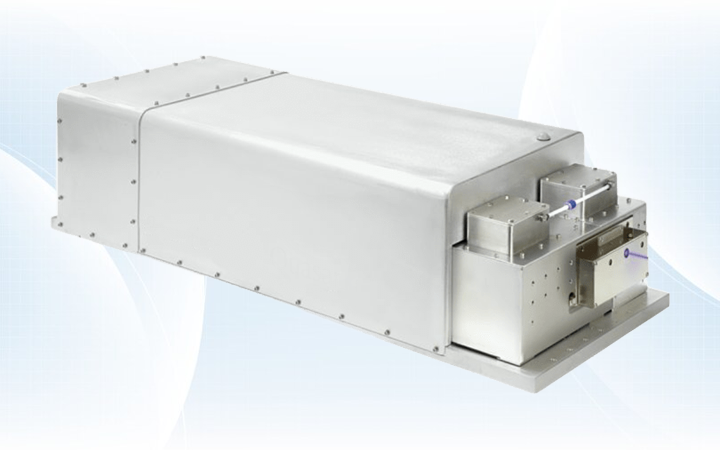

FM-UH Laser Marking Machine

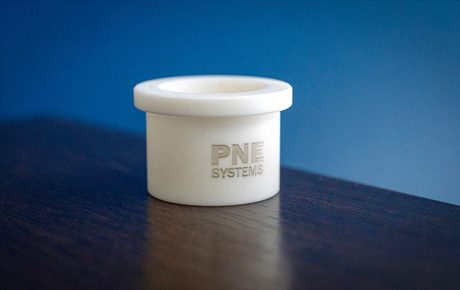

The FM-UH laser marking machine features a handheld design and UV laser for precise, high-contrast marking on plastics, glass, and ceramics, with fast, accurate, and portable engraving.

Uses a short-wavelength beam to create highly detailed, crisp marks—ideal for micro-marking on sensitive materials.

Generates minimal heat, preventing damage, warping, or burning on delicate surfaces such as plastics, glass, ceramics, and thin films.

Achieves strong contrast and readability even on transparent or soft materials without causing surface degradation.

Marks a broad range of substrates, including glass, sapphire, polymer films, and coated metals with superior clarity and precision.

Chemical-free, low-power consumption process reduces environmental impact while maintaining high-quality results.

Delivers consistent performance with pinpoint accuracy, ideal for industries requiring exact traceability.

Yes, laser marking is safe when proper safety precautions are followed. Unlike laser cutting or welding, laser marking operates at lower power levels and does not produce high heat, sparks, or molten material. However, laser radiation, fumes, and reflections still pose potential risks, making protective measures essential. Potential security risks and their mitigation methods are as follows:

Laser marking is safe when operated with proper enclosures, protective eyewear, fume extraction, and workplace safety measures. Most modern fiber, CO2, MOPA, and UV laser marking machines are designed with built-in safety features, making them suitable for industrial and commercial use with minimal risk.

Laser marks are highly permanent and offer superior durability compared to traditional marking methods like ink printing, engraving, or etching. The permanence of a laser mark depends on material type, marking method, and environmental exposure, but in most cases, laser markings remain intact for a lifetime. The factors that affect the durability of laser marking are as follows:

Laser marks are one of the most permanent marking solutions, lasting years to a lifetime depending on material and usage conditions. Deep engraving, annealing, and high-contrast marking methods ensure resistance to wear, heat, chemicals, and UV exposure, making laser marking ideal for industrial, medical, aerospace, and consumer applications.

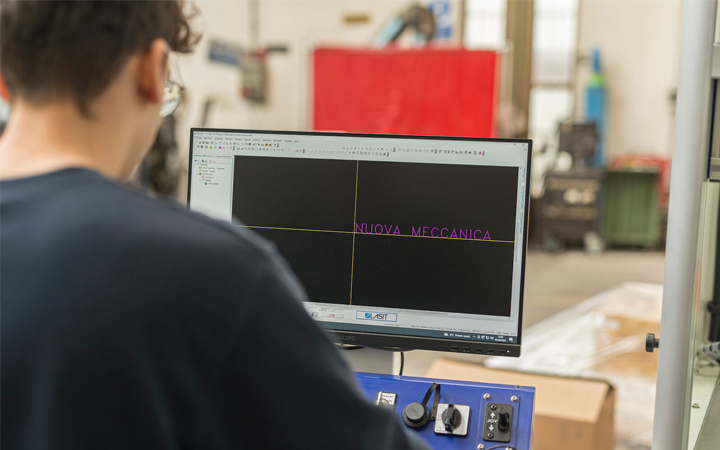

design software. The most commonly supported file formats include:

Laser marking machines are compatible with vector files (DXF, AI, PLT, SVG, PDF), raster images (BMP, JPG, PNG, TIFF), and CAD formats (DWG, G-Code). Vector files are recommended for precision engraving, while raster files are ideal for photographic or grayscale engraving. Always check the machine’s software for specific format support.

We offer a comprehensive warranty policy to ensure reliable performance and long-term support for our laser marking machines. Below is a detailed breakdown of our warranty coverage, including the warranty period, terms and conditions for different components, and how customers can apply for warranty service.

Our laser marking machine has a 3-year warranty on the entire machine, a 2-year warranty on the laser generator, and a 1-year warranty on core components. This structured warranty ensures that customers receive high-quality support and service. To maintain the performance of the machine and extend its life, we recommend regular maintenance and correct operation. If any problems arise, our technical support team can assist with troubleshooting and warranty claims.

Our laser marking machines meet international quality, safety, and regulatory standards, ensuring reliability, compliance, and customer confidence. Below is a detailed overview of the key certifications our machines hold and their significance.

Our laser marking machines are certified to meet international quality and safety standards, including ISO 9001, CE, and FDA certifications. These certifications ensure that our machines are manufactured with strict quality control, meet European safety regulations, and comply with U.S. laser safety requirements. Customers can be assured of high performance, reliability, and legal compliance when purchasing and operating our machines.

On-site technical support is available for laser marking machines, providing customers with hands-on assistance for installation, troubleshooting, training, and maintenance. However, this service comes at an additional cost. The standard service fee is US$200 per day, and customers are also responsible for covering the engineer’s round-trip airfare, board, lodging, and local transportation if required. This ensures that customers receive expert guidance directly at their facility to maximize machine performance and minimize downtime. The process for requesting on-site support involves contacting customer service, providing details of the issue, receiving a cost estimate, and scheduling an engineer visit. While on-site service is a valuable option, customers can also choose remote support, which includes troubleshooting via phone, email, or video calls, as well as access to online training materials and documentation at no additional cost. If in-person assistance is necessary, we are ready to arrange a visit to ensure the machine operates efficiently and reliably.

Our machines deliver ultra-fine marking and engraving with high-speed galvanometer systems and stable laser sources for consistent, reliable output.

We offer different laser types to match your needs, ensuring crisp, permanent marks on metal, plastic, wood, leather, and more.

Intuitive control software allows easy setup, flexible design import, and precise marking even for first-time users.

We provide machine options tailored to your product size, line speed, and marking content for seamless integration.

Our systems run cleanly with no inks or chemicals, lowering long-term operating costs and environmental impact.

Faster Laser offers professional training, remote troubleshooting, and responsive service to keep your production running smoothly.

8 reviews for FM-UH Laser Marking Machine

Kyle –

I run a craft store booth. This laser etches intricate snowflakes on clear ornaments, and edges stay smooth. The preview outline helps me position designs quickly for walk-in customers. Noise level is low, so conversations flow. Sales climbed because buyers watch their pieces made live and share videos online.

Piper –

I sell custom keycaps. The UV marker ablates legends on PBT plastic cleanly, no yellowing. Batch fixtures hold 100 caps, and cycle time per set is less than ten minutes. Preview laser projects patterns so I avoid misplacements. Online forums praised the sharp lettering, bringing me a flood of preorders.

Miguel –

I teach design at a community college. Students use the UV laser to decorate acrylic phone stands. The interface resembles common graphics tools, lowering the learning curve. Safety interlock and tinted lid satisfy campus rules. Despite heavy semester use, focus accuracy remains spot on, proving robust mechanics and optics.

Jasmine –

Our automotive lab needed VIN microtext on head-up display glass. The UV machine writes hairline fonts that remain invisible until backlit, meeting security standards. Vibration isolation feet stop distortions even next to stamping presses. Remote support adjusted pulse width over video call, demonstrating solid customer care without travel delays.

Leah –

Our semiconductor fab labels fragile silicon wafers. The non-thermal UV beam marks ID codes without introducing micro-cracks. Clean enclosure and HEPA exhaust keep particles below spec. Firmware logs each pulse count, supporting traceability audits. Since commissioning, downtime due to marker issues dropped to practically nothing, pleasing the production manager.

Owen –

Our smart watch factory needs serials on sapphire lenses. The UV beam delivers microdepth codes that survive polishing. Built-in power meter allows quick calibration checks each shift. The machine sits within an ISO-7 cleanroom and passes particle tests every inspection. Warranty paperwork was straightforward, and spare parts arrived quickly.

Ivan –

Working at a biotech startup, we mark pipette tips in bulk. The galvo scans so fast that one box finishes in minutes. Autofocus tracks slight height differences, ensuring uniform depth. Chiller alarm has never gone off, showing good cooling design. Consumable costs are basically just lens wipes and filter pads.

Naomi –

We craft award plaques from coated glass. The laser produces frosted text behind the coating, giving a premium look. Alignment camera speeds multi-layer work, and the bed height adjusts electrically, saving backs. Customers now choose glass over metal thanks to refined details, which grew average order value noticeably.