FE Laser Cutting Machine

The FE laser cutting machine delivers high-speed, precision cutting with an advanced fiber laser, a double-worktable design, and user-friendly controls for maximum efficiency.

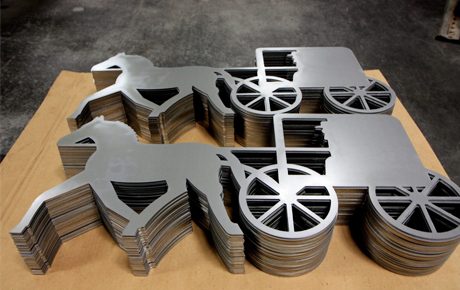

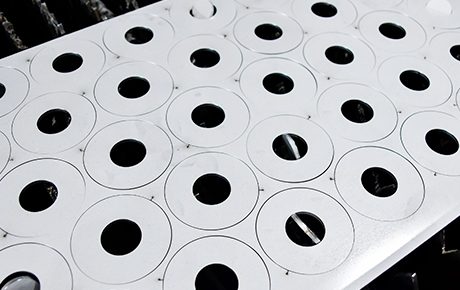

Providing ultra-fine cuts with minimal deviation, enabling the fabrication of complex shapes, intricate patterns, and delicate metals.

Operates at significantly higher speeds than CO2 lasers, boosting production efficiency and reducing turnaround time for orders.

They consume less electricity and require minimal maintenance, thus reducing long-term production costs.

Handles a wide range of metals—stainless steel, carbon steel, aluminum, brass—with consistent quality across varying thicknesses.

Built with robust components for long-term operation under tough conditions, minimizing downtime and maximizing productivity.

Producing fewer emissions, cleaner edges, and environmentally responsible manufacturing without compromising quality.

| Model | FE3015 | FE4015 | FE4020 | FE6015 | FE6025 |

| Cutting Range | 3000*1500mm | 4500*1500mm | 4000*2000mm | 6000*1500mm | 6000*2500mm |

| Laser Type | Fiber Laser | ||||

| Laser Power | 1500-12000W | ||||

| Laser Generator | Raycus/Max/IPG | ||||

| Laser Cutting Head | Raytools | ||||

| Servo Motor And Driver | Delta | ||||

| Servo Motor Power | 1500W-3000W: XY=850W, Z=400W; 6000W: XY=850/1300W, Z=400W; 12000W: XY=1300/1800W, Z=400W; |

||||

| Guide Rails | Taiwan Linear Rails | ||||

| X, Y-Axis Rack | Deutschland | ||||

| X, Y-Axis Gear | Germany Atlanta | ||||

| X, Y-Axis Reducer | Shinpo/Motoreducer | ||||

| Max Acceleration | 0.8/0.9G | ||||

| Max Linkage Speed | 70/130m/min | ||||

| Z-Axis Travel | 100mm | ||||

| Positioning Accuracy | 0.05mm | ||||

| Repositioning Accuracy | 0.03mm | ||||

| Control System | FSCUT | ||||

The lead time for our fiber laser cutting machine is typically 30 to 40 working days, covering the entire process from order confirmation to shipment. This timeframe ensures that every machine undergoes thorough manufacturing, assembly, and quality control before delivery. The production process begins with order confirmation, where design specifications and technical requirements are finalized. Standard models generally follow the expected lead time, while customized configurations may take longer due to additional engineering and component sourcing.

While the standard lead time remains within 30 to 40 working days, several factors can affect the actual delivery schedule. Custom orders with special features or additional accessories may require extended production time. Additionally, the availability of specific components and the overall factory workload can influence manufacturing speed. Bulk orders may take slightly longer due to increased quality control measures. External factors such as supply chain disruptions or peak production periods can also play a role. Once the machine is ready for dispatch, shipping duration depends on the chosen transportation method and the destination.

For those needing an expedited process, we recommend confirming orders early to secure a production slot, selecting standard models with minimal customization, and working closely with our team to explore the fastest shipping options. By following these steps, we can help reduce delays and ensure a smooth and timely delivery.

Selecting the best laser cutting machine depends on several factors, including the type of materials you work with, required precision, production volume, and budget.

Selecting the best laser cutting machine depends on multiple factors, including material type, thickness, size, accuracy needs, production volume, budget, and automation features. For cutting metals, fiber lasers provide the best efficiency, while CO2 lasers are better suited for non-metal applications. A well-chosen laser cutter ensures optimal performance, cost-effectiveness, and long-term reliability based on your specific manufacturing needs.

Laser cutting machines are widely used for precision cutting in industries such as metal fabrication, automotive, and electronics. To ensure seamless operation, these machines support a range of file formats that cater to different design software and user requirements.

The compatibility of laser cutting machines with multiple file formats makes them adaptable for various industries, from industrial manufacturing to artistic design. Choosing the right file format ensures precise cuts, minimal errors, and high-quality output. For the best results, always use vector-based files such as DXF, AI, and DWG, as they maintain design accuracy and allow smooth cutting operations.

We offer a comprehensive warranty policy to ensure reliable performance and long-term support for our laser cutting machines. Below is a detailed breakdown of our warranty coverage, including the warranty period, terms and conditions for different components, and how customers can apply for warranty service.

Our laser cutting machine has a 3-year warranty on the entire machine, a 2-year warranty on the laser generator, and a 1-year warranty on core components. This structured warranty ensures that customers receive high-quality support and service. To maintain the performance of the machine and extend its life, we recommend regular maintenance and correct operation. If any problems arise, our technical support team can assist with troubleshooting and warranty claims.

Our laser cutting machines meet international quality, safety, and regulatory standards, ensuring reliability, compliance, and customer confidence. Below is a detailed overview of the key certifications our machines hold and their significance.

Our laser cutting machines are certified to meet international quality and safety standards, including ISO 9001, CE, and FDA certifications. These certifications ensure that our machines are manufactured with strict quality control, meet European safety regulations, and comply with U.S. laser safety requirements. Customers can be assured of high performance, reliability, and legal compliance when purchasing and operating our machines.

On-site technical support is available for laser cutting machines, providing customers with hands-on assistance for installation, troubleshooting, training, and maintenance. However, this service comes at an additional cost. The standard service fee is US$200 per day, and customers are also responsible for covering the engineer’s round-trip airfare, board, lodging, and local transportation if required. This ensures that customers receive expert guidance directly at their facility to maximize machine performance and minimize downtime. The process for requesting on-site support involves contacting customer service, providing details of the issue, receiving a cost estimate, and scheduling an engineer visit. While on-site service is a valuable option, customers can also choose remote support, which includes troubleshooting via phone, email, or video calls, as well as access to online training materials and documentation at no additional cost. If in-person assistance is necessary, we are ready to arrange a visit to ensure the machine operates efficiently and reliably.

Every Faster Laser machine is built with the latest advancements, ensuring precise cuts, faster operation speeds, and the ability to handle complex designs effortlessly.

We use only premium-grade materials and components, ensuring that every machine delivers consistent performance and maintains durability under heavy use.

Our team works closely with each customer to develop tailored laser cutting solutions that meet specific production needs and business objectives.

Faster Laser provides thorough training, responsive technical support, and ongoing maintenance services to keep your machines running at peak efficiency.

We offer high-quality laser cutting machines at competitive prices, ensuring you get maximum performance and long-term value from your investment.

With years of expertise and a strong global client base, Faster Laser has built a reputation for reliability, innovation, and customer satisfaction.

8 reviews for FE Laser Cutting Machine

Trevor –

Grind time before TIG welding dropped dramatically because laser-cut edges arrive smooth and oxide-free. Butt joints align without gaps, and penetration remains consistent. Toolpath simulation identifies potential fixture clashes early. Weld reject rates fell below one percent, boosting throughput and reducing operator fatigue on long shifts.

Megan –

My company produces custom kitchen fixtures, and clients demand perfect stainless edges. The laser cuts brushed sheets without marring the surface film. Switching to a thicker plate only requires loading a different profile. I like that the software suggests pierce strategy based on hole size, minimizing heat discoloration.

Thomas –

We used to lose time grinding edges before TIG welding. Now laser-cut blanks fit perfectly, slashing prep time. Butt joints align without gaps, and weld penetration is consistent. Toolpath simulation shows potential clashes, which helps us pre-plan fixtures. Reject rates for welded frames dropped sharply.

Chloe –

The laser’s narrow heat-affected zone prevents warping on delicate copper heat sinks. Built-in autofocus senses height variances on warped sheets and adjusts on the fly. The machine logs environmental data, so we can trace any anomaly. Customer service guided us through customs paperwork during import with zero hassles.

Charles –

I was skeptical about calibration, but the auto-focus routine checks focal length each shift and logs results. The motion system uses absolute encoders, so no homing crashes. Spare parts are stocked regionally, and the supplier can remote-diagnose by secure link, saving travel costs. Training videos are short and clear.

Hannah –

Cycle time dashboards help me spot bottlenecks in real time. Cloud reports show idle minutes, letting us tweak job sequencing. Since installing the laser, overall plant throughput rose 28 percent. The energy meter integrates with our sustainability goals, documenting reduced carbon output for annual CSR reports.

Joseph –

We previously outsourced aluminum cutting, adding costly freight delays. Bringing the work in-house with this laser reduced lead time from two weeks to two days and lowered part costs by 35 percent. Operators praise the ergonomic console and low noise level. Year-end customer audits highlighted our improved responsiveness.

Serena –

The narrow heat-affected zone prevents warping on delicate copper heat sinks. Built-in autofocus senses height variance mid-cut and adjusts instantly. Environmental logging attaches to every job, ensuring traceability during product validation. The cutter helped shorten prototype cycles by weeks, accelerating our go-to-market schedule in a highly competitive sector for critical telecom hardware.