FQ Laser Cleaning Machine

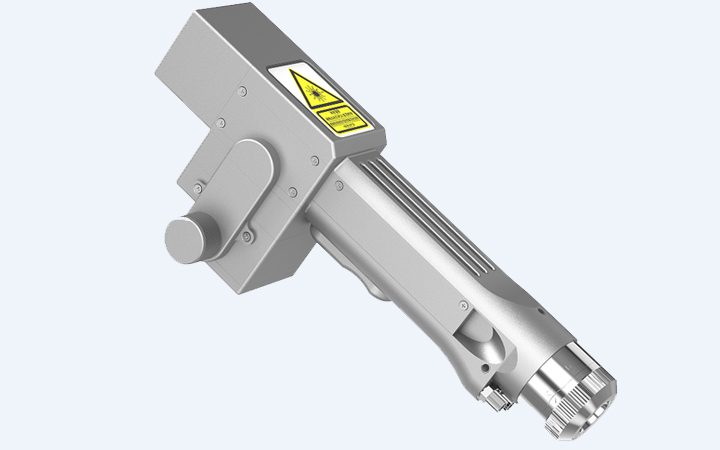

The FQ laser cleaning machine offers portable, high-efficiency surface cleaning with a handheld laser head, continuous laser generator, and advanced safety features for various industries.

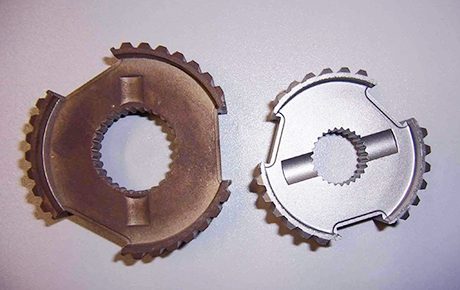

Removes rust and paint without touching the surface, preserving material integrity and preventing abrasion or deformation.

Uses no chemicals, generates minimal waste, and supports sustainable cleaning practices with reduced environmental impact.

Targets only unwanted layers with pinpoint accuracy, leaving the base material untouched—even on delicate or complex surfaces.

Features a sealed design and few moving parts, lowering maintenance time, cost, and machine downtime.

Provides rapid productivity and reduces labor costs for industrial-scale rust removal, coating stripping, and surface preparation.

Equipped with intuitive controls and safety features, making it easy to operate while protecting users from laser exposure.

Yes, the laser cleaning machine allows for the customization of cleaning parameters to meet different material and application needs. Users can adjust several key settings to optimize performance, including laser power, pulse frequency, scanning speed, beam width, and focal length. Customizable cleaning parameters:

Customizing these parameters ensures optimal cleaning results for different applications, including rust removal, paint stripping, surface preparation, and delicate cleaning of sensitive materials.

Yes, wearing laser safety goggles is essential when operating laser cleaning machines to protect your eyes from harmful laser radiation. Laser cleaning systems, especially high-power fiber lasers, emit intense laser beams that can cause serious eye damage, including retinal burns or permanent vision loss if exposed directly or indirectly through reflections.

Laser safety goggles are mandatory when using laser cleaning machines. Operators should also implement additional safety measures, such as protective enclosures, controlled workspaces, and warning signs, to prevent accidental exposure.

Yes, laser cleaning can produce harmful fumes, depending on the type of material being cleaned and the contaminants present. When a laser beam removes rust, paint, oil, or coatings, it vaporizes the surface material, generating fumes, smoke, and particulate matter that may contain toxic or hazardous substances.

Laser cleaning does produce fumes, and the level of hazard depends on the material being cleaned. Implementing fume extraction, ventilation, and protective equipment is essential to ensure operator safety and maintain a clean working environment.

We offer a comprehensive warranty policy to ensure reliable performance and long-term support for our laser cleaning machines. Below is a detailed breakdown of our warranty coverage, including the warranty period, terms and conditions for different components, and how customers can apply for warranty service.

Our laser cleaning machine has a 3-year warranty on the entire machine, a 2-year warranty on the laser generator, and a 1-year warranty on core components. This structured warranty ensures that customers receive high-quality support and service. To maintain the performance of the machine and extend its life, we recommend regular maintenance and correct operation. If any problems arise, our technical support team can assist with troubleshooting and warranty claims.

Our laser cleaning machines meet international quality, safety, and regulatory standards, ensuring reliability, compliance, and customer confidence. Below is a detailed overview of the key certifications our machines hold and their significance.

Our laser cleaning machines are certified to meet international quality and safety standards, including ISO 9001, CE, and FDA certifications. These certifications ensure that our machines are manufactured with strict quality control, meet European safety regulations, and comply with U.S. laser safety requirements. Customers can be assured of high performance, reliability, and legal compliance when purchasing and operating our machines.

On-site technical support is available for laser cleaning machines, providing customers with hands-on assistance for installation, troubleshooting, training, and maintenance. However, this service comes at an additional cost. The standard service fee is US$200 per day, and customers are also responsible for covering the engineer’s round-trip airfare, board, lodging, and local transportation if required. This ensures that customers receive expert guidance directly at their facility to maximize machine performance and minimize downtime. The process for requesting on-site support involves contacting customer service, providing details of the issue, receiving a cost estimate, and scheduling an engineer visit. While on-site service is a valuable option, customers can also choose remote support, which includes troubleshooting via phone, email, or video calls, as well as access to online training materials and documentation at no additional cost. If in-person assistance is necessary, we are ready to arrange a visit to ensure the machine operates efficiently and reliably.

Our laser cleaning machines are built with premium components and tested to perform in tough industrial environments with minimal downtime.

We offer a dry, chemical-free cleaning solution that reduces environmental impact and eliminates the need for hazardous waste disposal.

High-precision laser control delivers uniform cleaning without damaging the underlying material, even on delicate or complex surfaces.

Our systems clean rust, paint, oil, and oxidation on metal, stone, wood, and other materials across multiple industries.

With plug-and-play functionality, ergonomic handheld designs, and optional automation, our machines fit seamlessly into any workflow.

Faster Laser provides training, technical guidance, and after-sales service to ensure smooth operation and long-term value.

8 reviews for FQ Laser Cleaning Machine

Olivia –

Graffiti removal contracts used to involve harsh solvents and noise restrictions in residential areas. The laser cleaner erases paint quietly, creating no runoff. Homeowners watch the brick surface emerge undamaged and book extra work on the spot. Evening appointments doubled because we no longer disturb sleeping kids or pets nearby.

Caleb –

Our shop removes heavy oil and paint from mold plates daily. The handheld laser cleaner strips to bare metal in seconds without chemicals or media. Noise is low, and there’s no dust cloud. Filters last much longer since nothing abrasive circulates. Downtime dropped and safety reports improved across the entire week.

Hannah –

Our brewery plates are fouled with beer stone regularly. The laser cleaner vaporizes deposits without chemicals, so we protect stainless steek passivation layers and skip lengthy rinses. Water usage plummeted, aligning perfectly with our sustainability goals. Sanitization verification swabs show cleaner surfaces, and we regained two productive hours each maintenance cycle weekly.

Victor –

We service turbine blades, and abrasive blasting risks dimensional change. The portable laser cleaner removes carbon deposits precisely, while the temperature monitor protects base alloys. Field technicians value the lightweight gun and simple presets. Inspection pass rate rose, and we eliminated grit contamination inside bearing housings, extending overhaul intervals noticeably.

Leo –

Before painting garden gates, we sanded for hours. Now the laser cleaner removes mill scale and old coatings in one smooth pass, even inside scrollwork. Power settings are intuitive, and the cooling fans run quietly. Customers notice a crisper finish, and my crew’s elbows thank me every single Friday afternoon for sure.

Amelia –

Restoring antique brass fixtures was messy with chemical baths. The laser cleaner lifts oxidation evenly, leaving a bright surface ready for lacquer without scrubbing. Clients appreciate the lack of odor, and my employees avoid harsh solvents. Turnaround time halved, and disposal costs almost entirely disappeared during our busiest quarter recently.

Marcus –

The automotive line struggled with weld spatter cleanup. Laser cleaning zaps residue between stations without touching paint, allowing robots to continue working. Programming presets switch automatically via Ethernet, simplifying integration. Scrap dropped, and inspectors praised the pristine seams. Even finance recognized the immediate cost savings on consumables and rework yesterday.

Serena –

Shipyard steel plates arrive coated with thick rust from months at sea. The laser cleaner strips each panel fast, producing no secondary waste, so deck hands sweep instead of shoveling grit. Visibility stays clear, improving safety. Daily productivity targets jumped, and environmental officers endorsed our new surface preparation process immediately.