Product Introduction

Types of Automatic Laser Welding Machines

-

FW-PA Laser Welding Machine

Rated 4.63 out of 5$13,650.00 – $30,550.00Price range: $13,650.00 through $30,550.00 Select options This product has multiple variants. The options may be chosen on the product page -

FW-R Laser Welding Robot

Rated 4.63 out of 5$17,550.00 – $34,450.00Price range: $17,550.00 through $34,450.00 Select options This product has multiple variants. The options may be chosen on the product page

Application of Automatic Laser Welding Machines

Why Choose Us

Industrial-Grade Build Quality

Our machines are built with robust components and high-precision engineering to ensure long-term durability and consistent welding performance in demanding environments.

Advanced Technology Integration

We offer intelligent control systems, auto-focus laser heads, and real-time monitoring to deliver fast, accurate, and stable welding results.

Comprehensive Application Support

Our machines support a wide range of welding methods and materials, from thin sheets to complex assemblies, across multiple industries.

Customizable Solutions

We provide machine configurations tailored to your specific workflow, product design, and production volume for optimal performance and efficiency.

Global Service and Training

Faster Laser offers professional training, technical support, and fast-response service to ensure seamless operation and minimal downtime.

Cost-Effective Investment

Our machines combine high-quality performance with competitive pricing, helping businesses maximize productivity while minimizing energy, labor, and material waste.

Automatic Laser Welding Machines VS Other Welding Machines

| Comparison Item | Automatic Laser Welding Machine | TIG Welding Machine | MIG Welding Machine | Plasma Arc Welding Machine |

|---|---|---|---|---|

| Welding Method | Focused laser beam + CNC/robotic automation | Tungsten electrode with manual filler | Wire-fed arc with shielding gas | High-temperature ionized gas arc |

| Precision | Very high | High | Moderate | Moderate |

| Welding Speed | Fast, continuous | Slow | Moderate | Fast |

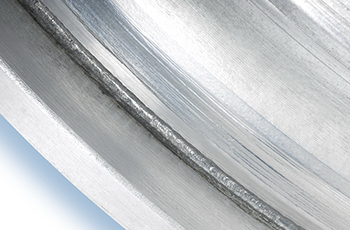

| Heat Affected Zone (HAZ) | Minimal | Moderate | High | Medium |

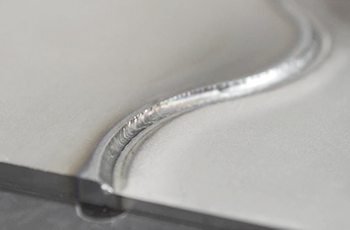

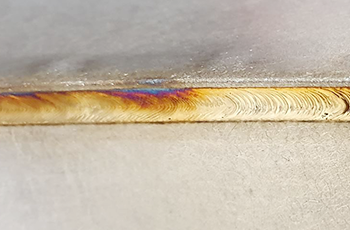

| Weld Aesthetics | Smooth, clean, minimal post-processing | Clean but requires skill | May need grinding or finishing | Rougher finish |

| Distortion Control | Excellent | Moderate | Poor | Moderate |

| Automation Capability | Fully automated (CNC/robotic integration) | Limited | Moderate | Moderate |

| Suitable Materials | SS, CS, aluminum, brass, copper | Most metals | Most metals | Conductive metals only |

| Filler Material Requirement | Often not needed | Always required | Always required | Sometimes required |

| Thickness Range | Thin to medium | Thin to thick | Medium to thick | Medium |

| Operating Cost | Low (efficient energy use, minimal waste) | Moderate to high | Moderate | Moderate |

| Maintenance Needs | Low | Moderate | High (spatter, wire feed) | High |

| Production Throughput | High, suitable for mass production | Low | Moderate | High |

| Skill Dependency | Low (automated operation) | High (manual skill required) | Moderate | High |

| Common Applications | Automotive, appliances, electronics, medical | Aerospace, pipelines, structural welding | Metal fabrication, repair | Cutting and welding conductive materials |

Customer Testimonials

Related Resources

Laser Welding VS TIG Welding

This article provides a detailed comparison of laser welding and TIG welding, covering their processes, advantages, limitations, applications, and key differences.

Frequently Asked Questions

What is Automatic Laser Welding?

- CNC or Robotic Integration: Machines are controlled via a computer interface or PLC system, enabling multi-axis movement for complex geometries.

- Pre-Set Welding Parameters: Laser power, speed, focus, and shielding gas flow are automatically adjusted based on the programmed job.

- Consistent Quality: Repeatable, high-quality welds are achieved without variation caused by human error or fatigue.

- Automated Loading/Unloading (optional): High-end systems include conveyor belts, rotary tables, or robot arms for material handling.

What Power Options Are Available For Automatic Laser Welding Machines?

- 1500W: Automatic laser welding machines with 1500 watts of power are ideal for thin to medium-thickness materials, typically ranging from 0.5 mm to 2 mm.

- Materials: Stainless steel, carbon steel, aluminum

- Applications: Metal furniture, thin sheet enclosures, automotive parts, signage

- Advantages: Energy-efficient, minimal distortion, suitable for precision parts

- 2000W: With 2000 watts, these machines can weld materials up to 2-3 mm thick at faster speeds and with greater penetration.

- Materials: Carbon steel, stainless steel, aluminum alloys

- Applications: Medium-duty frames, kitchen appliances, mechanical housings

- Advantages: Balances productivity with precision, commonly used in industrial automation

- 3000W: At 3000 watts, automatic laser welding systems can handle thicker materials (up to 3-5 mm) and more demanding welds.

- Materials: Stainless steel, mild steel, high-strength steel, aluminum

- Applications: Structural components, machinery parts, battery packs

- Advantages: High-speed operation with deep welds, suitable for continuous production lines

- 6000W: The most powerful option in this range, 6000W laser welders can cut through heavy metals up to 6-8 mm thick or more, depending on joint design.

- Materials: Thick carbon steel, stainless steel, aluminum, and copper

- Applications: Automotive chassis, aerospace parts, large-scale industrial equipment

- Advantages: Enables keyhole welding with deep penetration, high throughput, and robust weld strength

What Materials Can Be Welded With Automatic Laser Welding Machines?

- Carbon Steel: Automatic laser welding provides excellent weld strength and consistency when joining mild or low-carbon steels.

- Common Uses: Automotive frames, pipes, enclosures

- Notes: Oxygen shielding can be used, but argon or nitrogen is preferred to minimize oxidation.

- Stainless Steel: Highly compatible with laser welding due to its good absorption and low thermal conductivity.

- Common Uses: Kitchenware, medical devices, cabinets, battery cases

- Notes: Produces clean, corrosion-resistant welds when paired with argon shielding gas.

- Aluminum and Aluminum Alloys: Although reflective and thermally conductive, aluminum can be effectively welded using high-power fiber lasers.

- Common Uses: Aerospace structures, battery trays, automotive panels

- Notes: Nitrogen or argon shielding is essential to prevent porosity and oxidation.

- Copper and Copper Alloys (e.g., Brass): Difficult to weld using traditional methods, but automatic laser systems with high-power lasers (≥3000W) or green lasers can achieve strong, clean welds.

- Common Uses: Electrical connectors, busbars, heat exchangers

- Notes: Requires precise control due to reflectivity and heat dissipation.

- Titanium and Titanium Alloys: Ideal for aerospace and medical applications where strength, weight, and corrosion resistance are critical.

- Common Uses: Implants, aircraft components, chemical vessels

- Notes: Requires a high-purity argon shielding environment to avoid contamination.

- Nickel and Nickel-Based Alloys (e.g., Inconel): Welded effectively using automated laser systems in high-temperature and corrosion-resistant applications.

- Common Uses: Jet engines, power plant components, chemical equipment

- Notes: Laser welding offers precision and consistency for these high-value materials.

- Precious Metals (Gold, Silver, Platinum): Often used in jewelry, medical devices, and electronics, these metals benefit from low-distortion, localized welding.

- Common Uses: Watch components, electrical contacts, implantable devices

- Notes: Requires low power and high control for delicate parts.

What Types Of Joints Are Suitable For Automatic Laser Welding?

- Butt Joints: Two metal pieces are joined edge-to-edge in the same plane.

- Best suited for: Sheet metal, frames, enclosures

- Advantages: Clean, smooth welds with minimal filler

- Automation Benefits: High-speed and consistent alignment make it ideal for robotic systems

- Lap Joints: One workpiece overlaps another, with the weld running along the edge.

- Best suited for: Dissimilar thicknesses, automotive panels, battery tab welding

- Advantages: Tolerates slight misalignment better than butt joints

- Automation Benefits: Reliable for high-throughput applications where tiga ht fit-up is achievable

- T-Joints: One piece is joined perpendicular to another, forming a “T” shape.

- Best suited for: Structural assemblies, brackets, chassis components

- Advantages: Strong mechanical connection, accessible from multiple angles

- Automation Benefits: Multi-axis or robotic systems can easily handle vertical or side welds

- Corner Joints: Two plates meet at a right angle, joined along the outer edge.

- Best suited for: Enclosures, sheet metal boxes, appliance housings

- Advantages: Seam welds provide a clean appearance and strength

- Automation Benefits: Perfect for laser welding heads mounted on a gantry or robotic arms

- Edge Joints: Two metal sheets are joined at their edges, often used for sealing.

- Best suited for: Tubes, containers, battery housings

- Advantages: Narrow, sealed seams for air- or fluid-tight applications

- Automation Benefits: Ideal for high-speed production where edge alignment is well-controlled

What Are The Disadvantages Of Automatic Laser Welding Machines?

- High Initial Investment: Automatic laser welding systems are expensive to acquire due to the combination of fiber laser sources, robotic arms, CNC controllers, vision systems, and safety enclosures. This cost can be prohibitive for small or low-volume manufacturers without a strong return on investment plan.

- Strict Fit-Up Requirements: These machines require tight joint tolerances—typically less than 0.1 mm gap—for consistent, filler-free welding. If workpieces are misaligned or have varying gaps, the weld may suffer from a lack of fusion, underfill, or spatter, reducing quality and strength.

- Limited Gap Bridging: Unlike MIG or TIG welding, laser welding is less effective when weld joints are poorly prepared or involve inconsistent gaps, unless filler wire is added (which slows down the process and increases complexity).

- Challenging Reflective Material Welding: Materials like aluminum, copper, and brass are difficult to weld due to their high reflectivity and thermal conductivity. These often require high-power lasers, beam wobble techniques, or special coatings, increasing cost and setup complexity.

- Complex Setup and Programming: Integration of automation—including robot paths, welding parameters, and vision systems—requires experienced personnel and advanced programming knowledge, making initial deployment time-consuming.

- Maintenance Demands: Automatic systems consist of many parts, such as servo motors, sensors, chillers, and optical components. These require regular maintenance, calibration, and occasional replacement, leading to downtime if not managed properly.

- Stringent Safety Requirements: High-powered lasers present risks including eye injury, skin burns, and fire hazards. Compliance with laser safety standards (e.g., Class 4 laser enclosures, interlocks, warning lights) is essential, increasing facility setup costs.

What Are The Hazards Of Automatic Laser Welding?

- Laser Radiation Exposure: Fiber lasers used in welding are typically Class 4 lasers, which emit high-intensity, invisible near-infrared radiation (often at 1064 nm).

- Hazard: Direct or reflected exposure can cause permanent eye damage or skin burns, even from beam reflections off shiny surfaces.

- Prevention: Use laser safety enclosures, interlock systems, and wavelength-specific laser safety glasses.

- Fire and Burn Hazards: The laser generates extreme heat that can easily ignite flammable materials or cause burns on contact.

- Hazard: Combustible dust, packaging materials, or oil residues near the work area can catch fire.

- Prevention: Keep the area clean, remove flammable objects, and equip the workspace with fire suppression systems.

- Fume and Gas Emissions: Laser welding produces metallic fumes, particulates, and gases, especially when welding stainless steel, coated metals, or aluminum.

- Hazard: Inhalation of fumes (e.g., hexavalent chromium, aluminum oxide) can harm the respiratory system.

- Prevention: Use local exhaust ventilation, fume extractors, and respirators when needed.

- Electrical Hazards: Automatic systems rely on high-voltage components to power the laser source and motion control systems.

- Hazard: Electric shock, short circuits, or equipment fire from damaged cables or poor grounding.

- Prevention: Regularly inspect wiring, use proper grounding, and follow lockout/tagout procedures during maintenance.

- Mechanical Hazards: Automatic systems include moving chucks, robotic arms, and CNC axes.

- Hazard: Pinch points, crush zones, or unexpected movements can cause serious injury.

- Prevention: Install physical barriers, safety light curtains, and emergency stop switches.

- Noise and Light Exposure: Some laser welding setups generate intense light flashes and mechanical noise.

- Hazard: Potential hearing damage or visual fatigue from arc light.

- Prevention: Use sound-dampening enclosures and laser-safe viewing windows.

What Is The Lifespan Of Automatic Laser Welding Machines?

- Fiber Laser Source: Automatic laser welding machines typically use fiber lasers, which are known for their exceptional durability.

- Lifespan: Up to 100,000 working hours, or about 10-12 years under regular operation

- Note: Performance remains stable with minimal degradation, especially when the chiller and optics are well maintained.

- Welding Head and Optics

- Lifespan: Around 3-5 years, depending on the frequency of use and cleanliness of the environment

- Note: Lenses, protective windows, and nozzles are consumable parts and may need more frequent replacement.

- Mechanical and Motion Systems

- Lifespan: 8-10 years for CNC gantries, robotic arms, and servo motors, assuming regular lubrication and recalibration

- Note: Vibration, misalignment, or poor lubrication can shorten this lifespan.

- Cooling System (Water Chiller)

- Lifespan: Typically 5-7 years

- Note: Using deionized water and regularly flushing the system prevents scaling and prolongs service life.

- Control System and Software

- Lifespan: Around 5-10 years, depending on system updates and compatibility

- Note: Software updates and hardware upgrades may extend usability beyond the original service window.

How Do I Maintain Automatic Laser Welding Machines?

- Optics and Welding Head: The protective lens, focus lens, and nozzle should be checked daily for contamination, spatter, or wear. Clean the lenses with isopropyl alcohol and lint-free tissue, and replace them if scratched or discolored to prevent beam distortion or power loss.

- Cooling System: Most machines use water chillers to prevent overheating. Maintain coolant temperature between 22℃–26℃, top off with deionized water, and clean or flush the system monthly to prevent mineral buildup or algae growth that can damage the laser source.

- Shielding Gas System: Confirm that argon, nitrogen, or air flow is stable and at the correct pressure. Check hoses and fittings for leaks or blockages to ensure a clean weld environment and prevent oxidation or porosity.

- Mechanical Components: Lubricate the guide rails, ball screws, and robotic joints weekly. Inspect motion systems for unusual vibrations, backlash, or wear. Proper alignment and lubrication extend component life and maintain welding accuracy.

- Electrical and Control Systems: Check for loose connectors, worn cables, and abnormal heating in the control panel. Clean fans and filters to prevent dust accumulation. Test emergency stop buttons and safety interlocks monthly to ensure full compliance with laser safety protocols.

- Software and Calibration: Backup welding programs and configuration files. Run routine calibration checks on seam tracking, vision systems, or height sensors to ensure automation accuracy, especially in multi-axis robotic welding systems.