Product Introduction

Types of Laser Welding Machines

-

FW Laser Welding Machine

Rated 5.00 out of 5$4,550.00 – $21,450.00Price range: $4,550.00 through $21,450.00 Select options This product has multiple variants. The options may be chosen on the product page -

FW-A Laser Welding Machine

Rated 4.88 out of 5$6,860.00 – $9,660.00Price range: $6,860.00 through $9,660.00 Select options This product has multiple variants. The options may be chosen on the product page -

FW-P Laser Welding Machine

Rated 4.75 out of 5$4,810.00 – $21,710.00Price range: $4,810.00 through $21,710.00 Select options This product has multiple variants. The options may be chosen on the product page -

FW-AT Laser Welding Machine

Rated 4.75 out of 5$7,140.00 – $9,940.00Price range: $7,140.00 through $9,940.00 Select options This product has multiple variants. The options may be chosen on the product page -

FW-D Laser Welding Machine

Rated 4.75 out of 5$5,460.00 – $22,360.00Price range: $5,460.00 through $22,360.00 Select options This product has multiple variants. The options may be chosen on the product page -

FW-S Laser Welding Machine

Rated 4.75 out of 5$8,450.00 – $21,840.00Price range: $8,450.00 through $21,840.00 Select options This product has multiple variants. The options may be chosen on the product page -

FW-T Laser Welding Machine

Rated 4.63 out of 5$4,940.00 – $21,840.00Price range: $4,940.00 through $21,840.00 Select options This product has multiple variants. The options may be chosen on the product page -

FW-F Laser Welding Machine

Rated 4.63 out of 5$5,590.00 – $22,490.00Price range: $5,590.00 through $22,490.00 Select options This product has multiple variants. The options may be chosen on the product page

Application of Laser Welding Machines

Why Choose Us

Industrial-Grade Build Quality

Our machines are built with robust components and high-precision engineering to ensure long-term durability and consistent welding performance in demanding environments.

Advanced Technology Integration

We offer intelligent control systems, auto-focus laser heads, and real-time monitoring to deliver fast, accurate, and stable welding results.

Comprehensive Application Support

Our machines support a wide range of welding methods and materials, from thin sheets to complex assemblies, across multiple industries.

Customizable Solutions

We provide machine configurations tailored to your specific workflow, product design, and production volume for optimal performance and efficiency.

Global Service and Training

Faster Laser offers professional training, technical support, and fast-response service to ensure seamless operation and minimal downtime.

Cost-Effective Investment

Our machines combine high-quality performance with competitive pricing, helping businesses maximize productivity while minimizing energy, labor, and material waste.

Laser Welding Machines VS Other Welding Machines

| Comparison Item | Laser Welding Machine | TIG Welding Machine | MIG Welding Machine | Plasma Arc Welding Machine |

|---|---|---|---|---|

| Welding Method | Focused laser beam | Tungsten electrode with filler rod | Wire-fed arc welding | Ionized gas arc |

| Precision | Very high | High | Moderate | Moderate |

| Welding Speed | Fast | Slow | Moderate to fast | Fast |

| Heat Affected Zone (HAZ) | Minimal | Moderate | High | Medium |

| Weld Aesthetics | Clean, smooth, minimal discoloration | Clean, requires skill | May require finishing | May require post-processing |

| Material Distortion | Very low | Moderate | High | Medium |

| Suitable Materials | SS, CS, aluminum, brass, copper | Most metals | Most metals | Conductive metals |

| Thickness Range | Thin to medium | Thin to thick | Medium to thick | Medium |

| Filler Material Required | Not always needed | Yes | Yes | Sometimes |

| Automation Compatibility | Excellent | Limited | Moderate | Moderate |

| Operating Cost | Low | Moderate to high | Moderate | Moderate |

| Maintenance Requirements | Low | Moderate | High (spatter, wire feed issues) | High |

| Operator Skill Requirement | Low to moderate (automated/handheld options) | High | Moderate | High |

| Welding Speed on Thin Materials | Very fast | Slow | Moderate | Moderate |

| Common Applications | Precision welding, electronics, automotive | Aerospace, pipelines, structural welding | Fabrication, repair, general metalwork | Cutting and joining conductive metals |

Customer Testimonials

Related Resources

Laser Welding VS MIG Welding

This article provides a detailed comparison of laser welding and MIG welding, covering principles, performance, cost, applications, and factors to consider when selecting the appropriate process.

Laser Welding VS TIG Welding

This article explains the differences between laser welding and TIG welding, covering processes, materials, equipment, costs, pros and cons, and how to choose the right method.

Frequently Asked Questions

What is Laser Welding?

What Materials Can Laser Welding Machines Weld?

- Carbon Steel: Laser welding delivers deep penetration and strong joints in mild steel, making it suitable for automotive frames, machinery parts, and structural applications. With proper shielding gas, it produces clean, spatter-free welds.

- Stainless Steel: One of the most laser-friendly materials, stainless steel responds well to both conduction and keyhole welding. It’s widely used in kitchen equipment, medical devices, and enclosures, offering excellent corrosion resistance and aesthetics.

- Aluminum and Aluminum Alloys: Aluminum is highly reflective and conductive, but fiber laser welding machines, with sufficient power, can achieve clean welds with minimal porosity and low distortion. Ideal for automotive, aerospace, and battery casings.

- Copper and Brass: These conductive and reflective metals require high-power fiber lasers and often green or pulsed laser sources. With the right parameters, laser welding is effective for electrical connectors, busbars, and heat sinks.

- Titanium and Titanium Alloys: Titanium’s low thermal conductivity and high strength make it ideal for laser welding in aerospace, medical implants, and defense applications. Inert gas shielding (e.g., argon) is critical to avoid contamination.

- Nickel and Nickel Alloys: Laser welding handles nickel-based alloys such as Inconel with precision, making it useful for jet engines, chemical processing, and marine equipment due to their high-temperature and corrosion resistance.

- Precious Metals (Gold, Silver, Platinum): Laser welding is widely used in jewelry and electronics, where clean seams and minimal heat input are critical. These metals are often welded using low-power or pulsed laser systems.

How Do I Determine The Laser Power Required For My Welding Application?

- Material Type: Different metals absorb and conduct laser energy differently.

- Stainless Steel and Carbon Steel: These absorb laser energy efficiently, allowing for deep welds at moderate power levels.

- Aluminum and Copper: These are highly reflective and thermally conductive, so they require higher power to achieve proper penetration.

- Titanium and Nickel Alloys: Weld well at moderate power but require precise shielding to prevent oxidation.

- Material Thickness:

- Thin materials (0.5-1 mm): Suitable for 300W-500W lasers. Common in electronics and fine welding tasks.

- Medium thickness (1-2 mm): Requires 500W-1500W lasers. Ideal for general manufacturing, enclosures, and kitchenware.

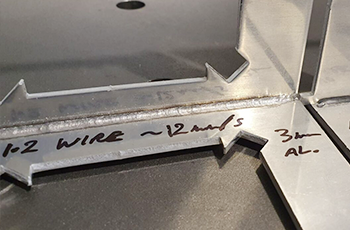

- Thick sections (2-6 mm): Require 1500W-3000W or more for strong, full-penetration welds used in automotive and machinery.

- Very thick materials (6 mm+): May need 3kW-6kW lasers, often paired with multi-pass techniques or filler wire.

- Welding Speed and Precision:

- Faster welding speeds demand higher laser power to maintain proper fusion.

- Slower speeds or fine detail work can use lower power to avoid overheating or burning through.

- Joint Fit-Up and Design:

- Tight-fitting joints (butt, lap) need less power.

- Poor fit-up or gaps may require more power and possibly filler wire to bridge the space.

- Welding Mode:

- Conduction mode welding uses lower power for shallow, smooth seams.

- Keyhole mode welding uses higher power to create deep, narrow welds through vaporization and penetration.

What Joint Designs Are Best Suited For Laser Welding?

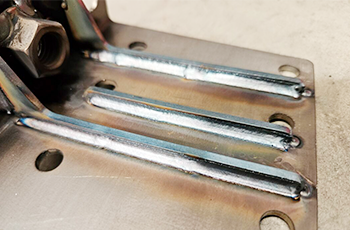

- Butt Joints: Laser welding works best with well-aligned butt joints, where two metal pieces are placed edge-to-edge. These joints are ideal for sheet metal, battery tabs, and precision components. When the gap is minimal (usually less than 0.1 mm), autogenous (filler-free) welding is possible.

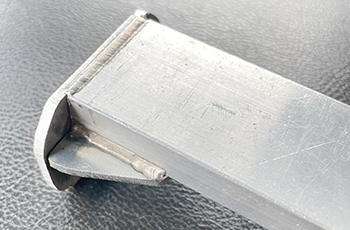

- Lap Joints: Created when one sheet overlaps another, lap joints are commonly used for thin metals, automotive panels, and dissimilar material welding. The laser melts through the top layer and into the bottom layer, producing a strong fused area along the overlap.

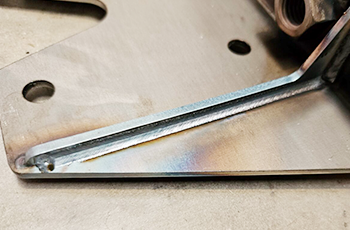

- T-Joints: Formed when one piece is joined perpendicularly to another, like a “T”. Laser welding is effective for T-joints in frames, brackets, and housing structures, as long as there is clear access for the beam to reach the weld zone.

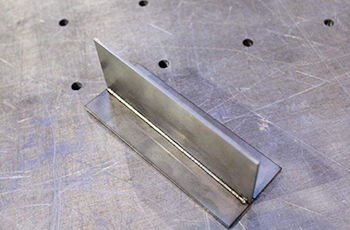

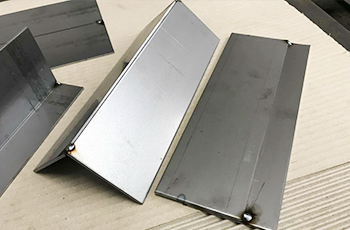

- Edge Joints: Used when two sheets are joined along their edges, this joint type is suitable for caps, containers, and sealed tubes. Laser welding provides a clean, tight seam that’s often gas- or liquid-tight.

- Corner Joints: These joints are formed where two metal plates meet at a right angle. Laser welding is frequently used for box-type enclosures, cabinets, and electronic housings, especially where an aesthetically clean outer seam is required.

How Does Laser Welding Reduce Thermal Deformation Of Materials?

- Highly Focused Heat Input: Laser welding concentrates energy into a small focal point, often less than 0.5 mm in diameter. This tight focus melts only the material at the joint, limiting heat diffusion into adjacent areas. As a result, there’s minimal expansion and contraction of the surrounding metal, which reduces warping or distortion.

- Low Heat-Affected Zone (HAZ): The heat-affected zone is much smaller in laser welding than in arc or TIG welding. A smaller HAZ means less material is softened or altered by heat, preserving the mechanical properties and dimensions of nearby regions.

- High Welding Speed: Laser welding operates at much faster speeds, which means the heat doesn’t dwell on the material for long. Shorter exposure time reduces the likelihood of thermal stress buildup, helping maintain dimensional accuracy in thin or sensitive parts.

- Minimal Filler Usage: Since laser welding can often be performed autogenously (without filler wire), there’s no added material that could alter the heat balance or expand unevenly during solidification. This further limits internal stress.

- Precise Control: Laser welding systems use CNC control and real-time sensors to maintain exact positioning, laser power, and beam movement. This precision helps ensure that only the intended joint area is affected, avoiding unintended heating of surrounding features.

- Ideal for Thin Materials and Micro Components: Because of the above factors, laser welding is especially beneficial for thin sheets, delicate assemblies, and fine electronics, where even slight warping would render a part unusable.

What Personal Protective Equipment Is Required When Using Laser Welding Machines?

- Laser Safety Glasses: Laser welding emits intense, invisible radiation, particularly from fiber lasers operating around 1064 nm. Operators must wear laser safety glasses that match the laser’s wavelength and optical density (OD rating). Without proper eyewear, even indirect exposure can cause permanent eye damage.

- Flame-Resistant Clothing: Operators should wear non-reflective, flame-retardant garments, such as welding jackets, aprons, or coveralls. Materials like cotton treated for flame resistance or leather are preferred. Synthetic fabrics like nylon or polyester must be avoided, as they can melt and stick to skin.

- Protective Gloves: Heat-resistant welding gloves made from leather protect hands from hot metal, sparks, and radiant heat. They are essential when handling freshly welded parts or working near the welding zone.

- Face Shield or Welding Helmet (if applicable): For open laser systems or high-power applications, operators may need additional face protection. A helmet or shield with laser-rated filters protects the face from thermal radiation, bright arcs, and flying particles.

- Respiratory Protection: Laser welding can release toxic metal fumes and particulates, especially when working with stainless steel, galvanized metals, or aluminum. A fume extraction system should be used. In areas without adequate ventilation, operators should wear N95 masks or powered air-purifying respirators (PAPRs).

- Steel-Toed Footwear: Welding boots or steel-toe shoes with heat- and slip-resistant soles protect against falling metal parts and hot debris on the floor.

Is It Necessary To Use Gas When Using Laser Welding?

- Protection Against Oxidation: Laser welding generates intense heat, which causes the molten metal to react rapidly with oxygen, nitrogen, or moisture in the air. Without a shielding gas, this leads to oxidation, porosity, discoloration, and weakened welds, especially in reactive metals like aluminum, stainless steel, or titanium. Shielding gases commonly used:

- Argon: The most widely used gas; provides excellent protection, especially for stainless steel, aluminum, and titanium.

- Nitrogen: Used for certain stainless steel grades to improve weld appearance and corrosion resistance.

- Helium: Offers deeper penetration but is more expensive; sometimes mixed with argon.

- Compressed Air: A budget-friendly option for welding mild steel or low-sensitivity applications.

- Improved Weld Appearance

- Shielding gas helps produce smooth, shiny weld seams by preventing surface contamination. Without it, welds may appear dark, rough, or burnt.

- Stabilization of the Laser Arc and Keyhole

- In deep-penetration (keyhole) laser welding, gas flow helps stabilize the molten pool and vapor cavity, preventing spatter and keyhole collapse that can lead to voids or defects.

- Assist with Cooling and Spatter Removal

- Shielding gas can help dissipate heat around the weld area and blow away molten metal spatter, especially useful in high-speed or robotic welding systems.

- When Gas May Not Be Necessary

- Enclosed, High-Purity Chambers: In specialized environments like glove boxes or vacuum chambers, external shielding gas may not be required.

- Certain Low-Power Micro Welds: Some extremely thin materials or very small welds may not require gas if oxidation is tolerable or controlled.

What Are The Recommended Environmental Conditions For Laser Welding Machines?

- Ambient Temperature

- Recommended Range: 18℃ to 26℃ (64℉ to 79℉)

- Why It Matters: Fiber laser sources and their cooling systems work best within this moderate temperature range. High temperatures can cause thermal drift, overheating, and reduced beam quality, while low temperatures may lead to condensation inside the optics or control systems.

- Humidity Levels

- Recommended Range: 40% to 60% relative humidity

- Why It Matters: Excess humidity can lead to corrosion of optical components, electrical short circuits, and condensation inside the laser head or cooling system. Extremely dry air (under 30%) may promote static buildup, especially in electronics.

- Dust and Air Quality

- Requirement: Clean, dust-free environment with air filtration

- Why It Matters: Dust, fumes, and airborne particles can settle on laser lenses, mirrors, and electronics, degrading weld quality and causing overheating or alignment issues. Welding should be done in areas with exhaust ventilation and, ideally, fume extraction systems.

- Vibration and Movement

- Requirement: Stable floor with minimal vibration

- Why It Matters: Laser welding demands precise beam positioning. Vibrations from nearby equipment or foot traffic can cause weld misalignment, beam instability, or focus loss. Use isolation pads or dedicated foundations when necessary.

- Lighting and Safety Measures

- Requirement: Controlled lighting with proper laser safety zoning

- Why It Matters: Excess ambient light can interfere with camera-guided systems or sensors. Ensure the laser area is marked, equipped with interlocks, warning lights, shielding, and emergency stop buttons.

- Power Supply Stability

- Requirement: Consistent voltage with surge protection or UPS

- Why It Matters: Voltage fluctuations can damage sensitive electronics or cause the laser to shut down unexpectedly. Three-phase stable power with a grounding system is ideal for industrial systems.

- Cooling Water Quality

- Requirement: Use distilled or deionized water in the water chiller

- Why It Matters: Poor water quality can lead to scaling, corrosion, or laser head damage. The chiller should be cleaned and refilled periodically based on the manufacturer’s recommendations.