Product Introduction

Types of Handheld Laser Welding Machines

-

FW Laser Welding Machine

Rated 5.00 out of 5$4,550.00 – $21,450.00Price range: $4,550.00 through $21,450.00 Select options This product has multiple variants. The options may be chosen on the product page -

FW-A Laser Welding Machine

Rated 4.88 out of 5$6,860.00 – $9,660.00Price range: $6,860.00 through $9,660.00 Select options This product has multiple variants. The options may be chosen on the product page -

FW-P Laser Welding Machine

Rated 4.75 out of 5$4,810.00 – $21,710.00Price range: $4,810.00 through $21,710.00 Select options This product has multiple variants. The options may be chosen on the product page -

FW-AT Laser Welding Machine

Rated 4.75 out of 5$7,140.00 – $9,940.00Price range: $7,140.00 through $9,940.00 Select options This product has multiple variants. The options may be chosen on the product page -

FW-D Laser Welding Machine

Rated 4.75 out of 5$5,460.00 – $22,360.00Price range: $5,460.00 through $22,360.00 Select options This product has multiple variants. The options may be chosen on the product page -

FW-S Laser Welding Machine

Rated 4.75 out of 5$8,450.00 – $21,840.00Price range: $8,450.00 through $21,840.00 Select options This product has multiple variants. The options may be chosen on the product page -

FW-T Laser Welding Machine

Rated 4.63 out of 5$4,940.00 – $21,840.00Price range: $4,940.00 through $21,840.00 Select options This product has multiple variants. The options may be chosen on the product page -

FW-F Laser Welding Machine

Rated 4.63 out of 5$5,590.00 – $22,490.00Price range: $5,590.00 through $22,490.00 Select options This product has multiple variants. The options may be chosen on the product page

Application of Handheld Laser Welding Machines

Why Choose Us

Industrial-Grade Build Quality

Our machines are built with robust components and high-precision engineering to ensure long-term durability and consistent welding performance in demanding environments.

Advanced Technology Integration

We offer intelligent control systems, auto-focus laser heads, and real-time monitoring to deliver fast, accurate, and stable welding results.

Comprehensive Application Support

Our machines support a wide range of welding methods and materials, from thin sheets to complex assemblies, across multiple industries.

Customizable Solutions

We provide machine configurations tailored to your specific workflow, product design, and production volume for optimal performance and efficiency.

Global Service and Training

Faster Laser offers professional training, technical support, and fast-response service to ensure seamless operation and minimal downtime.

Cost-Effective Investment

Our machines combine high-quality performance with competitive pricing, helping businesses maximize productivity while minimizing energy, labor, and material waste.

Handheld Laser Welding Machines VS Other Welding Machines

| Comparison Item | Handheld Laser Welding Machine | TIG Welding Machine | MIG Welding Machine | Plasma Arc Welding Machine |

|---|---|---|---|---|

| Welding Method | Focused fiber laser beam | Tungsten electrode with filler | Wire-fed arc with shielding gas | Ionized gas arc |

| Portability | High – compact and handheld | Low | Low | Low |

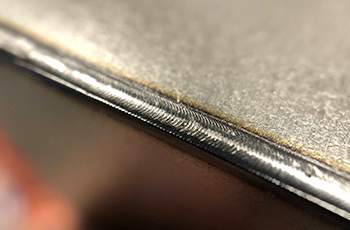

| Welding Precision | Very high | High | Moderate | Moderate |

| Welding Speed | Fast | Slow | Moderate | Fast |

| Heat Affected Zone (HAZ) | Very small | Moderate | High | Medium |

| Weld Appearance | Smooth, clean, minimal discoloration | Clean with skilled operation | May require post-processing | Rougher finish |

| Distortion Control | Excellent | Moderate | Poor | Moderate |

| Setup Time | Very short (plug and play) | Long | Moderate | Moderate |

| Skill Requirement | Low to moderate | High | Moderate | High |

| Suitable Materials | SS, CS, aluminum, brass, copper | Most metals | Most metals | Conductive metals |

| Filler Requirement | Often not required | Always required | Required | Sometimes required |

| Post-Processing Needs | Minimal | Moderate | Often needed | Often needed |

| Operating Cost | Low | Moderate to high | Moderate | Moderate |

| Maintenance | Low | Moderate | High (spatter, consumables) | High |

| Typical Applications | Kitchenware, signage, sheet metal, repair | Aerospace, pressure vessels, piping | General fabrication, structural metalwork | Cutting and joining conductive metals |

Customer Testimonials

Related Resources

Laser Welding VS MIG Welding

This article provides a detailed comparison of laser welding and MIG welding, covering principles, performance, cost, applications, and factors to consider when selecting the appropriate process.

Laser Welding VS TIG Welding

This article explains the differences between laser welding and TIG welding, covering processes, materials, equipment, costs, pros and cons, and how to choose the right method.

Frequently Asked Questions

What is Handheld Laser Welding?

- Portability: The laser gun is lightweight and easy to carry, allowing welding in tight spaces or complex angles.

- Ease of Use: Simple interface, often with preset modes for different materials and thicknesses.

- High Speed and Low Distortion: Compared to TIG or MIG, it offers faster welding with minimal heat-affected zones.

- Versatility: Suitable for a wide range of materials and joint types.

What Factors Affect The Cost Of Handheld Laser Welding Machines?

- Laser Power Output

- 1500W-2000W: Suitable for thin to medium-thickness metals; lower cost and ideal for most general welding needs.

- 3000W-6000W: Allows deeper penetration and faster speeds for thicker materials; typically more expensive.

- Impact: The higher the power, the higher the cost due to stronger laser sources and cooling requirements.

- Laser Source Brand and Quality

- Brands like IPG, Raycus, and Max differ in terms of reliability, lifespan, and warranty.

- IPG (Germany): Premium option with high precision and long life

- Raycus/Max (China): Cost-effective, widely used in mid-range machines

- Impact: Premium sources add to the price but offer better beam quality and longer service life.

- Welding Head Type: Basic handheld heads are less expensive but offer fewer features. Advanced heads may include:

- Oscillating (swinging) function for better weld quality

- 4-in-1 functionality (welding, cleaning, cutting, polishing)

- Touchscreen controls or smart sensors

- Impact: More advanced heads increase cost but enhance versatility.

- Integrated Functions

- Some machines are designed for 3-in-1 or 4-in-1 use (welding, cleaning, cutting, polishing).

- Multi-functionality increases machine complexity and price.

- Impact: If you only need welding, skip the extras to save money.

- Cooling System

- Air-cooled systems: Cheaper, lighter, but suitable only for lower power machines (≤1500W)

- Water-cooled chillers: Necessary for 2000W+ systems; more expensive but more efficient

- Impact: Cooling type directly affects cost and portability.

- Safety Features and Accessories

- Systems with laser interlocks, protective eyewear, wire feeders, and shielding gas kits will cost more upfront but improve usability and compliance.

- Impact: Better safety and productivity features justify the higher investment.

- Software and Automation Compatibility

- Machines with smart interfaces, welding presets, and automation integration command higher prices.

- Impact: Useful for repeatable tasks or less-skilled operators, but may not be necessary for basic jobs.

- Supplier, Warranty, and Support

- Machines from reputable manufacturers offer better after-sales service, technical support, and longer warranties.

- Impact: Trusted suppliers may cost more initially, but reduce long-term maintenance and downtime.

What Are The Disadvantages Of Handheld Laser Welding Machines?

- Operator-Dependent Quality: Handheld laser welding depends heavily on the user’s skill, hand stability, and motion consistency. Improper angle or speed may result in uneven seams, insufficient penetration, or defects, especially over long welds.

- Limited Suitability for Mass Production: These machines are not ideal for automated, high-volume workflows. For industries that rely on fully repeatable and robotic welding, automatic systems offer better consistency and speed.

- Gap Sensitivity: Laser welding requires precise joint fit-up with minimal gaps. If the parts are misaligned or poorly prepared, the laser beam may not bridge the joint effectively, resulting in poor weld fusion or the need for additional filler wire.

- Power Limitations on Thick Metals: Most handheld laser welding machines operate between 1500W to 6000W, which is effective for thin to medium metal thicknesses (1-8 mm). Materials thicker than 8–12 mm may require multiple passes or higher power, reducing efficiency.

- Safety Hazards: Handheld lasers emit high-powered Class 4 laser beams, which pose risks of eye injury, skin burns, or fire. Proper use of laser safety glasses, shielding, and trained operation is essential to avoid accidents.

- High Initial Cost Compared to Conventional Welding: Although more affordable than robotic laser systems, handheld laser welding machines are still more expensive than MIG or TIG machines, especially when high-power models or branded sources like IPG are chosen.

- Challenges with Reflective Materials: Metals like aluminum, brass, and copper reflect the laser beam, increasing the risk of back-reflection damage and inconsistent welds. Specialized techniques or higher power may be required.

How Do I Choose The Right Laser Power For My Welding Application?

- Material Type: Different metals absorb and conduct heat differently.

- Stainless Steel and Carbon Steel: Weld well with moderate power (1500W-3000W).

- Aluminum and Copper: Reflective and highly conductive, often requiring higher power (2000W-6000W).

- Titanium and Nickel Alloys: Typically need 1000W-2000W, especially when precision and oxidation control are priorities.

- Material Thickness: Thicker materials need more power to achieve full penetration.

- 5-2mm: 1000W-1500W is generally sufficient.

- 2-4 mm: 1500W-2000W is recommended for solid, clean welds.

- 5-6 mm: 2000W-3000W ensures deeper weld pools and faster operation.

- 6-8 mm: Consider 3000W-6000W or multiple passes with filler wire.

- Welding Speed and Productivity Goals: Higher power allows for faster welding, ideal for high-throughput environments.

- For batch production or automation, 2000W or more supports continuous, efficient welding.

- For small-scale or occasional work, 1000W–1500W may be more economical and sufficient.

- Joint Design and Fit-up:

- Tightly aligned joints (butt, lap, edge): Lower power may suffice.

- Gapped, poor-fit joints: May require higher power or filler wire to compensate.

- Welding Method:

- Conduction welding (shallow): Requires less power.

- Keyhole welding (deep): Needs higher power to create and stabilize the vapor cavity.

What Materials Can Be Welded With Handheld Laser Welding Machines?

- Stainless Steel: Stainless steel is one of the most commonly welded materials with handheld laser welders due to its good laser absorption and low thermal conductivity.

- Common Grades: 304, 316, 201

- Applications: Kitchen equipment, furniture, pipelines, medical instruments

- Weld Quality: High; produces clean, strong, corrosion-resistant seams

- Carbon Steel (Mild Steel): Handheld lasers can weld low- and medium-carbon steels effectively, provided proper shielding gas (typically argon) is used to prevent oxidation.

- Applications: Automotive parts, structural components, metal doors

- Weld Quality: Strong welds with low distortion

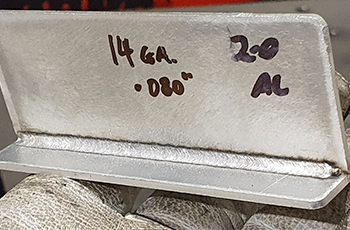

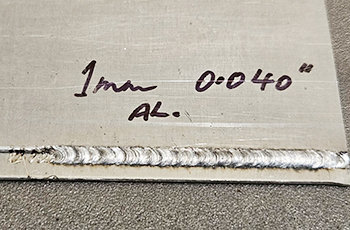

- Aluminum and Aluminum Alloys: Although aluminum is reflective and conductive, high-power handheld laser welders (≥2000W) can handle it successfully.

- Common Alloys: 6061, 5052, 1060

- Applications: Aerospace parts, window frames, auto body panels

- Weld Quality: Good, but requires tight joint fit-up and may benefit from swing-welding heads

- Galvanized Steel: Laser welding can join galvanized steel, but proper ventilation and fume extraction are essential due to zinc vaporization.

- Applications: HVAC systems, steel framing, automotive structures

- Weld Quality: Clean with good settings, but pre-cleaning may be required for consistency

- Brass and Copper: Due to their high reflectivity and thermal conductivity, welding brass and copper requires higher laser power (3000W or more) and careful parameter control.

- Applications: Electrical connectors, plumbing fixtures, decorative items

- Weld Quality: Achievable with high-power lasers, though copper is more challenging

- Titanium and Titanium Alloys: Titanium is well-suited to laser welding, especially in a shielded environment that prevents oxidation.

- Applications: Medical devices, aerospace components, chemical equipment

- Weld Quality: High-strength, corrosion-resistant seams

- Nickel and Nickel Alloys: Nickel-based materials weld well with lasers and are often used in heat-resistant and high-strength applications.

- Applications: Power plants, aerospace, electronics

- Weld Quality: Excellent when welded with proper shielding and parameters

How Do I Manage Laser Exposure Risks When Using Handheld Laser Welding Machines?

- Laser Safety Glasses

- Mandatory Protection: Always wear laser-specific safety goggles that match the laser’s wavelength (typically 1064 nm for fiber lasers) and optical density (OD).

- Why it’s important: Even indirect or reflected beams can cause permanent retinal damage.

- Recommendation: Use certified eyewear that complies with ANSI Z136 or EN 207/208 standards.

- Skin Protection

- Wear flame-retardant, long-sleeved clothing to protect against radiant heat and accidental exposure.

- Use welding gloves made from heat-resistant materials like leather or Kevlar® to shield hands from the laser beam and hot metal.

- Work Area Shielding

- Set up non-reflective barriers or welding screens around the workstation to contain stray laser reflections.

- Avoid shiny or mirrored surfaces near the welding zone, as they can reflect the beam unpredictably.

- Mark the laser zone with warning signs and restrict access to trained personnel only.

- Proper Workspace Layout

- Ensure your work area is well-lit, ventilated, and free of flammable materials.

- Use black or matte-colored fixtures around the work zone to absorb stray beams.

- Keep a fire extinguisher and first-aid kit nearby.

- Laser Interlocks and Trigger Control

- Many handheld laser welding machines come with contact sensors, safety interlocks, or double-trigger switches that disable the laser unless the head is in direct contact with metal.

- Ensure these systems are functioning properly and never bypassed.

- Ventilation and Fume Extraction

- Laser welding releases metal fumes and particles, especially with galvanized or coated materials.

- Use a local exhaust ventilation system or portable fume extractor to reduce inhalation risk and prevent contamination.

- Training and Operating Protocols

- All operators should undergo laser safety training covering beam hazards, PPE usage, and emergency procedures.

- Keep a logbook of laser usage, maintenance, and safety checks.

- Follow the manufacturer’s instructions strictly, especially for warm-up, shut-down, and maintenance routines.

- Emergency Preparedness

- Post emergency contact numbers and safety instructions in visible locations.

- Conduct regular fire and laser safety drills if operating in a shared workspace.

How Do I Maintain Handheld Laser Welding Machines?

- Protective Lens and Nozzle: Handheld laser welders use a protective lens at the laser head to shield internal optics from fumes and spatter.

- Daily Task: Clean the lens gently with lens paper and alcohol. Check the nozzle for residue or blockages and clean thoroughly.

- Why it matters: A dirty or damaged lens reduces beam focus and power, leading to weak or inconsistent welds.

- Cooling System: These machines rely on either water or air cooling to prevent overheating.

- Water-Cooled Models: Regularly check coolant levels, flush and refill with deionized water every 1–2 months, and inspect for leaks.

- Air-Cooled Models: Clear any dust or blockages from ventilation grills and internal fans weekly.

- Why it matters: Poor cooling can overheat the laser source and shorten component life.

- Shielding Gas Flow: Shielding gas (usually argon or nitrogen) protects the weld from oxidation.

- Weekly Task: Check gas lines, connections, and regulators for leaks or clogging. Ensure proper gas pressure and flow rate.

- Why it matters: Inadequate gas flow can cause weld defects like porosity or discoloration.

- Electrical and Optical Connections:

- Weekly Task: Inspect the power cable, laser gun connectors, and control panel for wear, burns, or looseness. Tighten or replace as needed.

- Monthly Task: Check the laser source housing and grounding system.

- Why it matters: Electrical faults or loose connections can cause power loss or safety risks.

- Laser Software and Control Panel:

- As Needed: Backup settings and check for firmware updates. Clean touchscreens and test emergency stop functionality.

- Why it matters: Ensures reliable and user-friendly operation.

- Consumables Replacement:

- Periodically: Replace worn lenses, copper nozzles, and ceramic isolators as performance begins to decline.

- Why it matters: These components wear down over time and can affect beam alignment and weld consistency.

What Is The Lifespan Of Handheld Laser Welding Machines?

- Fiber Laser Source: The heart of the machine, the fiber laser module, is designed for durability.

- Lifespan: Up to 100,000 working hours

- Note: High-quality laser sources from reputable brands like IPG, Raycus, or Max offer superior longevity and performance. Proper cooling and dust-free environments significantly extend service life.

- Welding Head and Optical Components: The handheld welding gun contains critical optics such as focus lenses and protective windows.

- Lifespan: 3-5 years on average for the complete head assembly

- Note: Internal components like nozzles, lenses, and ceramic rings are consumables and may require replacement every few weeks or months, depending on workload.

- Cooling System: Essential to prevent overheating of the laser source.

- Lifespan: 5-7 years for water chillers or air-cooling systems

- Note: Regular coolant replacement, dust cleaning, and leak inspection will help extend the lifespan.

- Electrical and Control Components: Includes the control board, power supply, and user interface.

- Lifespan: Typically 8-10 years

- Note: Voltage stability, moisture control, and protection against overloads are key to durability.

- Overall System Lifespan:

- With proper care, the full handheld laser welding machine can function reliably for 8 to 12 years.

- Note: Machines used in clean, climate-controlled workshops with regular maintenance will outlast those used in harsh environments.