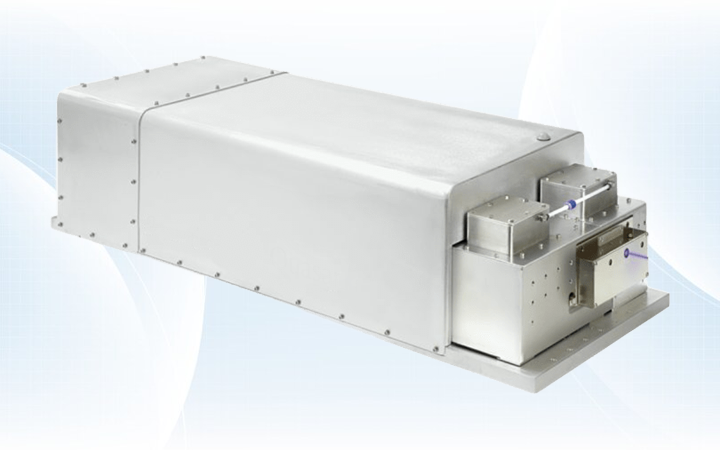

FM-US Laser Marking Machine

The FM-US laser marking machine features a split design and UV laser for precise, high-contrast marking on plastics, glass, ceramics, and coated materials with fast, accurate results.

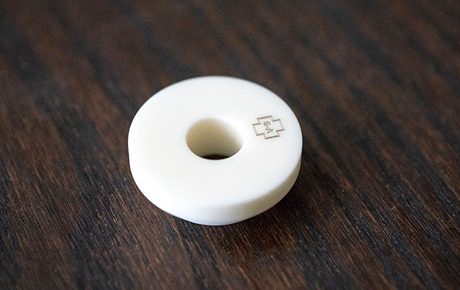

Uses a short-wavelength beam to create highly detailed, crisp marks—ideal for micro-marking on sensitive materials.

Generates minimal heat, preventing damage, warping, or burning on delicate surfaces such as plastics, glass, ceramics, and thin films.

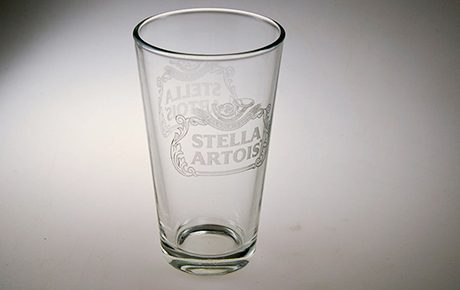

Achieves strong contrast and readability even on transparent or soft materials without causing surface degradation.

Marks a broad range of substrates, including glass, sapphire, polymer films, and coated metals with superior clarity and precision.

Chemical-free, low-power consumption process reduces environmental impact while maintaining high-quality results.

Delivers consistent performance with pinpoint accuracy, ideal for industries requiring exact traceability.

Yes, laser marking is safe when proper safety precautions are followed. Unlike laser cutting or welding, laser marking operates at lower power levels and does not produce high heat, sparks, or molten material. However, laser radiation, fumes, and reflections still pose potential risks, making protective measures essential. Potential security risks and their mitigation methods are as follows:

Laser marking is safe when operated with proper enclosures, protective eyewear, fume extraction, and workplace safety measures. Most modern fiber, CO2, MOPA, and UV laser marking machines are designed with built-in safety features, making them suitable for industrial and commercial use with minimal risk.

Laser marks are highly permanent and offer superior durability compared to traditional marking methods like ink printing, engraving, or etching. The permanence of a laser mark depends on material type, marking method, and environmental exposure, but in most cases, laser markings remain intact for a lifetime. The factors that affect the durability of laser marking are as follows:

Laser marks are one of the most permanent marking solutions, lasting years to a lifetime depending on material and usage conditions. Deep engraving, annealing, and high-contrast marking methods ensure resistance to wear, heat, chemicals, and UV exposure, making laser marking ideal for industrial, medical, aerospace, and consumer applications.

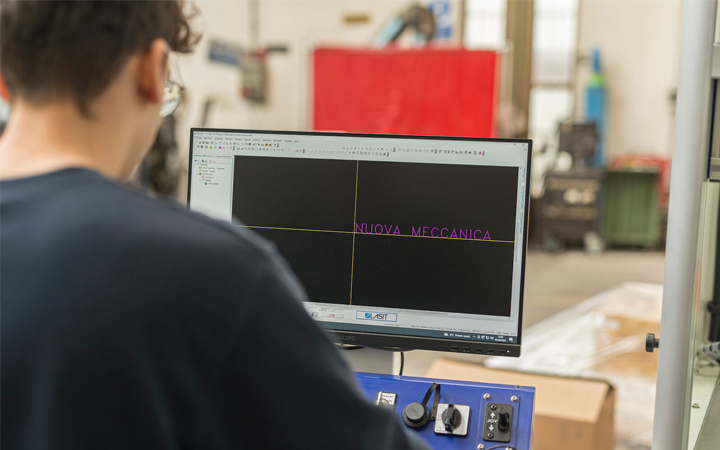

Laser marking machines support a variety of vector and raster file formats to ensure compatibility with different design software. The most commonly supported file formats include:

Laser marking machines are compatible with vector files (DXF, AI, PLT, SVG, PDF), raster images (BMP, JPG, PNG, TIFF), and CAD formats (DWG, G-Code). Vector files are recommended for precision engraving, while raster files are ideal for photographic or grayscale engraving. Always check the machine’s software for specific format support.

We offer a comprehensive warranty policy to ensure reliable performance and long-term support for our laser marking machines. Below is a detailed breakdown of our warranty coverage, including the warranty period, terms and conditions for different components, and how customers can apply for warranty service.

Our laser marking machine has a 3-year warranty on the entire machine, a 2-year warranty on the laser generator, and a 1-year warranty on core components. This structured warranty ensures that customers receive high-quality support and service. To maintain the performance of the machine and extend its life, we recommend regular maintenance and correct operation. If any problems arise, our technical support team can assist with troubleshooting and warranty claims.

Our laser marking machines meet international quality, safety, and regulatory standards, ensuring reliability, compliance, and customer confidence. Below is a detailed overview of the key certifications our machines hold and their significance.

Our laser marking machines are certified to meet international quality and safety standards, including ISO 9001, CE, and FDA certifications. These certifications ensure that our machines are manufactured with strict quality control, meet European safety regulations, and comply with U.S. laser safety requirements. Customers can be assured of high performance, reliability, and legal compliance when purchasing and operating our machines.

On-site technical support is available for laser marking machines, providing customers with hands-on assistance for installation, troubleshooting, training, and maintenance. However, this service comes at an additional cost. The standard service fee is US$200 per day, and customers are also responsible for covering the engineer’s round-trip airfare, board, lodging, and local transportation if required. This ensures that customers receive expert guidance directly at their facility to maximize machine performance and minimize downtime. The process for requesting on-site support involves contacting customer service, providing details of the issue, receiving a cost estimate, and scheduling an engineer visit. While on-site service is a valuable option, customers can also choose remote support, which includes troubleshooting via phone, email, or video calls, as well as access to online training materials and documentation at no additional cost. If in-person assistance is necessary, we are ready to arrange a visit to ensure the machine operates efficiently and reliably.

Our machines deliver ultra-fine marking and engraving with high-speed galvanometer systems and stable laser sources for consistent, reliable output.

We offer different laser types to match your needs, ensuring crisp, permanent marks on metal, plastic, wood, leather, and more.

Intuitive control software allows easy setup, flexible design import, and precise marking even for first-time users.

We provide machine options tailored to your product size, line speed, and marking content for seamless integration.

Our systems run cleanly with no inks or chemicals, lowering long-term operating costs and environmental impact.

Faster Laser offers professional training, remote troubleshooting, and responsive service to keep your production running smoothly.

8 reviews for FM-US Laser Marking Machine

Wesley –

I make luxury pens using acrylic barrels. The UV engraver produces sharp signatures without frosting adjacent areas. Swapping to a larger field lens for presentation boxes takes seconds. Built-in job counter tracks usage for billing projects. Compared to outsourcing, I now deliver custom orders in days instead of weeks.

Violet –

Our eyewear line requires tiny etchings on lens edges. The UV laser’s fine spot handles six-point text with ease. Rotary adapter centers curved blanks without slip. Cooling fan noise is low, important for our design studio ambience. Customers appreciate discreet branding that never scratches off during daily cleaning.

Xander –

We label polypropylene lab vials. The beam creates crisp white codes that endure ethanol baths. Bulk loader tray feeds fifty at once, freeing staff for other tasks. Touchscreen UI supports multiple languages, useful for our diverse team. Remote firmware upgrade added barcode preview, showing commitment to ongoing improvements.

Talia –

Our packaging line marks tamper-proof seals. UV coding stands out clearly under blacklight for inspectors but is invisible to consumers. The compact frame mounts above the conveyor, and I/O ports link to existing sensors. Since integration, verification speed improved, and we eliminated ink cartridge waste entirely, which helps sustainability goals.

Uri –

I run a small prototyping studio. This machine engraves polyimide flex circuits with trace labels, resisting soldering heat. Camera alignment finds board corners automatically, saving tape fixtures. The enclosed design means no smell drifts into office space. After six months, beam power drift measured under one percent—remarkably stable.

Rosa –

Our lab creates microfluidic chips. The UV source drills vent holes under 100 microns without cracking PMMA. Parametric script runs multiple depths in one cycle. Cooling loop is sealed, so no algae forms. Documentation includes suggested settings for common plastics, which helped us hit targets quickly and preserve research time.

Spencer –

I engrave musical instrument reeds. The machine gives a subtle frosted finish on resin composite without affecting tone. Foot pedal trigger lets me keep hands steady on delicate parts. Lens change requires no tools, and presets recall previous focus height. Musicians comment that the markings stay legible even after moisture exposure.

Quinn –

We needed data matrix marks on nylon gears. The cold beam avoids bloom typical with CO2. Air assist keeps debris away, and extraction tubing clips securely to existing ducts. Job queue feature manages mixed part runs, letting one operator oversee several cells. Maintenance checklist is simple and takes five minutes daily.