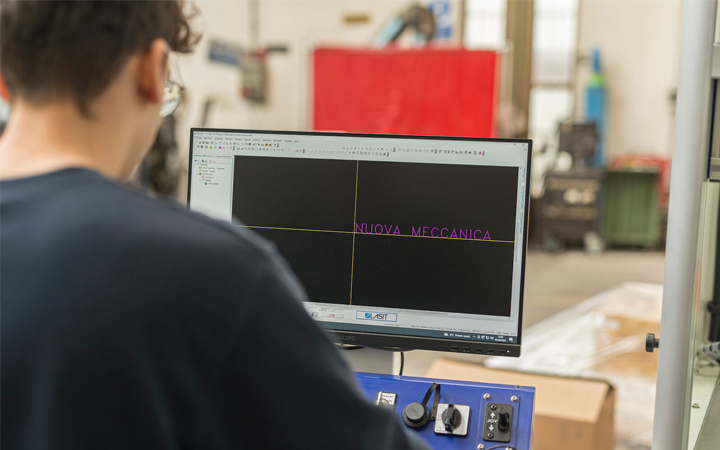

FM-FD Laser Marking Machine

The FM-FD laser marking machine features a compact desktop design, fiber laser, high-speed galvo, and red dot pointer for fast, precise, and durable engraving on various materials.

Creates sharp, high-resolution marks on metal and plastic surfaces, perfect for detailed logos, barcodes, serial numbers, and micro-text.

Marks rapidly without sacrificing quality, ideal for high-volume production lines needing fast turnaround with consistent output.

Uses a solid-state laser with up to 100,000 hours of working life, ensuring minimal downtime and long-term performance.

Consumes less power and requires no consumables or maintenance-intensive parts, significantly reducing production costs.

Marks metals, plastics, and more with excellent contrast and durability, supporting a wide range of industries and applications.

Produces marks that resist fading, abrasion, and chemicals, ensuring product traceability and brand visibility over time.

Yes, laser marking is safe when proper safety precautions are followed. Unlike laser cutting or welding, laser marking operates at lower power levels and does not produce high heat, sparks, or molten material. However, laser radiation, fumes, and reflections still pose potential risks, making protective measures essential. Potential security risks and their mitigation methods are as follows:

Laser marking is safe when operated with proper enclosures, protective eyewear, fume extraction, and workplace safety measures. Most modern fiber, CO2, MOPA, and UV laser marking machines are designed with built-in safety features, making them suitable for industrial and commercial use with minimal risk.

Laser marks are highly permanent and offer superior durability compared to traditional marking methods like ink printing, engraving, or etching. The permanence of a laser mark depends on material type, marking method, and environmental exposure, but in most cases, laser markings remain intact for a lifetime. The factors that affect the durability of laser marking are as follows:

Laser marks are one of the most permanent marking solutions, lasting years to a lifetime depending on material and usage conditions. Deep engraving, annealing, and high-contrast marking methods ensure resistance to wear, heat, chemicals, and UV exposure, making laser marking ideal for industrial, medical, aerospace, and consumer applications.

Laser marking machines support a variety of vector and raster file formats to ensure compatibility with different design software. The most commonly supported file formats include:

Laser marking machines are compatible with vector files (DXF, AI, PLT, SVG, PDF), raster images (BMP, JPG, PNG, TIFF), and CAD formats (DWG, G-Code). Vector files are recommended for precision engraving, while raster files are ideal for photographic or grayscale engraving. Always check the machine’s software for specific format support.

We offer a comprehensive warranty policy to ensure reliable performance and long-term support for our laser marking machines. Below is a detailed breakdown of our warranty coverage, including the warranty period, terms and conditions for different components, and how customers can apply for warranty service.

Our laser marking machine has a 3-year warranty on the entire machine, a 2-year warranty on the laser generator, and a 1-year warranty on core components. This structured warranty ensures that customers receive high-quality support and service. To maintain the performance of the machine and extend its life, we recommend regular maintenance and correct operation. If any problems arise, our technical support team can assist with troubleshooting and warranty claims.

Our laser marking machines meet international quality, safety, and regulatory standards, ensuring reliability, compliance, and customer confidence. Below is a detailed overview of the key certifications our machines hold and their significance.

Our laser marking machines are certified to meet international quality and safety standards, including ISO 9001, CE, and FDA certifications. These certifications ensure that our machines are manufactured with strict quality control, meet European safety regulations, and comply with U.S. laser safety requirements. Customers can be assured of high performance, reliability, and legal compliance when purchasing and operating our machines.

On-site technical support is available for laser marking machines, providing customers with hands-on assistance for installation, troubleshooting, training, and maintenance. However, this service comes at an additional cost. The standard service fee is US$200 per day, and customers are also responsible for covering the engineer’s round-trip airfare, board, lodging, and local transportation if required. This ensures that customers receive expert guidance directly at their facility to maximize machine performance and minimize downtime. The process for requesting on-site support involves contacting customer service, providing details of the issue, receiving a cost estimate, and scheduling an engineer visit. While on-site service is a valuable option, customers can also choose remote support, which includes troubleshooting via phone, email, or video calls, as well as access to online training materials and documentation at no additional cost. If in-person assistance is necessary, we are ready to arrange a visit to ensure the machine operates efficiently and reliably.

Our machines deliver ultra-fine marking and engraving with high-speed galvanometer systems and stable laser sources for consistent, reliable output.

We offer different laser types to match your needs, ensuring crisp, permanent marks on metal, plastic, wood, leather, and more.

Intuitive control software allows easy setup, flexible design import, and precise marking even for first-time users.

We provide machine options tailored to your product size, line speed, and marking content for seamless integration.

Our systems run cleanly with no inks or chemicals, lowering long-term operating costs and environmental impact.

Faster Laser offers professional training, remote troubleshooting, and responsive service to keep your production running smoothly.

8 reviews for FM-FD Laser Marking Machine

Emma –

I bought this fiber marker four months ago for my engraving studio. Marking speed exceeds my previous CO₂ unit by a big margin, and the compact footprint fits nicely on my small bench. The machine engraves stainless, brass, and coated aluminum with equal precision. Customer service answered my alignment question within thirty minutes by chat, which really boosted confidence.

Elijah –

I needed tiny yet legible serials on medical parts, and this laser delivered. Lines stay sharp even at six-point font, and the software’s variable text tool inserts batch data automatically. Air-cooled galvo never overheats, so shifts run uninterrupted. After two months, the unit hasn’t missed a beat, and regulators praised the readability of the finished components.

Sophia –

As a hobbyist turning gifts into a side hustle, this tool is the centerpiece. The compact design leaves room for other equipment, yet the power tops out stainless steel in one pass. Rotary attachment keeps champagne flutes centered, producing crisp wrap-around artwork. Support videos cover everything from focus tricks to deep engraving, making the learning curve smooth and encouraging.

Oliver –

I was cautious about switching from ink-jet coding, but this machine impressed me right away. Set up was straightforward thanks to the clear manual and quick-start videos. The rotary attachment grips tumblers firmly and keeps artwork perfectly aligned. Continuous operation for eight hours shows no sign of power loss, and engraved barcodes scan flawlessly every time.

Noah –

Our production line required clear, permanent marks, so we added this unit. Pass-through slot lets me handle long stainless steel rulers without extra fixtures, and the foot pedal trigger is handy for batch nameplates. Firmware updates are delivered by email and install quickly. After three weeks, reject rates on serialized panels dropped to zero, saving both time and materials.

Liam –

I’ve run this laser daily since it arrived and wanted to share thoughts. The EZCAD software is flexible, letting me import DXF and SVG files effortlessly. The red-dot focus tool saves time when switching between material heights, and air cooling keeps maintenance simple. Power stability test showed less than one percent drift over a full shift, which is outstanding.

Isabella –

My custom knife business relies on crisp logos, so precision mattered most. This marker lays down deep, even marks on hardened steel without discoloration. Switching to a 110 mm lens keeps larger blades entirely in field. The red-light preview prevents misalignment, saving expensive blanks. Compared with outsourcing, my turnaround time dropped dramatically, and clients notice the professional finish.

Ava –

Running a small metal shop, I needed a reliable marker and took the plunge. The machine ships with a good assortment of lenses for different field sizes, so I can mark tiny serials or large logos without fuss. Fine adjustment of pulse frequency helps achieve high-contrast marks on anodized parts, and the low noise level keeps my workspace pleasant.