage in the rinse booth fell sharply, pleasing sustainability auditors. Aroma panels detect zero burnt tannins, and marketing now labels barrels “chemical-free refurbished,” attracting boutique vineyards seeking natural cellar practices.

Sadie –

Chrome bumpers hid under peeling clear coat and surface rust. Laser stripping keeps the contour sharp, unlike wire wheels that round edges. The process runs cool, so the lead filler beneath stays solid. Owners touring the shop love seeing sparks dance without chemicals, sharing videos that market future projects.

Corbin –

Heat-tempered axles must remain dimensionally true. Laser cleaning erases corrosion before nondestructive testing, avoiding abrasive wheels that alter surface hardness. Eddy-current inspection rejects dropped drastically. The machine’s rugged wheels roll along the pit rail, and night shift handles operation confidently after brief video modules.

Kellen –

Cavitation pitting hides under marine growth. Focused laser bursts strip barnacles, exposing damage for welders. No water runoff simplifies EPA paperwork. Customers appreciate faster prop turnaround, and polished blades test smoother in the towing tank, proving value. Crew mentions lighter workload compared with hammer-and-chisel days.

Amelia –

Steel tooling accumulates lacquer overspray. Laser cleaning removes buildup without abrasive pads, preserving critical diameters. Press uptime improved by two hours weekly. Operators rejoice at a quieter environment, and the absence of rogue grit protects nearby bearing grease. Production metrics crossed a new efficiency threshold this quarter.

Brayden –

Aluminum jet-bridge plates showed stubborn rubber skid marks. Handheld laser melts residue quickly without solvents that violate apron regulations. Crew turnover time was shortened, letting passengers disembark faster during peak arrivals. Surface brightness improves lighting, and FOD risk lessens thanks to the debris-free cleaning method.

Alexis –

Bronze sculptures leave the kiln with investment freckles. Laser sweeping removes specks without brushing the patina. Airbrush artists start sooner, shortening customer lead times. Energy bills dipped because burn-out ovens no longer heat for acid cleaning. We completed record commission volume this spring with identical staffing.