FM-FH Laser Marking Machine

The FM-FH laser marking machine features a portable handheld design, fiber laser, and high-speed galvo for fast, accurate marking on large or hard-to-move metal components.

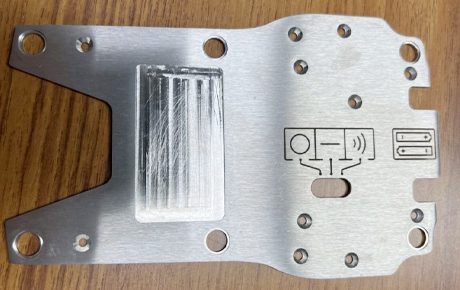

Creates sharp, high-resolution marks on metal and plastic surfaces, perfect for detailed logos, barcodes, serial numbers, and micro-text.

Marks rapidly without sacrificing quality, ideal for high-volume production lines needing fast turnaround with consistent output.

Uses a solid-state laser with up to 100,000 hours of working life, ensuring minimal downtime and long-term performance.

Consumes less power and requires no consumables or maintenance-intensive parts, significantly reducing production costs.

Marks metals, plastics, and more with excellent contrast and durability, supporting a wide range of industries and applications.

Produces marks that resist fading, abrasion, and chemicals, ensuring product traceability and brand visibility over time.

Yes, laser marking is safe when proper safety precautions are followed. Unlike laser cutting or welding, laser marking operates at lower power levels and does not produce high heat, sparks, or molten material. However, laser radiation, fumes, and reflections still pose potential risks, making protective measures essential. Potential security risks and their mitigation methods are as follows:

Laser marking is safe when operated with proper enclosures, protective eyewear, fume extraction, and workplace safety measures. Most modern fiber, CO2, MOPA, and UV laser marking machines are designed with built-in safety features, making them suitable for industrial and commercial use with minimal risk.

Laser marks are highly permanent and offer superior durability compared to traditional marking methods like ink printing, engraving, or etching. The permanence of a laser mark depends on material type, marking method, and environmental exposure, but in most cases, laser markings remain intact for a lifetime. The factors that affect the durability of laser marking are as follows:

Laser marks are one of the most permanent marking solutions, lasting years to a lifetime depending on material and usage conditions. Deep engraving, annealing, and high-contrast marking methods ensure resistance to wear, heat, chemicals, and UV exposure, making laser marking ideal for industrial, medical, aerospace, and consumer applications.

Laser marking machines support a variety of vector and raster file formats to ensure compatibility with different design software. The most commonly supported file formats include:

Laser marking machines are compatible with vector files (DXF, AI, PLT, SVG, PDF), raster images (BMP, JPG, PNG, TIFF), and CAD formats (DWG, G-Code). Vector files are recommended for precision engraving, while raster files are ideal for photographic or grayscale engraving. Always check the machine’s software for specific format support.

We offer a comprehensive warranty policy to ensure reliable performance and long-term support for our laser marking machines. Below is a detailed breakdown of our warranty coverage, including the warranty period, terms and conditions for different components, and how customers can apply for warranty service.

Our laser marking machine has a 3-year warranty on the entire machine, a 2-year warranty on the laser generator, and a 1-year warranty on core components. This structured warranty ensures that customers receive high-quality support and service. To maintain the performance of the machine and extend its life, we recommend regular maintenance and correct operation. If any problems arise, our technical support team can assist with troubleshooting and warranty claims.

Our laser marking machines meet international quality, safety, and regulatory standards, ensuring reliability, compliance, and customer confidence. Below is a detailed overview of the key certifications our machines hold and their significance.

Our laser marking machines are certified to meet international quality and safety standards, including ISO 9001, CE, and FDA certifications. These certifications ensure that our machines are manufactured with strict quality control, meet European safety regulations, and comply with U.S. laser safety requirements. Customers can be assured of high performance, reliability, and legal compliance when purchasing and operating our machines.

On-site technical support is available for laser marking machines, providing customers with hands-on assistance for installation, troubleshooting, training, and maintenance. However, this service comes at an additional cost. The standard service fee is US$200 per day, and customers are also responsible for covering the engineer’s round-trip airfare, board, lodging, and local transportation if required. This ensures that customers receive expert guidance directly at their facility to maximize machine performance and minimize downtime. The process for requesting on-site support involves contacting customer service, providing details of the issue, receiving a cost estimate, and scheduling an engineer visit. While on-site service is a valuable option, customers can also choose remote support, which includes troubleshooting via phone, email, or video calls, as well as access to online training materials and documentation at no additional cost. If in-person assistance is necessary, we are ready to arrange a visit to ensure the machine operates efficiently and reliably.

Our machines deliver ultra-fine marking and engraving with high-speed galvanometer systems and stable laser sources for consistent, reliable output.

We offer different laser types to match your needs, ensuring crisp, permanent marks on metal, plastic, wood, leather, and more.

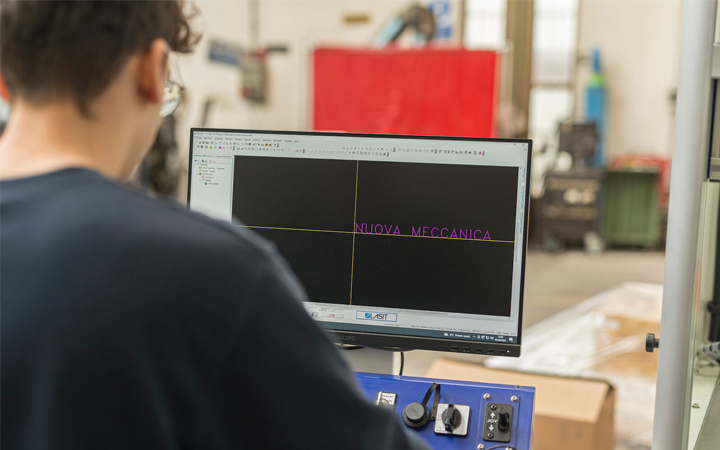

Intuitive control software allows easy setup, flexible design import, and precise marking even for first-time users.

We provide machine options tailored to your product size, line speed, and marking content for seamless integration.

Our systems run cleanly with no inks or chemicals, lowering long-term operating costs and environmental impact.

Faster Laser offers professional training, remote troubleshooting, and responsive service to keep your production running smoothly.

8 reviews for FM-FH Laser Marking Machine

Amelia –

I switched from chemical etching to this laser for bicycle components. Cleanup is now minimal, and edge definition is sharper. The pass-through slot accommodates long seat posts, eliminating jig changes. Batch serialization is automated, so I simply feed the parts. Even after hundreds of units, engraved text remains uniform. Environmental compliance audits were easier without chemical solvents.

Charlotte –

I replaced a dated YAG system with this fiber model and noticed immediate gains. Marking stainless steel is faster, and the beam is stable from first pulse. The rotary chuck’s jaw design prevents marring polished pieces, handy for luxury pens. A single pass leaves crisp edges that need no post-polish, cutting production steps and boosting overall throughput.

Logan –

After two weeks with the new fiber unit, I’m genuinely impressed. The rotary attachment grips tumblers firmly and keeps artwork perfectly aligned. The machine engraves stainless, brass, and coated aluminum with equal precision, and the compact footprint fits nicely on my small workshop bench. Continuous operation for eight hours shows no sign of power loss at all.

Lucas –

Looking for low-maintenance marking, I decided to upgrade our equipment. The laser’s sealed fiber source promises a long life, and there’s no messy coolant to check. I engraved one thousand serial plates last week without a single reject. The machine’s power meter matches my external sensor within one percent, which tells me calibration from the factory was spot-on.

Mason –

Our engineering school uses this marker for student projects. Freshmen pick it up fast because the interface resembles common design software. Safety interlocks shut the beam if the cover lifts, easing faculty concerns. Despite daily use by beginners, alignment is still dead-on after a semester. It’s become the go-to machine for rapid prototyping metal housings.

Mia –

I bought the unit for jewelry branding and couldn’t be happier. It cleanly ablates gold without rough edges, and depth control is accurate enough for delicate pendants. The included fume extractor handles fine particles well, leaving stones spotless. After adding QR codes to bracelets, my online store saw fewer returns because customers appreciate the professional authenticity marks.

Harper –

I was hesitant about the learning curve, but the bundled tutorials walk through every step. Within a day I was marking anodized phone cases with perfect contrast. The machine’s red-light preview aligns graphics exactly where I want them, reducing scrap. Weekly maintenance amounts to wiping optics and checking lens screws—simple tasks I can fit into coffee breaks.

Ethan –

As a contract fabricator, flexibility is key. This laser’s quick lens swap lets me jump from small tags to full-size panels. Software libraries store presets, so I can recall ideal settings instantly. The air-cooled design lowers shop power demand, saving costs. Clients who visited were impressed by the clean marking and fast cycle times.