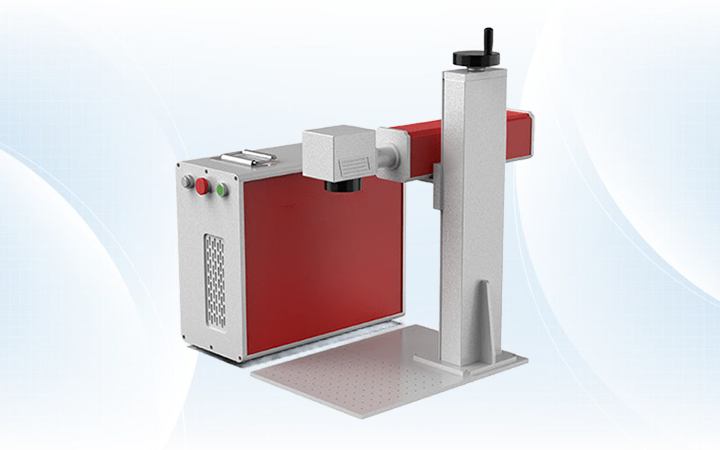

FM-FS Laser Marking Machine

The FM-FS laser marking machine features a split design, fiber laser, and high-speed galvo for precise, flexible marking on metals, plastics, and industrial components.

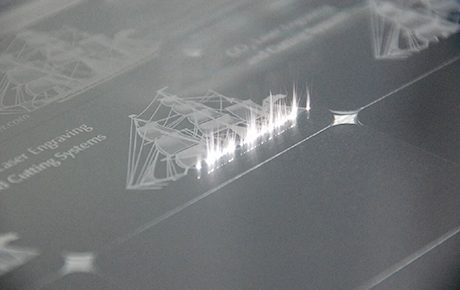

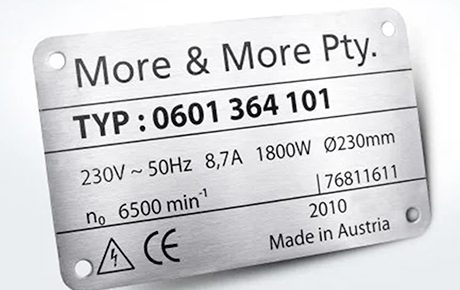

Creates sharp, high-resolution marks on metal and plastic surfaces, perfect for detailed logos, barcodes, serial numbers, and micro-text.

Marks rapidly without sacrificing quality, ideal for high-volume production lines needing fast turnaround with consistent output.

Uses a solid-state laser with up to 100,000 hours of working life, ensuring minimal downtime and long-term performance.

Consumes less power and requires no consumables or maintenance-intensive parts, significantly reducing production costs.

Marks metals, plastics, and more with excellent contrast and durability, supporting a wide range of industries and applications.

Produces marks that resist fading, abrasion, and chemicals, ensuring product traceability and brand visibility over time.

Yes, laser marking is safe when proper safety precautions are followed. Unlike laser cutting or welding, laser marking operates at lower power levels and does not produce high heat, sparks, or molten material. However, laser radiation, fumes, and reflections still pose potential risks, making protective measures essential. Potential security risks and their mitigation methods are as follows:

Laser marking is safe when operated with proper enclosures, protective eyewear, fume extraction, and workplace safety measures. Most modern fiber, CO2, MOPA, and UV laser marking machines are designed with built-in safety features, making them suitable for industrial and commercial use with minimal risk.

Laser marks are highly permanent and offer superior durability compared to traditional marking methods like ink printing, engraving, or etching. The permanence of a laser mark depends on material type, marking method, and environmental exposure, but in most cases, laser markings remain intact for a lifetime. The factors that affect the durability of laser marking are as follows:

Laser marks are one of the most permanent marking solutions, lasting years to a lifetime depending on material and usage conditions. Deep engraving, annealing, and high-contrast marking methods ensure resistance to wear, heat, chemicals, and UV exposure, making laser marking ideal for industrial, medical, aerospace, and consumer applications.

Laser marking machines support a variety of vector and raster file formats to ensure compatibility with different design software. The most commonly supported file formats include:

Laser marking machines are compatible with vector files (DXF, AI, PLT, SVG, PDF), raster images (BMP, JPG, PNG, TIFF), and CAD formats (DWG, G-Code). Vector files are recommended for precision engraving, while raster files are ideal for photographic or grayscale engraving. Always check the machine’s software for specific format support.

We offer a comprehensive warranty policy to ensure reliable performance and long-term support for our laser marking machines. Below is a detailed breakdown of our warranty coverage, including the warranty period, terms and conditions for different components, and how customers can apply for warranty service.

Our laser marking machine has a 3-year warranty on the entire machine, a 2-year warranty on the laser generator, and a 1-year warranty on core components. This structured warranty ensures that customers receive high-quality support and service. To maintain the performance of the machine and extend its life, we recommend regular maintenance and correct operation. If any problems arise, our technical support team can assist with troubleshooting and warranty claims.

Our laser marking machines meet international quality, safety, and regulatory standards, ensuring reliability, compliance, and customer confidence. Below is a detailed overview of the key certifications our machines hold and their significance.

Our laser marking machines are certified to meet international quality and safety standards, including ISO 9001, CE, and FDA certifications. These certifications ensure that our machines are manufactured with strict quality control, meet European safety regulations, and comply with U.S. laser safety requirements. Customers can be assured of high performance, reliability, and legal compliance when purchasing and operating our machines.

On-site technical support is available for laser marking machines, providing customers with hands-on assistance for installation, troubleshooting, training, and maintenance. However, this service comes at an additional cost. The standard service fee is US$200 per day, and customers are also responsible for covering the engineer’s round-trip airfare, board, lodging, and local transportation if required. This ensures that customers receive expert guidance directly at their facility to maximize machine performance and minimize downtime. The process for requesting on-site support involves contacting customer service, providing details of the issue, receiving a cost estimate, and scheduling an engineer visit. While on-site service is a valuable option, customers can also choose remote support, which includes troubleshooting via phone, email, or video calls, as well as access to online training materials and documentation at no additional cost. If in-person assistance is necessary, we are ready to arrange a visit to ensure the machine operates efficiently and reliably.

Our machines deliver ultra-fine marking and engraving with high-speed galvanometer systems and stable laser sources for consistent, reliable output.

We offer different laser types to match your needs, ensuring crisp, permanent marks on metal, plastic, wood, leather, and more.

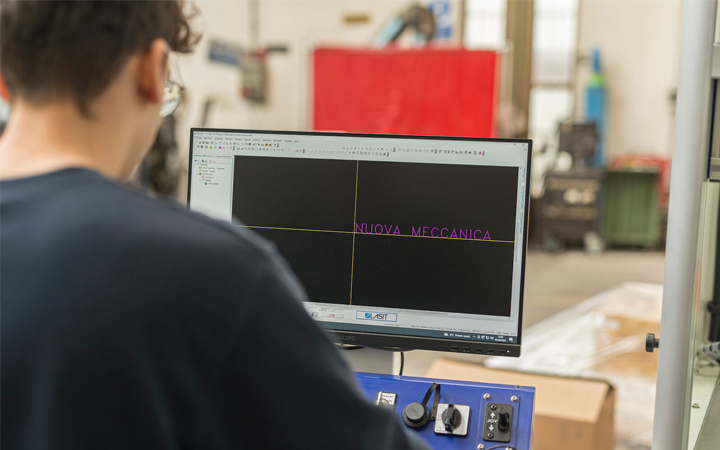

Intuitive control software allows easy setup, flexible design import, and precise marking even for first-time users.

We provide machine options tailored to your product size, line speed, and marking content for seamless integration.

Our systems run cleanly with no inks or chemicals, lowering long-term operating costs and environmental impact.

Faster Laser offers professional training, remote troubleshooting, and responsive service to keep your production running smoothly.

8 reviews for FM-FS Laser Marking Machine

Jackson –

I operate a souvenir kiosk and wanted quick metal tagging. This laser’s footprint is small enough for a mall stall, yet power is plenty for steel keychains. The red-light preview speeds customer interactions, and design import from Illustrator keeps workflow familiar. Noise level is low, so conversations aren’t drowned out while the machine runs nearby.

Ella –

Our aerospace shop needed traceable barcodes on titanium brackets. The laser handles small DataMatrix codes effortlessly, and scanners verify them on first try. Cooling fins stay barely warm during long shifts, proving good thermal design. Documentation package included a calibration certificate, which pleased our quality department. Downtime since installation: zero. That says it all.

Henry –

I use the machine for art projects, and the grayscale photo engraving mode is amazing. Portraits on stainless steel come out detailed enough to show fine hair strands. I was worried about fumes, but the optional extractor keeps the studio air fresh. Friends now ask me to personalize gifts, turning a hobby into steady weekend income.

Abigail –

This laser replaced pad printing on aluminum enclosures. Setup time dropped from hours to minutes, and marks are scratch-proof. The machine’s built-in ruler helps align parts quickly, even for odd shapes. Variable text and date codes update by themselves each morning, removing manual steps. Overall, production errors fell noticeably and operators appreciate the cleaner process.

James –

Our firearms customization shop required deep engraving for legal serials. This unit cuts through hard chrome layers without chatter, and edge walls stay squared. Rotary chuck holds barrels steady, and pulse control minimizes heat discoloration. Customers love the sharp, professional look, and we save on outsourcing fees while meeting strict regulatory guidelines with confidence.

Benjamin –

We integrate the laser into an automated cell using the provided I/O ports. Triggering over PLC was straightforward, and the galvo response time keeps pace with the robot arm. The compact chassis fits under the conveyor height, saving floor space. Maintenance alarms pop up on screen, so my team never forgets filter changes or lens cleaning.

Evelyn –

I needed durable marks on outdoor signage parts. The laser’s stainless steel marks withstand salt-spray testing with no fading. Pass-through feature lets me process long brackets, and indexing is precise. Tech support even supplied a jig drawing for odd profiles. The machine paid for itself in reduced outsourcing long before the accountant expected.

Elizabeth –

Teaching high-school robotics, I needed simple yet industrial-grade tools. Students learned to engrave team logos in an afternoon. The software’s layer colors match the design, helping visual learners. Protective cover and interlock satisfy campus safety rules. The class even engraved trophies for neighboring schools, creating a small revenue stream to fund more parts.