FM-CD Laser Marking Machine

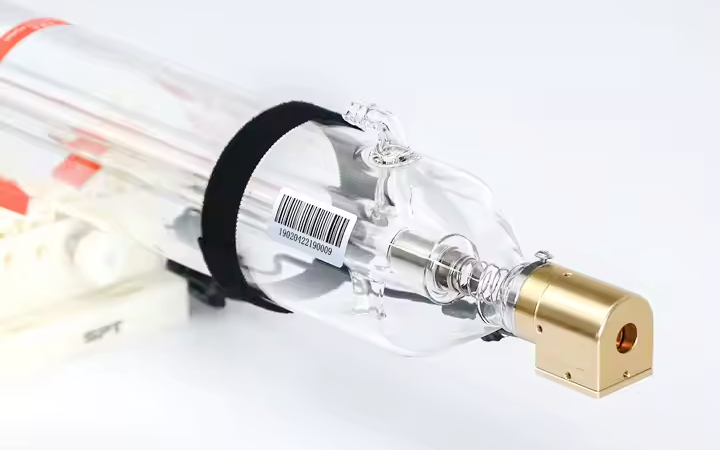

The FM-CD laser marking machine features a desktop design and CO2 laser for fast, precise marking on wood, acrylic, leather, and other non-metal materials.

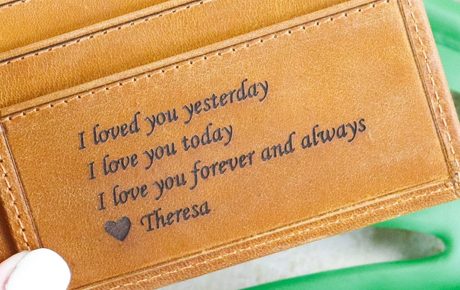

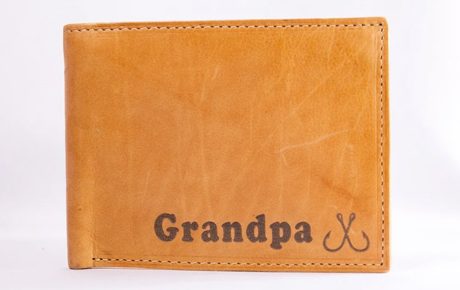

Specializes in marking wood, glass, acrylic, leather, paper, and plastics with high clarity and minimal surface damage.

Delivers smooth, precise, and detailed marks with excellent contrast, ideal for decorative patterns, logos, and fine-texturing.

Offers reliable performance at a lower upfront cost, making it a budget-friendly choice for businesses needing marking on non-metals.

Available with wide working fields to accommodate bigger objects or batch processing without frequent repositioning.

Eliminates mechanical stress on materials, preserving product integrity and reducing wear compared to traditional engraving or printing.

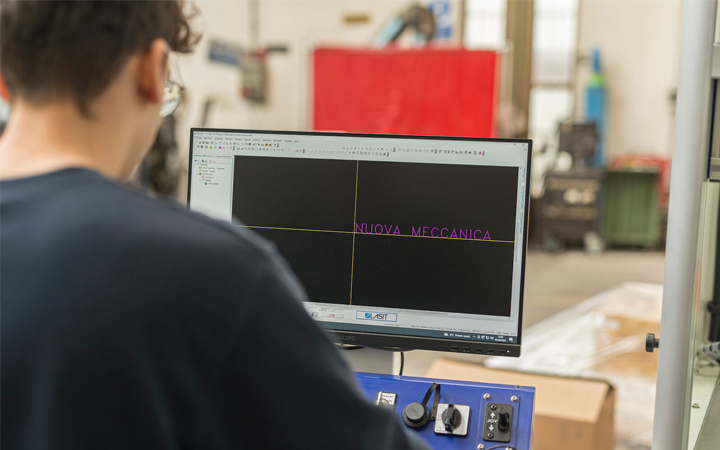

User-friendly software and simple system design make it easy to run, with minimal maintenance and low training requirements.

Yes, laser marking is safe when proper safety precautions are followed. Unlike laser cutting or welding, laser marking operates at lower power levels and does not produce high heat, sparks, or molten material. However, laser radiation, fumes, and reflections still pose potential risks, making protective measures essential. Potential security risks and their mitigation methods are as follows:

Laser marking is safe when operated with proper enclosures, protective eyewear, fume extraction, and workplace safety measures. Most modern fiber, CO2, MOPA, and UV laser marking machines are designed with built-in safety features, making them suitable for industrial and commercial use with minimal risk.

Laser marks are highly permanent and offer superior durability compared to traditional marking methods like ink printing, engraving, or etching. The permanence of a laser mark depends on material type, marking method, and environmental exposure, but in most cases, laser markings remain intact for a lifetime. The factors that affect the durability of laser marking are as follows:

Laser marks are one of the most permanent marking solutions, lasting years to a lifetime depending on material and usage conditions. Deep engraving, annealing, and high-contrast marking methods ensure resistance to wear, heat, chemicals, and UV exposure, making laser marking ideal for industrial, medical, aerospace, and consumer applications.

Laser marking machines support a variety of vector and raster file formats to ensure compatibility with different design software. The most commonly supported file formats include:

Laser marking machines are compatible with vector files (DXF, AI, PLT, SVG, PDF), raster images (BMP, JPG, PNG, TIFF), and CAD formats (DWG, G-Code). Vector files are recommended for precision engraving, while raster files are ideal for photographic or grayscale engraving. Always check the machine’s software for specific format support.

We offer a comprehensive warranty policy to ensure reliable performance and long-term support for our laser marking machines. Below is a detailed breakdown of our warranty coverage, including the warranty period, terms and conditions for different components, and how customers can apply for warranty service.

Our laser marking machine has a 3-year warranty on the entire machine, a 2-year warranty on the laser generator, and a 1-year warranty on core components. This structured warranty ensures that customers receive high-quality support and service. To maintain the performance of the machine and extend its life, we recommend regular maintenance and correct operation. If any problems arise, our technical support team can assist with troubleshooting and warranty claims.

Our laser marking machines meet international quality, safety, and regulatory standards, ensuring reliability, compliance, and customer confidence. Below is a detailed overview of the key certifications our machines hold and their significance.

Our laser marking machines are certified to meet international quality and safety standards, including ISO 9001, CE, and FDA certifications. These certifications ensure that our machines are manufactured with strict quality control, meet European safety regulations, and comply with U.S. laser safety requirements. Customers can be assured of high performance, reliability, and legal compliance when purchasing and operating our machines.

On-site technical support is available for laser marking machines, providing customers with hands-on assistance for installation, troubleshooting, training, and maintenance. However, this service comes at an additional cost. The standard service fee is US$200 per day, and customers are also responsible for covering the engineer’s round-trip airfare, board, lodging, and local transportation if required. This ensures that customers receive expert guidance directly at their facility to maximize machine performance and minimize downtime. The process for requesting on-site support involves contacting customer service, providing details of the issue, receiving a cost estimate, and scheduling an engineer visit. While on-site service is a valuable option, customers can also choose remote support, which includes troubleshooting via phone, email, or video calls, as well as access to online training materials and documentation at no additional cost. If in-person assistance is necessary, we are ready to arrange a visit to ensure the machine operates efficiently and reliably.

Our machines deliver ultra-fine marking and engraving with high-speed galvanometer systems and stable laser sources for consistent, reliable output.

We offer different laser types to match your needs, ensuring crisp, permanent marks on metal, plastic, wood, leather, and more.

Intuitive control software allows easy setup, flexible design import, and precise marking even for first-time users.

We provide machine options tailored to your product size, line speed, and marking content for seamless integration.

Our systems run cleanly with no inks or chemicals, lowering long-term operating costs and environmental impact.

Faster Laser offers professional training, remote troubleshooting, and responsive service to keep your production running smoothly.

8 reviews for FM-CD Laser Marking Machine

Felicity –

Lens cleaning kit comes included, making routine maintenance straightforward. Fans run quietly, so conversations continue while the machine operates. Software imports vector files directly from Illustrator, avoiding double conversion work. Preview outline projects entire design, reassuring customers during live demonstrations. Honeycomb bed prevents backflash, keeping the reverse side blemish-free.

Celeste –

Autofocus sensor compensates for minor warps in plywood sheets flawlessly. Preview outline projects entire design, reassuring customers during live demonstrations. Fans run quietly, so conversations continue while the machine operates. Cooling alarm has never triggered, proving solid thermal design. Exhaust fan and charcoal filter remove smoke smells from our tiny shop.

Ronan –

Exhaust fan and charcoal filter remove smoke smells from our tiny shop. Pass-through slot lets us handle metre-long panels without pausing the job. Technical support answers emails within an hour, even on weekends. Focus probe clicks firmly, making height changes quick between material swaps. Honeycomb bed prevents backflash, keeping the reverse side blemish-free.

Marcus –

Pass-through slot lets us handle metre-long panels without pausing the job. Exhaust fan and charcoal filter remove smoke smells from our tiny shop. Water chiller maintains stable temperature even during back-to-back production runs. Barcode generator adds variable data automatically, cutting manual typing errors. Power supply shows consistent output; our oscilloscope recorded minimal fluctuation.

Giselle –

Rotary chuck grips bottles securely and leaves no scuffs on glass. Water chiller maintains stable temperature even during back-to-back production runs. Fine raster mode engraves greyscale photographs on coated wood impressively. Template library stores favorite settings, speeding changeovers between different thicknesses. Barcode generator adds variable data automatically, cutting manual typing errors.

Bianca –

Safety lid interlock satisfies our insurance requirements for classroom use. Setup took less than an hour and required only basic tools. Focus probe clicks firmly, making height changes quick between material swaps. QR codes generated by the software scan first time, every time. Cooling alarm has never triggered, proving solid thermal design.

Simon –

We engrave wood, acrylic, and leather daily without adjusting factory presets. Air assist keeps edges clean, reducing post-processing on delicate pieces. Firmware updates install via USB stick in under two minutes. Operators appreciate the color touchscreen with intuitive icons. Job history log exports to CSV, simplifying cost tracking for quotes.

Theo –

Template library stores favorite settings, speeding changeovers between different thicknesses. Job history log exports to CSV, simplifying cost tracking for quotes. Laser beam leaves polished acrylic edges, eliminating hand flame polishing. Rotatory chuck grips bottles securely and leaves no scuffs on glass. Technical support answers emails within an hour, even on weekends.