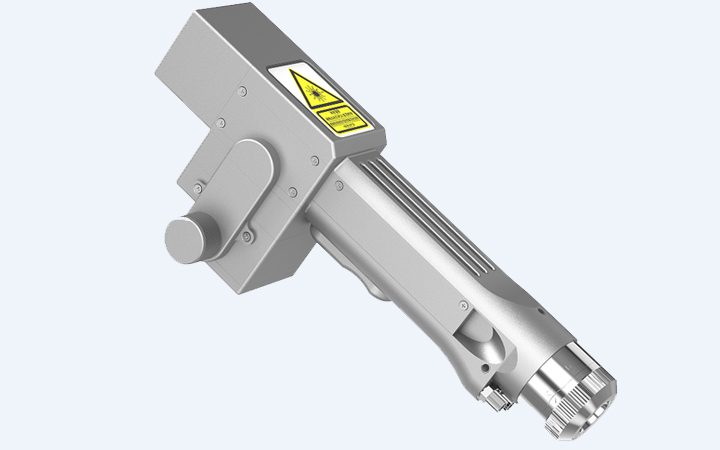

FQ-P Laser Cleaning Machine

The FQ-P laser cleaning machine offers portable, high-precision surface cleaning with a handheld laser head, continuous laser generator, and advanced safety features for versatile applications.

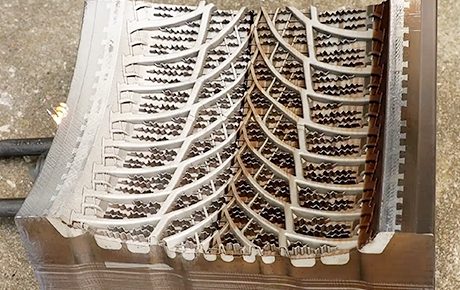

Removes rust and paint without touching the surface, preserving material integrity and preventing abrasion or deformation.

Uses no chemicals, generates minimal waste, and supports sustainable cleaning practices with reduced environmental impact.

Targets only unwanted layers with pinpoint accuracy, leaving the base material untouched—even on delicate or complex surfaces.

Features a sealed design and few moving parts, lowering maintenance time, cost, and machine downtime.

Provides rapid productivity and reduces labor costs for industrial-scale rust removal, coating stripping, and surface preparation.

Equipped with intuitive controls and safety features, making it easy to operate while protecting users from laser exposure.

Yes, the laser cleaning machine allows for the customization of cleaning parameters to meet different material and application needs. Users can adjust several key settings to optimize performance, including laser power, pulse frequency, scanning speed, beam width, and focal length. Customizable cleaning parameters:

Customizing these parameters ensures optimal cleaning results for different applications, including rust removal, paint stripping, surface preparation, and delicate cleaning of sensitive materials.

Yes, wearing laser safety goggles is essential when operating laser cleaning machines to protect your eyes from harmful laser radiation. Laser cleaning systems, especially high-power fiber lasers, emit intense laser beams that can cause serious eye damage, including retinal burns or permanent vision loss if exposed directly or indirectly through reflections.

Laser safety goggles are mandatory when using laser cleaning machines. Operators should also implement additional safety measures, such as protective enclosures, controlled workspaces, and warning signs, to prevent accidental exposure.

Yes, laser cleaning can produce harmful fumes, depending on the type of material being cleaned and the contaminants present. When a laser beam removes rust, paint, oil, or coatings, it vaporizes the surface material, generating fumes, smoke, and particulate matter that may contain toxic or hazardous substances.

Laser cleaning does produce fumes, and the level of hazard depends on the material being cleaned. Implementing fume extraction, ventilation, and protective equipment is essential to ensure operator safety and maintain a clean working environment.

We offer a comprehensive warranty policy to ensure reliable performance and long-term support for our laser cleaning machines. Below is a detailed breakdown of our warranty coverage, including the warranty period, terms and conditions for different components, and how customers can apply for warranty service.

Our laser cleaning machine has a 3-year warranty on the entire machine, a 2-year warranty on the laser generator, and a 1-year warranty on core components. This structured warranty ensures that customers receive high-quality support and service. To maintain the performance of the machine and extend its life, we recommend regular maintenance and correct operation. If any problems arise, our technical support team can assist with troubleshooting and warranty claims.

Our laser cleaning machines meet international quality, safety, and regulatory standards, ensuring reliability, compliance, and customer confidence. Below is a detailed overview of the key certifications our machines hold and their significance.

Our laser cleaning machines are certified to meet international quality and safety standards, including ISO 9001, CE, and FDA certifications. These certifications ensure that our machines are manufactured with strict quality control, meet European safety regulations, and comply with U.S. laser safety requirements. Customers can be assured of high performance, reliability, and legal compliance when purchasing and operating our machines.

On-site technical support is available for laser cleaning machines, providing customers with hands-on assistance for installation, troubleshooting, training, and maintenance. However, this service comes at an additional cost. The standard service fee is US$200 per day, and customers are also responsible for covering the engineer’s round-trip airfare, board, lodging, and local transportation if required. This ensures that customers receive expert guidance directly at their facility to maximize machine performance and minimize downtime. The process for requesting on-site support involves contacting customer service, providing details of the issue, receiving a cost estimate, and scheduling an engineer visit. While on-site service is a valuable option, customers can also choose remote support, which includes troubleshooting via phone, email, or video calls, as well as access to online training materials and documentation at no additional cost. If in-person assistance is necessary, we are ready to arrange a visit to ensure the machine operates efficiently and reliably.

Our laser cleaning machines are built with premium components and tested to perform in tough industrial environments with minimal downtime.

We offer a dry, chemical-free cleaning solution that reduces environmental impact and eliminates the need for hazardous waste disposal.

High-precision laser control delivers uniform cleaning without damaging the underlying material, even on delicate or complex surfaces.

Our systems clean rust, paint, oil, and oxidation on metal, stone, wood, and other materials across multiple industries.

With plug-and-play functionality, ergonomic handheld designs, and optional automation, our machines fit seamlessly into any workflow.

Faster Laser provides training, technical guidance, and after-sales service to ensure smooth operation and long-term value.

8 reviews for FQ-P Laser Cleaning Machine

Ella –

Our injection molds accumulate burnt polymer at parting lines. Laser cleaning strips residue quickly while tooling remains on the press, saving crane time. Mirror finish stays intact, and part flash issues disappeared. Cycle count between shutdowns is extended, translating directly into higher output and happier automotive customers ordering dashboards this quarter.

Gavin –

Wind turbine gearboxes suffer from burnt oil stains that trap debris. Portable laser cleaning restores surfaces in the nacelle, avoiding crane removal. Technicians appreciate the low weight and long fiber cable. Vibration sensors show smoother run-in afterward, and scheduled downtime decreased by one full day across our fleet this maintenance season already.

Penelope –

Historic wooden doors had iron hinges coated in flaky lead paint. The laser cleaner vaporized coatings precisely while infrared shields protected oak fibers. Air samples confirmed safe lead capture. Residents admired the odorless process, and contractors avoided scaffold dismantling thanks to the tool’s reach, shaving two days off the schedule easily.

Malik –

Pipeline refurbishment crews dreaded sandblasting inside tunnels. The laser cleaner’s narrow beam removes rust, leaving a lightly roughened surface ideal for epoxy without generating airborne grit. Ventilation load fell, and communication improved. Productivity jumped, and management credited fewer fatigue incidents to the cleaner, brighter workspace created during operations recently, too.

Noah –

Statue cleaning in busy plazas requires portable equipment and minimal mess. The laser unit runs off a small generator and leaves only faint smoke, easily captured by a simple hood. Pedestrians stay curious instead of annoyed. City officials praised the quiet operation, and we secured another five monuments contract today.

Jade –

Printed-circuit rework demanded that flux residue be gone before conformal coating. Micro-spot laser cleaning removes char without disturbing fragile pads. Lab microscopes confirm no copper lift. Technicians like the joystick control and quick focus changes. Rejects decreased, and we shipped the last board lot two days earlier than the customer forecast this month.

Isabelle –

Museum artifacts cannot withstand abrasive pads. Gentle laser settings lift corrosive layers from bronze coins under glass, while temperature sensors prevent overheating. Conservators watch progress on a tablet and annotate each pass. The streamlined workflow cut handling time, letting us document twice as many pieces during our seasonal exhibition prep.

Damian –

The heritage commission insisted that stone carvings remain intact while removing decades of soot. Gentle laser pulses lifted grime without etching, revealing crisp chisel marks again. Historians applauded, and our crew worked mask-free because no dust filled the chapel. Project finished ahead of schedule, earning valuable referrals for future restorations too.