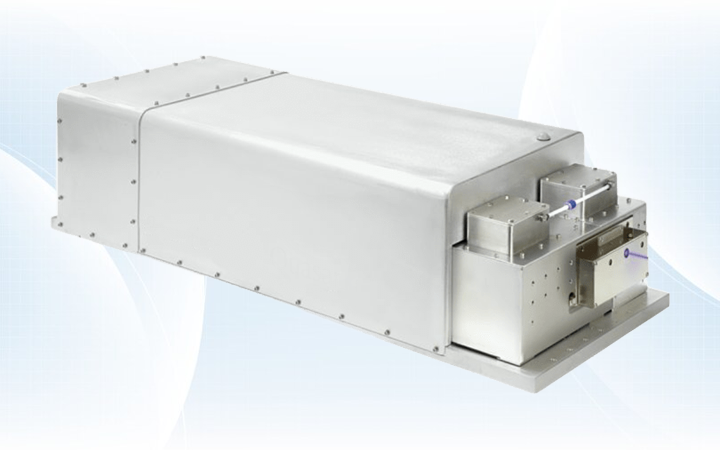

FM-UD Laser Marking Machine

The FM-UD laser marking machine features a desktop design and UV laser for precise, high-contrast marking on plastics, glass, and ceramics with excellent detail and no thermal damage.

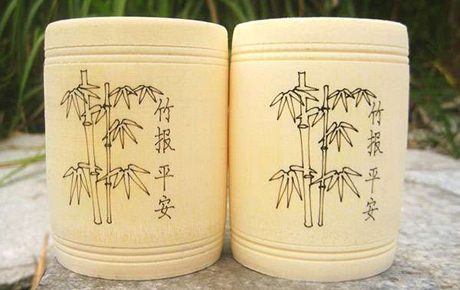

Uses a short-wavelength beam to create highly detailed, crisp marks—ideal for micro-marking on sensitive materials.

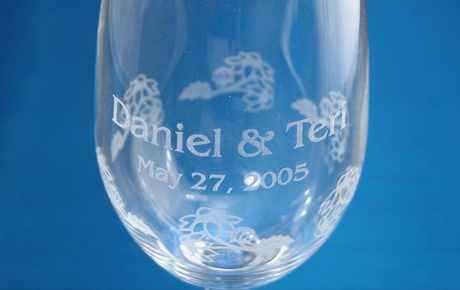

Generates minimal heat, preventing damage, warping, or burning on delicate surfaces such as plastics, glass, ceramics, and thin films.

Achieves strong contrast and readability even on transparent or soft materials without causing surface degradation.

Marks a broad range of substrates, including glass, sapphire, polymer films, and coated metals with superior clarity and precision.

Chemical-free, low-power consumption process reduces environmental impact while maintaining high-quality results.

Delivers consistent performance with pinpoint accuracy, ideal for industries requiring exact traceability.

Yes, laser marking is safe when proper safety precautions are followed. Unlike laser cutting or welding, laser marking operates at lower power levels and does not produce high heat, sparks, or molten material. However, laser radiation, fumes, and reflections still pose potential risks, making protective measures essential. Potential security risks and their mitigation methods are as follows:

Laser marking is safe when operated with proper enclosures, protective eyewear, fume extraction, and workplace safety measures. Most modern fiber, CO2, MOPA, and UV laser marking machines are designed with built-in safety features, making them suitable for industrial and commercial use with minimal risk.

Laser marks are highly permanent and offer superior durability compared to traditional marking methods like ink printing, engraving, or etching. The permanence of a laser mark depends on material type, marking method, and environmental exposure, but in most cases, laser markings remain intact for a lifetime. The factors that affect the durability of laser marking are as follows:

Laser marks are one of the most permanent marking solutions, lasting years to a lifetime depending on material and usage conditions. Deep engraving, annealing, and high-contrast marking methods ensure resistance to wear, heat, chemicals, and UV exposure, making laser marking ideal for industrial, medical, aerospace, and consumer applications.

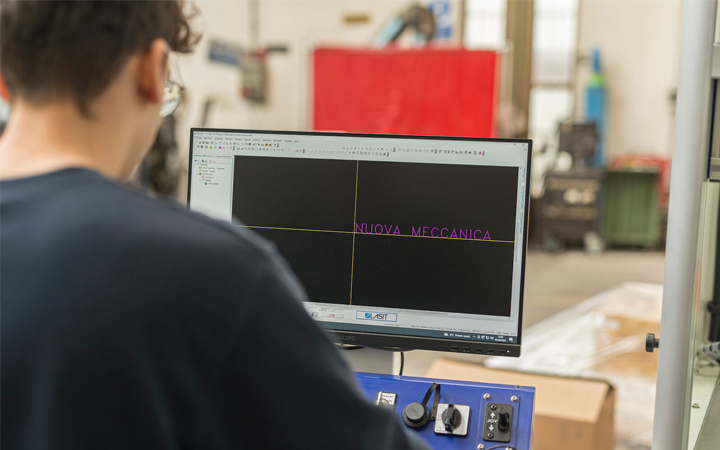

Laser marking machines support a variety of vector and raster file formats to ensure compatibility with different design software. The most commonly supported file formats include:

Laser marking machines are compatible with vector files (DXF, AI, PLT, SVG, PDF), raster images (BMP, JPG, PNG, TIFF), and CAD formats (DWG, G-Code). Vector files are recommended for precision engraving, while raster files are ideal for photographic or grayscale engraving. Always check the machine’s software for specific format support.

We offer a comprehensive warranty policy to ensure reliable performance and long-term support for our laser marking machines. Below is a detailed breakdown of our warranty coverage, including the warranty period, terms and conditions for different components, and how customers can apply for warranty service.

Our laser marking machine has a 3-year warranty on the entire machine, a 2-year warranty on the laser generator, and a 1-year warranty on core components. This structured warranty ensures that customers receive high-quality support and service. To maintain the performance of the machine and extend its life, we recommend regular maintenance and correct operation. If any problems arise, our technical support team can assist with troubleshooting and warranty claims.

Our laser marking machines meet international quality, safety, and regulatory standards, ensuring reliability, compliance, and customer confidence. Below is a detailed overview of the key certifications our machines hold and their significance.

Our laser marking machines are certified to meet international quality and safety standards, including ISO 9001, CE, and FDA certifications. These certifications ensure that our machines are manufactured with strict quality control, meet European safety regulations, and comply with U.S. laser safety requirements. Customers can be assured of high performance, reliability, and legal compliance when purchasing and operating our machines.

On-site technical support is available for laser marking machines, providing customers with hands-on assistance for installation, troubleshooting, training, and maintenance. However, this service comes at an additional cost. The standard service fee is US$200 per day, and customers are also responsible for covering the engineer’s round-trip airfare, board, lodging, and local transportation if required. This ensures that customers receive expert guidance directly at their facility to maximize machine performance and minimize downtime. The process for requesting on-site support involves contacting customer service, providing details of the issue, receiving a cost estimate, and scheduling an engineer visit. While on-site service is a valuable option, customers can also choose remote support, which includes troubleshooting via phone, email, or video calls, as well as access to online training materials and documentation at no additional cost. If in-person assistance is necessary, we are ready to arrange a visit to ensure the machine operates efficiently and reliably.

Our machines deliver ultra-fine marking and engraving with high-speed galvanometer systems and stable laser sources for consistent, reliable output.

We offer different laser types to match your needs, ensuring crisp, permanent marks on metal, plastic, wood, leather, and more.

Intuitive control software allows easy setup, flexible design import, and precise marking even for first-time users.

We provide machine options tailored to your product size, line speed, and marking content for seamless integration.

Our systems run cleanly with no inks or chemicals, lowering long-term operating costs and environmental impact.

Faster Laser offers professional training, remote troubleshooting, and responsive service to keep your production running smoothly.

8 reviews for FM-UD Laser Marking Machine

Gavin –

Our PCB plant marks solder masks with date codes. The ultraviolet beam leaves crisp characters between fine tracks without carbonizing the resin. Built-in camera aligns artwork to fiducials, shortening setup times. We linked the control software to our MES, so each board receives the correct serial automatically, reducing workplace errors.

Ethan –

Our research group labels quartz cuvettes for spectrometry. The UV machine engraves readable text only microns deep, preserving optical clarity. The rotary fixture holds round tubes steadily, allowing full circumference ID. Integrated exhaust captures faint fumes, so the cleanroom stays within spec. Training new students took less than one afternoon.

Fiona –

As a jewelry maker, I need neat logo marks on acrylic pendants. The UV laser delivers bright white contrast without melting edges like CO2 did. Focus probe is fast and accurate, letting me switch thicknesses mid-day. Since buying it, returns due to blemishes vanished, and word-of-mouth orders surged.

Hazel –

I personalize baby bottles with measurement scales. The cold UV engraving avoids heat that could warp plastic, keeping product safety intact. Setup wizard guides me through lens swaps, and presets for PETG were spot on. Parents appreciate durable markings that withstand dishwashers, boosting repeat business at local markets.

Carter –

We manufacture medical syringes, and clear graduation lines are critical. This system marks fine lines on polycarbonate barrels without leaving raised edges or dust. The chilled optics stay stable during long shifts. Software imports vector art and serializes batch numbers automatically, saving our team hours of manual data entry every week.

Alexis –

I work in an electronics lab, and this UV marker changed our process. It writes crisp ID codes on silicone keypads without melting edges. The beam diameter is tiny, so we fit long part numbers in tight areas. Filter fan keeps fumes away, and maintenance so far is minimal for us.

Blake –

In our cosmetics factory, we needed soft marking on plastic caps. The UV laser etches lot codes that look sharp yet never burn the surface. The open table lets operators load trays quickly, and autofocus keeps depth perfect. Since installation, rejects dropped to zero and labeling speed more than doubled.

Daphne –

I run a phone repair kiosk. Engraving tiny QR codes on tempered glass backs used to crack screens, but the cold UV beam makes flawless marks. Customers love personalized art that does not weaken the panel. The compact unit fits under my counter and plugs into a simple power strip.