FC-D Laser Cutting Machine

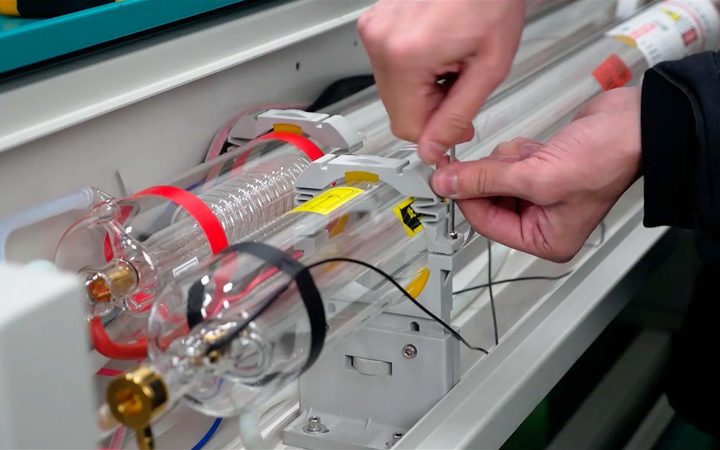

The FC-D laser cutting machine features a safety-enclosed bed, an electric lifting table, and a high-efficiency CO2 laser for precise, versatile, and safe non-metal material processing.

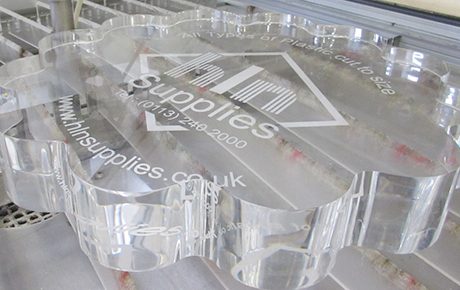

Excels at cutting wood, acrylic, plastic, leather, and textiles with clean edges and minimal post-processing required.

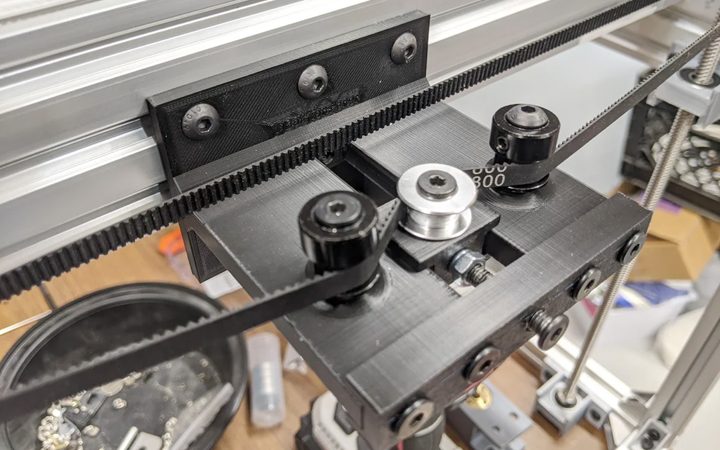

Delivers a consistent and stable laser beam, ensuring precise and clean cuts across various material types and surface finishes.

Offers reliable performance at a lower upfront cost, making it ideal for small to mid-scale production and workshops.

Accommodates large-format materials easily, enabling users to process bigger sheets without frequent repositioning.

Operates quietly with minimal mechanical vibration, enhancing user comfort and reducing wear on internal components over time.

The user-friendly interface and simple maintenance requirements make it easy to learn and keep in top working condition.

The lead time for our fiber laser cutting machine is typically 30 to 40 working days, covering the entire process from order confirmation to shipment. This timeframe ensures that every machine undergoes thorough manufacturing, assembly, and quality control before delivery. The production process begins with order confirmation, where design specifications and technical requirements are finalized. Standard models generally follow the expected lead time, while customized configurations may take longer due to additional engineering and component sourcing.

While the standard lead time remains within 30 to 40 working days, several factors can affect the actual delivery schedule. Custom orders with special features or additional accessories may require extended production time. Additionally, the availability of specific components and the overall factory workload can influence manufacturing speed. Bulk orders may take slightly longer due to increased quality control measures. External factors such as supply chain disruptions or peak production periods can also play a role. Once the machine is ready for dispatch, shipping duration depends on the chosen transportation method and the destination.

For those needing an expedited process, we recommend confirming orders early to secure a production slot, selecting standard models with minimal customization, and working closely with our team to explore the fastest shipping options. By following these steps, we can help reduce delays and ensure a smooth and timely delivery.

Selecting the best laser cutting machine depends on several factors, including the type of materials you work with, required precision, production volume, and budget.

Selecting the best laser cutting machine depends on multiple factors, including material type, thickness, size, accuracy needs, production volume, budget, and automation features. For cutting metals, fiber lasers provide the best efficiency, while CO2 lasers are better suited for non-metal applications. A well-chosen laser cutter ensures optimal performance, cost-effectiveness, and long-term reliability based on your specific manufacturing needs.

Laser cutting machines are widely used for precision cutting in industries such as metal fabrication, automotive, and electronics. To ensure seamless operation, these machines support a range of file formats that cater to different design software and user requirements.

The compatibility of laser cutting machines with multiple file formats makes them adaptable for various industries, from industrial manufacturing to artistic design. Choosing the right file format ensures precise cuts, minimal errors, and high-quality output. For the best results, always use vector-based files such as DXF, AI, and DWG, as they maintain design accuracy and allow smooth cutting operations.

We offer a comprehensive warranty policy to ensure reliable performance and long-term support for our laser cutting machines. Below is a detailed breakdown of our warranty coverage, including the warranty period, terms and conditions for different components, and how customers can apply for warranty service.

Our laser cutting machine has a 3-year warranty on the entire machine, a 2-year warranty on the laser generator, and a 1-year warranty on core components. This structured warranty ensures that customers receive high-quality support and service. To maintain the performance of the machine and extend its life, we recommend regular maintenance and correct operation. If any problems arise, our technical support team can assist with troubleshooting and warranty claims.

Our laser cutting machines meet international quality, safety, and regulatory standards, ensuring reliability, compliance, and customer confidence. Below is a detailed overview of the key certifications our machines hold and their significance.

Our laser cutting machines are certified to meet international quality and safety standards, including ISO 9001, CE, and FDA certifications. These certifications ensure that our machines are manufactured with strict quality control, meet European safety regulations, and comply with U.S. laser safety requirements. Customers can be assured of high performance, reliability, and legal compliance when purchasing and operating our machines.

On-site technical support is available for laser cutting machines, providing customers with hands-on assistance for installation, troubleshooting, training, and maintenance. However, this service comes at an additional cost. The standard service fee is US$200 per day, and customers are also responsible for covering the engineer’s round-trip airfare, board, lodging, and local transportation if required. This ensures that customers receive expert guidance directly at their facility to maximize machine performance and minimize downtime. The process for requesting on-site support involves contacting customer service, providing details of the issue, receiving a cost estimate, and scheduling an engineer visit. While on-site service is a valuable option, customers can also choose remote support, which includes troubleshooting via phone, email, or video calls, as well as access to online training materials and documentation at no additional cost. If in-person assistance is necessary, we are ready to arrange a visit to ensure the machine operates efficiently and reliably.

Every Faster Laser machine is built with the latest advancements, ensuring precise cuts, faster operation speeds, and the ability to handle complex designs effortlessly.

We use only premium-grade materials and components, ensuring that every machine delivers consistent performance and maintains durability under heavy use.

Our team works closely with each customer to develop tailored laser cutting solutions that meet specific production needs and business objectives.

Faster Laser provides thorough training, responsive technical support, and ongoing maintenance services to keep your machines running at peak efficiency.

We offer high-quality laser cutting machines at competitive prices, ensuring you get maximum performance and long-term value from your investment.

With years of expertise and a strong global client base, Faster Laser has built a reputation for reliability, innovation, and customer satisfaction.

8 reviews for FC-D Laser Cutting Machine

Perrin –

I swap between glitter acrylic and frosted PETG all day. Preset library maintains sharp edges on both, sparing manual tweaks. The machine’s quiet hum lets store design staff chat while components run. Capture camera snaps of finished nests for inventory, expediting shipping documentation.

Nova –

We cut pearl-white cardboard sleeves with curved score lines that fold neatly. Vacuum table pins stock flat, preventing skew. Lens fog sensor pauses jobs automatically, saving miscuts. Quarterly output summaries inform our sustainability reports, showing material utilization rising since adopting laser technology.

Valencia –

We source FSC-certified plywood and list the actual off-cut percentage on marketing. After switching to laser, waste fell below six percent, documented by optimizer reports. Edge quality lets toys ship naturally without sanding. CO2 cartridges are recycled locally, and the machine’s low standby power fits our green ethos.

Renata –

Leather cover cutouts follow complex spine curves flawlessly. Light scorching produces an attractive caramel edge that clients request specifically. Raster embossing on front panels means fewer stamping dies. The removable slat table exposes a solid base—a feature perfect for delicately balanced pieces.

Stellan –

Mylar wings slice without tearing, and the low-pressure exhaust keeps sheets stationary. The touchscreen shows real-time path progress, letting me prep carbon spar inserts just in time. Software warns if files exceed bed size, reducing surprises. The transport case provided made it easy to carry to the test ranges.

Upton –

EVA foam armor pieces once warped under hot knives. Laser yields crisp edges that accept paint evenly. The job queue stacks overnight runs, and the chiller auto-shuts when jobs finish, saving energy. Exhaust hood duct adapter matched our studio system out of the box—no custom fab needed.

Orla –

Closed-cell foam gaskets for hatch covers are cut neatly, sealing better than die-cut versions. Low-speed air-assist stops debris from embedding in the fabric’s top layers. The maintenance wizard lists tasks by shift, so techs don’t overlook coolant checks. Our scrap barrel shrank noticeably this season.

Tamara –

Onboard camera archives every job, creating an audit trail for product liability files. Interlock sensors test themselves at startup and log status. Training mode limits beam power, letting new hires practice without risk. We passed our annual safety audit with commendations for documentation detail.