Understanding Rust and Its Challenges

Overview of Rust Removal Methods

What is Laser Rust Removal?

Definition and Working Principle

Laser rust removal is based on laser ablation, a process where laser energy is directed at a rusted surface. The key principle lies in the different optical and thermal properties of rust compared to bare metal:

- Rust (iron oxides) absorbs laser energy efficiently, heating rapidly. This causes it to either vaporize, sublimate, or flake away from the surface.

- Bare metal (carbon steel, stainless steel, iron, aluminum, copper, etc.) reflects most of the energy, preventing significant damage when parameters are correctly adjusted.

Key factors that govern efficiency include:

- Wavelength: Fiber lasers (commonly at 1064 nm) are ideal for rust absorption.

- Pulse Duration: Nanosecond or femtosecond pulses minimize heat transfer to the substrate, making it possible to clean delicate components.

- Beam Intensity and Focus: Adjustable for different depths and geometries—wide beams for bulk cleaning, focused beams for fine detail.

Types of Laser Systems Used

- Emit short, high-energy bursts of light.

- Highly controlled, with minimal thermal load on the substrate.

- Best suited for applications where precision is more important than speed, such as electronics, aerospace components, or the conservation of fragile artifacts.

- Provide a steady, uninterrupted beam.

- Clean surfaces faster but with more heat transfer.

- Common in shipbuilding, pipeline maintenance, and industrial-scale cleaning, where throughput matters most.

- Hybrid & Adjustable Systems

- Allow switching between pulsed and continuous modes.

- Increasingly popular for workshops and multi-purpose industrial environments.

Cost Analysis

Laser rust removal equipment represents a significant capital investment, but the economics change when long-term use and regulatory costs are considered.

- Initial Equipment Costs:

- Entry-level portable laser cleaning machines: $3,000–$20,000

- Mid-range industrial models: $20,000–$50,000

- High-power automated systems (robotic or CNC-integrated): $80,000+

- Operating Costs:

- No consumables such as sand, chemicals, or water.

- Maintenance is limited to optics cleaning, cooling system upkeep, and periodic component replacement.

- Electricity is the main recurring cost.

- Economic Benefits:

- Less waste disposal: no used abrasive grit or chemical sludge to manage.

- Reduced labor costs: automation minimizes operator time.

- Compliance savings: avoids fines or regulatory costs tied to hazardous dust or chemical runoff.

- Return on Investment (ROI):

- For high-use industrial facilities, ROI can be reached in 2–4 years.

- For occasional use (e.g., small repair shops), the high upfront cost may not be justified compared to sandblasting.

Advantages of Laser Rust Removal

- Precision Cleaning: Selectively targets corrosion without eroding the substrate. Ideal for thin panels, precision components, or historically valuable artifacts.

- Environmentally Friendly: No secondary waste streams; eliminates abrasive media disposal and chemical pollution.

- Minimal Surface Damage: Maintains metal dimensions and surface finishes, ensuring safety-critical tolerances remain intact.

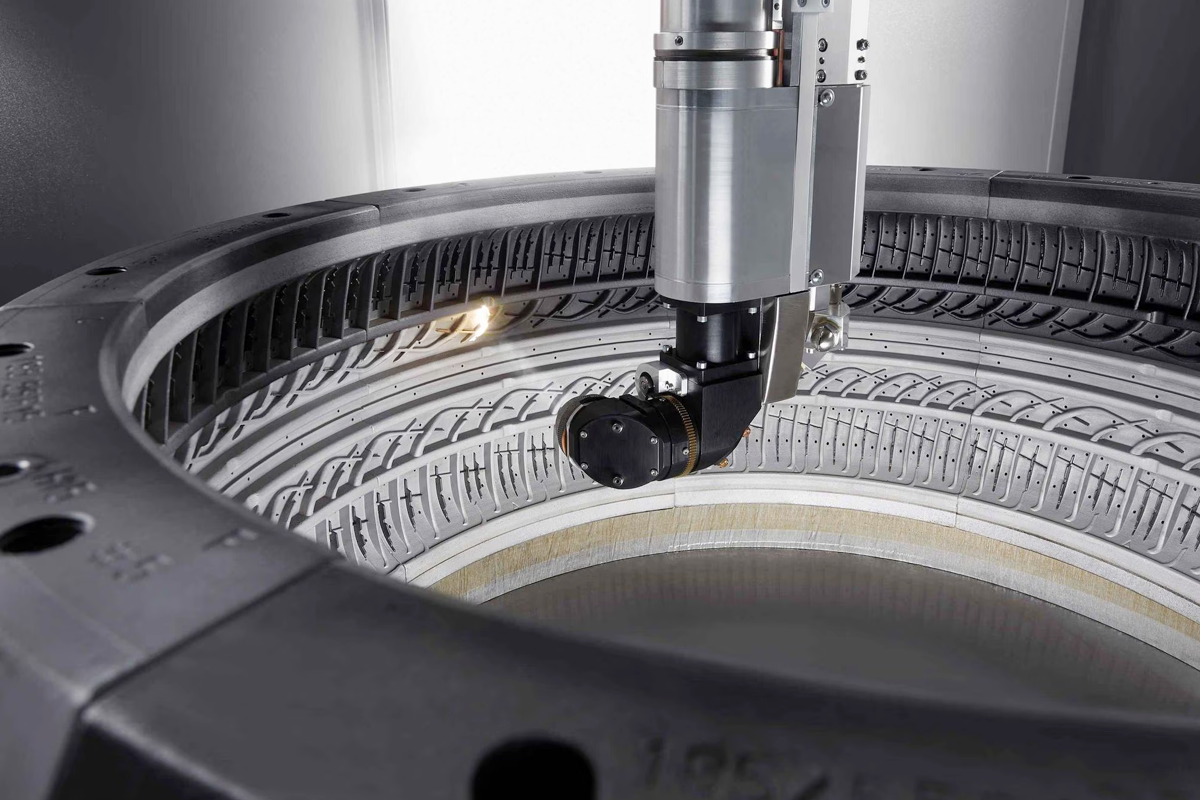

- Automation Compatibility: Can be mounted on robotic arms, conveyor systems, or CNC machines for high-volume, automated workflows.

- Versatility: Effective on different metals (steel, aluminum, copper, titanium) and adaptable to irregular geometries or hard-to-reach areas.

- Reduced Health Risks: Less dust and chemical exposure compared to abrasive blasting. Operators face fewer respiratory hazards.

- Regulatory Compliance: Aligns with increasingly strict environmental and occupational safety standards, particularly in the EU and North America.

Disadvantages of Laser Rust Removal

- High Initial Cost: A major barrier for small businesses or one-off users.

- Learning Curve: Operators must be trained to adjust wavelength, intensity, and pulse rates for different applications.

- Limited Speed for Heavy Rust: While efficient for surface corrosion, thick, deeply pitted rust is slower to remove compared to aggressive blasting.

- Electricity Demand: High-powered lasers require a stable, often industrial-grade electricity supply.

- Portability Constraints: Portable models exist but are less powerful; industrial units are not as mobile as simple sandblasting rigs.

Applications of Laser Rust Removal

- Automotive Industry: Restores chassis, body panels, and engine parts with precision. Valuable for classic car restoration, where preserving original metal is critical.

- Aerospace Sector: Cleans aircraft fuselage panels, engine components, and sensitive parts where tolerances are vital.

- Shipbuilding & Marine Industry: Removes corrosion from hulls, decks, and offshore platforms while avoiding abrasive waste pollution in marine environments.

- Industrial Manufacturing: Cleans molds, machinery, pipelines, and tooling for reuse.

- Energy Industry: Used in nuclear plants, wind turbine maintenance, and oil & gas facilities, where contamination control is essential.

- Cultural Heritage & Conservation: Safely restores monuments, sculptures, and archaeological artifacts without damaging the original material.

What is Sandblasting Rust Removal?

Definition and Process

Key steps in the process include:

- Surface Preparation: The workpiece is cleaned of grease, oils, or loose dirt.

- Abrasive Blasting: High-pressure air (or water in wet blasting systems) propels the abrasive medium onto the corroded surface.

- Surface Profiling: Along with removing rust, blasting creates a textured finish (anchor profile) that improves adhesion for primers, paints, and protective coatings.

- Cleanup and Waste Disposal: Spent media, dust, and debris are collected, often requiring significant post-blasting cleanup.

Types of Abrasive Media

The term “sandblasting” originates from the use of natural sand, but modern practices employ a wide variety of abrasives, chosen based on the application and material:

- Silica Sand: Once common, now largely restricted due to silicosis hazards.

- Aluminum Oxide: Hard, sharp, and reusable; ideal for tough corrosion removal.

- Steel Grit/Shot: Durable and effective for large-scale industrial cleaning; produces a rough profile.

- Glass Beads: Gentler; used for light rust removal and surface finishing.

- Garnet: Environmentally friendly alternative, widely used in wet blasting.

- Plastic Media: Softer; suitable for delicate components where aggressive blasting would cause damage.

- Walnut Shells / Corn Cob: Biodegradable abrasives, used in conservation and for softer surfaces.

Equipment Used

A standard sandblasting setup includes:

- Air Compressor: Provides the high-pressure air needed to propel abrasives.

- Blast Pot (or Pressure Vessel): Holds and feeds abrasive media into the air stream.

- Blast Hose and Nozzle: Direct the abrasive stream onto the surface; nozzle material must withstand heavy wear.

- Blast Cabinet or Booth (for contained blasting): Enclosed systems that reduce dust and allow media recycling.

- Protective Gear: Operators wear helmets, respirators, gloves, and full-body suits due to high dust levels and flying debris.

Cost Analysis

Sandblasting equipment is relatively inexpensive compared to laser systems, but ongoing costs add up.

- Initial Equipment Costs:

- Portable sandblasting units: $1,000–$5,000

- Industrial blasting systems and cabinets: $10,000–$25,000

- Large-scale automated booths: $50,000+

- Operating Costs:

- Abrasive media is consumable; depending on type, costs range from $0.10 to $2.00 per pound.

- Large projects require hundreds or thousands of pounds of abrasive.

- Media recycling systems can reduce costs but add complexity.

- Additional Costs:

- Protective gear, air compressors, dust collection systems, and waste disposal.

- Cleanup and disposal of contaminated grit are often significant expenses.

Advantages of Sandblasting Rust Removal

- High Removal Speed: Extremely effective at stripping heavy, deep, or stubborn rust.

- Cost-Effective Equipment: Lower initial investment compared to laser cleaning systems.

- Surface Profiling: Naturally roughens surfaces, creating an ideal foundation for paints and coatings.

- Simplicity of Operation: Equipment is relatively straightforward, and training requirements are less intensive than for laser systems.

- Versatility of Media: A wide range of abrasives available for different metals and applications.

Disadvantages of Sandblasting Rust Removal

- Surface Damage: Aggressive abrasives can thin, pit, or warp softer metals and delicate parts.

- Environmental Hazards: Generates large amounts of dust, debris, and contaminated waste. Dry blasting with silica sand is heavily regulated due to silicosis risk.

- Consumable Costs: Requires continuous purchase and disposal of abrasive materials.

- Regulatory Compliance: Increasingly restricted by environmental and workplace safety laws, especially regarding dust control and hazardous waste disposal.

- Health Risks: Without proper protection, workers face risks of lung damage, hearing loss, and injuries from flying particles.

Applications of Sandblasting Rust Removal

Sandblasting is widely used in industries where speed and aggressiveness outweigh precision:

- Shipbuilding and Marine Industry: Removes heavy corrosion from ship hulls, decks, and offshore structures.

- Construction and Infrastructure: Cleans steel beams, bridges, pipelines, and rebar before coating.

- Automotive Industry: Prepares car frames, panels, and parts, especially in large-scale restoration or repair.

- Manufacturing Maintenance: Cleans molds, machinery, and production equipment.

- Surface Coating Preparation: Ensures strong adhesion for primers, paints, and protective coatings in industrial applications.

Head-to-Head Comparison

Mode of Action

- Laser Rust Removal: Operates on the principle of laser ablation. Rust absorbs the laser’s wavelength (commonly 1064 nm in fiber lasers), heats rapidly, and either vaporizes or flakes off. Because metals reflect much of this wavelength, the base material remains intact. This non-contact method ensures precision but requires careful calibration.

- Sandblasting: A mechanical impact process. Compressed air propels abrasive particles at high velocity, physically scouring away rust, paint, and scale. While extremely effective for bulk removal, it is non-selective, removing both rust and some base material, and it can alter surface dimensions.

Mobility and Integration

- Laser: Portable handheld laser cleaning machines exist (often in the 100–500W range), but high-powered units for industrial-scale work are larger, heavier, and dependent on a stable power supply. The real strength of lasers lies in integration—they can be mounted on robotic arms, CNC machines, or conveyor systems, making them ideal for production lines and automated precision cleaning.

- Sandblasting: Highly portable in field applications. From small handheld units to truck-mounted systems, sandblasting is common on construction sites, shipyards, and oil fields. While automated blasting booths exist, they are less flexible compared to robotic laser systems in manufacturing settings.

Surface Integrity and Damage

- Laser: Maintains base metal integrity by selectively targeting only corrosion. This is critical for industries where dimensional tolerances or historical authenticity matter, such as aerospace, nuclear energy, or heritage preservation. Surfaces remain smooth or unchanged after cleaning.

- Sandblasting: Aggressively strips rust but can thin metal, introduce micro-cracks, or leave an uneven surface. On softer metals like aluminum or thin sheet steel, sandblasting can cause warping or excessive material loss.

Process Control and Selectivity

- Laser: Offers precise parameter control. Operators can adjust wavelength, pulse duration, intensity, and beam focus, tailoring the process for specific corrosion depths and materials. Lasers can even clean rust without stripping adjacent paint or coatings if required.

- Sandblasting: Provides little selectivity. Everything in the path of the abrasive stream—rust, paint, grease, and even the base metal—gets blasted away. Selectivity requires physical masking, which adds time and labor.

Precision

- Laser: Exceptionally precise. Able to target small, intricate, or complex geometries such as engine parts, fine machinery, or ornate heritage objects. Clean edges and delicate detailing are achievable without collateral damage.

- Sandblasting: Designed for broad coverage, not detail. Effective for large surfaces but unsuitable for fine, localized rust removal without risking surrounding areas.

Speed

- Laser: Effective for light-to-moderate corrosion but slower on thick, deeply pitted rust. Removing heavy scale may require multiple passes, reducing throughput in large-scale jobs.

- Sandblasting: Extremely fast for bulk cleaning. Large surfaces like ship hulls or steel beams can be stripped of rust within hours, making it the preferred choice for high-volume, time-sensitive projects.

Environmental Impact

- Laser: Clean, eco-friendly process. Produces minimal secondary waste—only small amounts of dust and debris from the rust itself. No chemicals, no contaminated water, no abrasive disposal. Increasingly seen as the sustainable option for industries facing regulatory scrutiny.

- Sandblasting: Generates massive waste streams of spent abrasive and dust, often contaminated with rust, paint, or hazardous coatings. Dry blasting with silica sand is banned or heavily regulated in many countries due to silicosis risks. Proper containment, dust extraction, and waste disposal add complexity and cost.

Equipment Cost

- Laser: Expensive to acquire.

- Portable units: $3,000–$20,000

- Mid-range industrial lasers: $30,000–$50,000

- Automated systems: $80,000+

- The upfront investment is justified for high-value applications but prohibitive for small shops.

- Sandblasting: Affordable to start.

- Portable systems: $1,000–$5,000

- Industrial blast booths: $10,000–$25,000

- Large automated setups: $50,000+

- Much more accessible for small and mid-sized businesses.

Operating Costs

- Laser: Very low ongoing costs. No consumables; only electricity, routine optics cleaning, and occasional maintenance.

- Sandblasting: Consumables are a major cost factor. Abrasives (garnet, steel grit, glass beads, etc.) are single-use or limited-reuse. Add to this waste disposal, PPE, and cleanup labor, and long-term operating costs can be significant.

Safety

- Laser: Reduces exposure to dust and toxic particles but introduces laser radiation hazards. Strict safety measures (eye protection, controlled work zones, interlocks) are required.

- Sandblasting: High noise levels, flying debris, and heavy dust exposure create serious occupational hazards. Even with PPE, long-term risks include silicosis, respiratory disease, hearing loss, and musculoskeletal injuries.

Skill Requirements

- Laser: Requires specialized training. Operators must understand laser parameters to avoid inefficiency, incomplete cleaning, or thermal damage. Higher learning curve, but once mastered, highly repeatable and automated.

- Sandblasting: Easier to learn and operate, but skill is still needed to avoid over-blasting. Less technical, but labor-intensive and physically demanding.

Scalability and Production

- Laser: Scales well in automated production environments. Robotic laser cleaning can run continuously with minimal operator input, perfect for high-value, precision manufacturing. Less suited to open-air or massive-scale jobs.

- Sandblasting: Scales best for large-scale, heavy-duty work—shipyards, bridges, pipelines, construction sites. Highly effective for industrial-scale corrosion control but less compatible with precision automation.

Laser rust removal and sandblasting serve different needs:

- Sandblasting is the workhorse of heavy industry: fast, affordable, and proven for large-scale rust removal. But it is waste-heavy, abrasive to base materials, and increasingly limited by safety and environmental regulations.

- Laser cleaning is the precision tool of modern industry: expensive to acquire but clean, safe, and exceptionally accurate. It’s best for high-value parts, sensitive industries, and organizations prioritizing sustainability.

Troubleshooting Common Clean Defects

Flash Rust

- Description: Thin reddish-brown film that reappears minutes to hours after cleaning.

- Cause: Freshly cleaned steel surfaces react rapidly with oxygen and humidity if left unprotected.

- Impact: Weakens coating adhesion and forces rework.

- Mitigation: Apply primers or inhibitors immediately after cleaning; control humidity in blasting/cleaning environments.

Uneven Cleaning / “Tiger Striping”

- Description: Visible streaks or bands where rust removal is inconsistent.

- Cause (Laser): Poor beam overlap, inconsistent speed, or wrong parameter settings.

- Cause (Blasting): Inconsistent nozzle distance, irregular motion, or uneven air pressure.

- Impact: Aesthetic defects, poor paint adhesion, and localized corrosion sites.

- Mitigation: Standardize operator technique, automate where possible, and ensure consistent equipment calibration.

Discoloration / Heat Tint / Local Temper (Laser-Specific)

- Description: Blue, brown, or straw-colored patches left on the metal after laser cleaning.

- Cause: Excessive heat input due to incorrect settings (high power density, slow scanning).

- Impact: May alter metallurgical properties locally, especially in thin or heat-sensitive components.

- Mitigation: Optimize pulse duration and scanning speed; use cooling or shielding if needed.

Over-Profiling, Edge Rounding, or Base Metal Damage (Blasting-Specific)

- Description: Surface becomes excessively rough, with rounded edges or reduced thickness.

- Cause: Overly aggressive, abrasive, excessive air pressure, or prolonged blasting in one area.

- Impact: Weakens components, increases material loss, and may cause coating overconsumption.

- Mitigation: Match abrasive hardness and size to material; regulate pressure; avoid excessive dwell time.

Poor Coating Adhesion (Peel or Early Failure)

- Description: Coating delaminates, peels, or fails prematurely.

- Cause: Surface not fully cleaned, flash rust present, improper profile (too smooth or too rough), or contamination left behind.

- Impact: Reduced service life, costly rework.

- Mitigation: Control environment, verify surface profile, test adhesion before full coating.

Embedded Media / Foreign Particle Contamination (Blasting-Specific)

- Description: Abrasive particles become lodged in the substrate surface.

- Cause: Soft base metals or improper abrasive choice.

- Impact: Acts as corrosion initiation sites; weakens coatings.

- Mitigation: Choose abrasives carefully, use clean/recyclable media, and inspect surfaces before coating.

Residues, Soot, or Re-Deposition (Laser-Specific)

- Description: Fine dark films or particulate deposits left after cleaning.

- Cause: Incomplete ablation; vaporized rust recondenses as soot.

- Impact: Interferes with coating adhesion.

- Mitigation: Adjust beam parameters, increase passes, and use airflow/vacuum extraction to carry away debris.

Access Shadows / Holidays Near Fasteners, Seals, or Recesses

- Description: Uncleaned patches in tight corners, edges, or behind fasteners.

- Cause: Nozzle or laser beam angle unable to reach concealed areas.

- Impact: Hidden corrosion continues to spread, undermining the coating system.

- Mitigation: Use smaller nozzles, angled blasting, or flexible laser optics; manually detail tricky areas.

Process Instability Day-to-Day

- Description: Inconsistent results across different shifts or workdays.

- Cause: Variations in operator technique, ambient humidity, equipment wear, or uncalibrated settings.

- Impact: Unpredictable surface quality, leading to premature failures.

- Mitigation: Standardize operating procedures, maintain equipment, and monitor environmental conditions.

Moisture-Related Clogging or “Caking” (Blasting-Specific)

- Description: Abrasive media clumps or jams during operation.

- Cause: Moisture in compressed air, damp abrasive media, or humid storage.

- Impact: Interrupts blasting, reduces cleaning efficiency, and causes uneven results.

- Mitigation: Use air dryers, properly store abrasives, and check for leaks in air systems.

Both laser rust removal and sandblasting are powerful, proven methods, but common cleaning defects can undermine results if ignored.

- Sandblasting defects typically stem from abrasive aggressiveness, contamination, and environmental moisture, leading to surface damage, embedded particles, or flash rust.

- Laser cleaning defects are more about process tuning and thermal effects, leading to discoloration, soot redeposition, or uneven results.

Choosing the Right Process

Scope and Rust Severity

- Sandblasting:

- Excels at thick, heavy corrosion layers, scale, or paint-rust composites.

- Capable of stripping steel beams, bridges, ship hulls, and large industrial tanks within hours.

- Ideal when “getting to bare metal fast” is the priority, not surface preservation.

- Laser:

- Better for light-to-moderate rust, thin oxidation films, or localized corrosion.

- Handles spot-cleaning of engine parts, fasteners, precision molds, or delicate sheet metal without damaging the substrate.

- Struggles with deeply pitted corrosion, where multiple passes increase cycle times.

- Practical Example: Restoring a classic car frame with deep rust pits is faster with blasting, but cleaning localized corrosion on a thin aluminum aerospace bracket requires laser precision.

Downstream Coating Requirements

- Sandblasting:

- Naturally produces a profiled, roughened surface (anchor profile), critical for coating adhesion.

- Coating manufacturers often specify abrasive blasting to standards like SSPC-SP10 / NACE No. 2 (Near-White Blast Cleaning) for pipelines and tanks.

- Laser:

- Produces a smooth, contamination-free surface.

- Excellent when coatings demand a clean but low-roughness base (e.g., precision machinery, aerospace alloys, or thin protective films).

- May require supplemental roughening if heavy-duty paints or epoxies need a mechanical “tooth” for adhesion.

- Practical Example: Offshore oil pipelines (requiring thick epoxy coatings) are blasted; surgical stainless components (requiring smooth passivated surfaces) are laser-cleaned.

Material and Contamination Sensitivity

- Sandblasting:

- Can over-thin steel, warp aluminum panels, or embed abrasive into softer metals.

- Not suitable for stainless steel when chloride-containing abrasives are used (risk of corrosion initiation).

- Laser:

- Gentle and non-contact, making it ideal for thin sheet metals, high-value aerospace alloys, copper, and even cultural artifacts.

- No risk of embedding foreign materials—important for food-grade, medical, or nuclear industries.

- Practical Example: Aircraft turbine blades are laser-cleaned to preserve tolerances; heavy structural steel beams for construction are blasted without concern for microns of loss.

Geometry and Access

- Sandblasting:

- Very effective for broad, open surfaces.

- Struggles in narrow crevices, recesses, or behind fasteners unless specialized nozzles or manual detail work are used.

- Laser:

- Excellent for complex geometries, seams, welds, bolt heads, and intricate castings.

- Limited by line-of-sight—beam cannot bend around corners, but fiber optics or robot arms can improve access.

- Practical Example: Blasting is perfect for clearing rust off a ship deck; laser excels at cleaning around riveted joints or inside engine compartments.

Site, Environmental, and Regulatory Constraints

- Sandblasting:

- Generates dust, noise, and waste, requiring containment systems and safe disposal.

- Many jurisdictions restrict or ban silica sand blasting due to silicosis risks.

- Requires significant environmental compliance planning.

- Laser:

- Produces minimal waste (just rust dust/particulates), easy to capture with fume extraction.

- Meets stringent environmental and workplace safety standards.

- Favored in industries with zero-tolerance policies for contamination (e.g., nuclear decontamination, medical device manufacturing).

- Practical Example: Bridge contractors still rely on blasting (with containment tarps and vacuums), but nuclear facilities increasingly adopt lasers to eliminate secondary waste streams.

Throughput, Labor, and Repeatability

- Sandblasting:

- High throughput on large surfaces—very fast for bulk cleaning.

- Labor-intensive; operator fatigue and variability affect results.

- Inconsistent profiles if pressure, angle, or media vary.

- Laser:

- Slower for heavy-duty work, but automation-ready.

- Robotic laser systems can run continuously with minimal supervision, ensuring repeatable quality.

- Labor demand is lower once systems are installed.

- Practical Example: A shipyard preparing hulls before painting uses blasting; an automotive OEM laser-cleans panels in-line before robotic coating application.

Cost Model (Capex vs. Opex)

- Sandblasting:

- Capex: Low. Entry-level rigs are $1k–$5k. Industrial blast rooms $10k–$25k.

- Opex: High. Media, PPE, compressor energy, cleanup, and waste disposal costs accumulate. A single large project may consume tons of abrasive.

- Laser:

- Capex: High. $2k–$100k+ depending on power, portability, and automation.

- Opex: Very low. No abrasives, no chemical waste, minimal maintenance, electricity only.

- Practical Example: A small fabrication shop with intermittent needs saves money with blasting. A Tier 1 aerospace supplier saves more long-term with laser by avoiding consumables and compliance costs.

Safety and Compliance Posture

- Sandblasting:

- Dust, noise, and rebound hazards require respirators, hearing protection, blast suits, and strict OSHA compliance.

- Long-term risks include silicosis, lung disease, and hearing loss.

- Laser:

- Reduces dust and noise exposure but introduces laser radiation hazards.

- Requires eye protection, safety interlocks, and controlled zones.

- Easier to align with modern regulatory frameworks, especially where abrasive blasting is restricted.

- Practical Example: Shipyards still rely on blasting (PPE-heavy). Cleanrooms in electronics manufacturing adopt lasers because blasting isn’t even an option.

Choosing the Right Method

When to Choose Laser Rust Removal

High-Value or Sensitive Components

- Examples: turbine blades, aerospace alloys, automotive engine parts, precision molds, stainless steel surgical tools.

- Why Laser: Preserves exact tolerances; no abrasive erosion or foreign particle embedding.

Industries with Strict Environmental or Safety Standards

- Examples: nuclear decontamination, aerospace maintenance under FAA/EASA rules, pharmaceutical or food-grade equipment.

- Why Laser: Generates no abrasive waste, aligns with ISO 14001 environmental standards, and minimizes hazardous exposure.

Automation and Industrial Integration

- Examples: automotive assembly lines, robotic cleaning stations, semiconductor manufacturing.

- Why Laser: Can be programmed into robotic arms or CNC systems for consistent, automated cleaning, improving throughput and repeatability.

Materials Sensitive to Abrasives or Contamination

- Examples: thin aluminum panels, copper busbars, titanium aerospace parts.

- Why Laser: Avoids micro-cracking, thinning, or chloride contamination from blasting media.

Long-Term Cost Efficiency

- Context: High capex ($3k–$50k+), but very low opex (no abrasives, minimal maintenance).

- Why Laser: For frequent or continuous use, ROI is achieved in 2–4 years, especially when compliance costs for blasting are factored in.

When to Choose Sandblasting

Heavy Rust and Large-Scale Surfaces

- Examples: ship hulls, offshore rigs, bridges, industrial tanks, structural beams.

- Why Sandblasting: Can remove mill scale, deep pits, and layered corrosion rapidly over thousands of square meters.

Coating Systems Requiring Mechanical Anchor Profile

- Examples: oil & gas pipelines, protective epoxies on offshore platforms, industrial primers.

- Why Sandblasting: Creates a uniform surface roughness (anchor profile) that coatings mechanically lock into; often required by SSPC, NACE, or ISO standards.

Budget-Conscious Projects

- Context: Portable blasting rigs cost $1k–$5k; industrial blast booths $10k–$25k.

- Why Sandblasting: Lower upfront investment makes it accessible to small shops and contractors. Consumable costs are manageable for intermittent or one-off projects.

Field Operations and Portability

- Examples: bridge repair crews, field weld prep, oil rig maintenance.

- Why Sandblasting: Equipment is rugged, mobile, and usable in remote locations with compressed air access. Laser cleaning systems often require stable electricity and controlled conditions.

Summary

Get Laser Rust Removal Solutions

Drawing upon years of deep expertise in industrial laser cutting, welding, marking, and cleaning, this article presents information based on practical experience and the latest industry insights. By providing clear and technically sound guidance, it helps readers select the right machines, understand process trade-offs, and optimize workflows.

My goal is to help engineers, shop floor managers, and production decision-makers make informed choices that perfectly combine innovation, quality, and operational efficiency.

Drawing upon years of deep expertise in industrial laser cutting, welding, marking, and cleaning, this article presents information based on practical experience and the latest industry insights. By providing clear and technically sound guidance, it helps readers select the right machines, understand process trade-offs, and optimize workflows.

My goal is to help engineers, shop floor managers, and production decision-makers make informed choices that perfectly combine innovation, quality, and operational efficiency.