Understanding Laser Marking

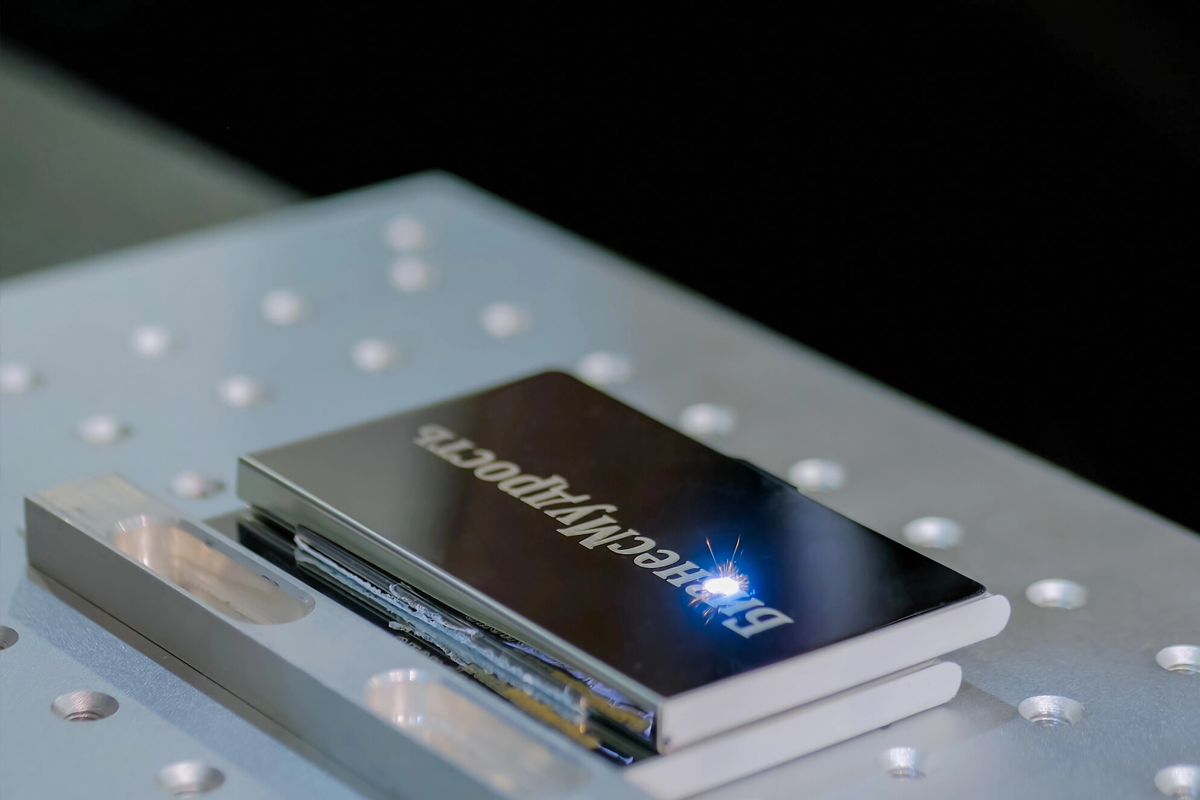

How It Works

Types of Laser Marking

There are several types of laser marking techniques, each suited for different applications:

- Laser Engraving: This method uses a high-power laser to remove material from the surface, creating deep, permanent markings. Laser engraving is ideal for materials like metals and plastics, where a more substantial and durable mark is required.

- Laser Etching: In contrast to engraving, laser etching creates shallow marks on the surface of materials without significantly altering their thickness. It is suitable for creating fine, detailed designs and patterns.

- Laser Ablation: This technique involves removing a thin layer of material, leaving behind a contrasting mark. Laser ablation is commonly used for materials like paints, coatings, and plastics, where the laser removes the top layer to expose a different color or texture beneath.

- Laser Annealing: Used primarily on metals, laser annealing alters the material’s surface color without removing any material. It is typically employed for creating readable text or barcodes, where precision and contrast are essential.

Applicable Materials

Laser marking is highly versatile, as it can be used on a wide array of materials. Some common materials that can be marked using laser technology include:

- Metals: Stainless steel, aluminum, titanium, and brass.

- Plastics: Polycarbonate, ABS, acrylic, and nylon.

- Ceramics and Glass: Laser marking is used to create precise designs on glass and ceramic products.

- Wood: Wood surfaces can be engraved or etched to create intricate designs.

- Leather and Textiles: Although less common, lasers can also mark leather and certain fabrics with high precision.

Advantages of Laser Marking

- Precision and Detail: Laser marking offers unparalleled precision, allowing for the creation of extremely detailed and intricate designs. This is particularly useful for marking small components or products that require fine text, serial numbers, or barcodes.

- Durability and Longevity: The markings produced by lasers are permanent and highly resistant to fading, corrosion, and wear. This makes laser marking ideal for products that need to withstand harsh environments, such as industrial equipment and medical devices.

- Non-Contact Process: Because the laser marking process doesn’t involve direct contact with the material, there is no risk of damaging delicate surfaces or introducing contamination. This also reduces wear and tear on the equipment.

- Environmentally Friendly: Laser marking does not require consumables such as inks, solvents, or chemicals, which reduces waste and environmental impact.

- High-Speed and Efficiency: Modern laser marking systems are highly efficient, capable of producing high-quality marks at relatively high speeds, which is beneficial for high-volume production.

Disadvantages of Laser Marking

- Initial Cost: The setup and equipment for laser marking can be expensive, particularly for high-end laser systems. This can be a barrier for small businesses or those with limited budgets.

- Material Limitations: Not all materials are suitable for laser marking. For instance, certain types of plastics may not produce clear marks, and highly reflective metals can be difficult to mark without specialized equipment.

- Speed for Large Batches: While laser marking is fast for small to medium-sized runs, it can be slower than other techniques, such as screen printing, for very large production volumes.

- Maintenance Costs: The laser equipment requires regular maintenance, including lens cleaning and calibration, which can add to the operational costs.

Applications of Laser Marking

Laser marking is widely used across various industries for a variety of applications:

- Electronics: Laser marking is used to engrave barcodes, serial numbers, and logos on electronic components like circuit boards, smartphones, and computer parts. This ensures that the markings remain legible over time despite exposure to heat and wear.

- Automotive: In the automotive industry, laser marking is used for marking engine components, chassis parts, and identification numbers. This provides traceability and compliance with regulations, ensuring parts are easily identifiable.

- Medical Devices: Laser marking is crucial in the medical device industry, where permanent, readable markings are necessary for product identification, regulatory compliance, and traceability of surgical instruments, implants, and packaging.

- Aerospace: Aerospace manufacturers use laser marking to ensure that critical parts, such as aircraft components and engine parts, are marked with serial numbers, part identifiers, and logos, which must withstand extreme environmental conditions.

- Consumer Goods: Laser marking is increasingly used in the production of personalized items, such as engraved jewelry, watches, and promotional products. The ability to create high-quality, intricate designs on a variety of materials makes it popular for customization.

- Packaging: In the packaging industry, lasers are used for creating date codes, batch numbers, and logos on products such as food packaging and pharmaceuticals, ensuring that the information is permanent and resistant to wear.

Understanding Screen Printing

How It Works

Types of Screen Printing

Screen printing comes in several variations, each suited for different applications:

- Manual Screen Printing: This method is often used for small runs or custom printing. The operator manually positions the screen and uses a squeegee to apply ink. While more labor-intensive, manual printing allows for flexibility and creativity in custom jobs.

- Automated (or Mechanical) Screen Printing: In this process, machines automate the screen printing process, allowing for faster and more consistent prints. This method is ideal for mass production, as it can handle large quantities of prints efficiently.

- Multi-Color Screen Printing: This technique uses multiple screens to apply different colors to the same surface. Each screen is dedicated to a specific color, and the process is repeated for each layer, resulting in a final multi-colored design. The challenge lies in aligning the screens correctly to achieve precise, vibrant results.

- Flatbed vs. Rotary Screen Printing:

- Flatbed Screen Printing: The substrate (material to be printed) remains stationary while the screen moves, typically used for items like posters or small garments.

- Rotary Screen Printing: This version uses a cylindrical screen that rotates, making it ideal for continuous, high-speed printing on large surfaces, like fabrics or wallpaper.

Applicable Materials

Screen printing is highly versatile in terms of the materials it can print on, making it a popular choice for various industries. Some of the most common materials include:

- Textiles: T-shirts, hoodies, and other apparel items are among the most common uses for screen printing, thanks to its ability to create bold, vibrant designs.

- Paper and Cardboard: Often used for printing posters, flyers, and packaging.

- Plastics: Used for promotional items, signage, and packaging.

- Metal: Screen printing is used for industrial applications, such as printing on aluminum panels, electronic circuit boards, or metal containers.

- Glass: Screen printing is commonly used to print on glass for items like bottles, windows, and decorative glass products.

- Wood: For custom woodworking, furniture, or decorative items.

Advantages of Screen Printing

- Cost-Effective for Large Runs: One of the most significant advantages of screen printing is its cost-effectiveness for large production runs. The cost per unit decreases as the volume increases, making it an ideal choice for mass production.

- Durability: The ink used in screen printing is thick and adheres well to materials, creating long-lasting, resistant prints. It is highly durable, especially on textiles and promotional items, and can withstand wear, weather, and washing.

- Vibrant Colors: Screen printing uses thick ink layers, which result in bright, vibrant colors that stand out, making it a popular choice for high-impact designs.

- Versatility: Screen printing can be done on a variety of materials and can print on irregular shapes and surfaces, such as bottles, fabrics, and even cylindrical items.

- Low Setup Cost for Short Runs: The initial setup cost is relatively low for screen printing, making it ideal for small batches and custom designs, especially with manual screen printing setups.

- Multiple Color Capabilities: With multiple screens, the screen printing process can produce multi-colored designs, which is great for intricate or detailed artwork.

Disadvantages of Screen Printing

- Setup Time and Costs for Small Runs: While screen printing is efficient for large batches, the setup time and costs can be high for smaller production runs. The process requires preparing individual screens for each color and creating stencils, which can be time-consuming and expensive.

- Limited Detail and Precision: Although screen printing is excellent for bold and vibrant designs, it struggles with fine details, especially when dealing with small text or intricate patterns. It is not suitable for micro-level precision as compared to laser marking.

- Environmental Impact: The use of inks, solvents, and chemicals in screen printing can be harmful to the environment, though eco-friendly inks are becoming more common. Additionally, the process generates waste in the form of ink, emulsions, and screens.

- Limited to Flat or Slightly Curved Surfaces: While screen printing is versatile, it’s not always suitable for highly irregular or three-dimensional objects. The process is optimized for flat or gently curved surfaces, such as fabric or flat metal.

- Ink Drying Time: Depending on the type of ink used, drying or curing the ink can take time. While some inks require heat curing, others may take time to air dry, which can slow down production.

Applications of Screen Printing

Screen printing is widely used across multiple industries for a variety of applications:

- Textiles and Apparel: Screen printing is most famously used in the garment industry, where it is the primary method for printing t-shirts, hoodies, and custom clothing. It’s ideal for producing bold, colorful designs on fabric.

- Advertising and Signage: Large-scale posters, banners, and promotional signage are often produced using screen printing. Its ability to print vibrant colors on large surfaces makes it a go-to method for the advertising industry.

- Packaging: Screen printing is used to print labels and graphics on product packaging, especially for bottles, cans, and boxes. The thick ink adheres well to materials like plastic and glass, ensuring that the print remains intact during handling.

- Electronics: In the electronics industry, screen printing is used for printing circuit boards, keypads, and various other components. The process allows for precise and durable prints on materials like plastic and metal.

- Promotional Products: Many companies use screen printing for custom promotional products, such as tote bags, drinkware, and pens. These products often feature company logos and slogans in vibrant, eye-catching colors.

- Home Decor and Art: Artists and home décor manufacturers use screen printing to create prints on various substrates like canvas, wood, and glass. The technique allows for high-quality, reproducible artwork.

Comparison Between Laser Marking and Screen Printing

Substrate Considerations

- Laser Marking: Laser marking excels in marking a wide variety of materials, including metals (stainless steel, aluminum, titanium), plastics (ABS, polycarbonate, acrylic), ceramics, glass, wood, and even leather. The ability to work with both hard and soft materials makes it highly versatile. However, certain highly reflective or transparent materials can present challenges, requiring specialized equipment.

- Screen Printing: Screen printing is similarly versatile in terms of substrates but is most commonly used for flat or slightly curved surfaces. Common materials include textiles (cotton, polyester), paper, cardboard, plastics (PET, PVC), glass, and metal. It’s particularly popular for large, flexible items like fabric or packaging. The primary limitation is on highly irregular or three-dimensional surfaces, where achieving even results may be difficult.

Precision and Quality

- Laser Marking: One of the standout features of laser marking is its high precision. Lasers can achieve micron-level accuracy, making it ideal for fine details such as serial numbers, logos, barcodes, and intricate patterns. Laser marking is especially well-suited for small, highly detailed designs on both large and small-scale applications.

- Screen Printing: While screen printing can produce high-quality prints with bold, vibrant colors, its precision is limited compared to laser marking. Fine details, small text, and intricate designs may not reproduce as well, especially when multiple colors are involved. The technique is better suited for larger, simpler designs rather than micro-level text or graphics.

Speed and Efficiency

- Laser Marking: Laser marking is generally fast for small to medium-sized production runs due to its non-contact, automated nature. However, when it comes to very high-volume jobs, laser marking can be slower than screen printing, especially for larger designs that require high-precision engraving. The speed can also vary depending on the material and complexity of the mark.

- Screen Printing: Screen printing shines in high-volume production runs. Once the screens are prepared, the printing process is fast, and it can handle large quantities of prints in a short period. Automated screen printing machines can produce thousands of units per hour, making them highly efficient for mass production. However, it may take longer to set up for multi-color designs or when printing on irregular surfaces.

Cost Analysis

- Laser Marking: Laser marking systems often come with a higher initial investment, particularly for high-powered or high-precision lasers. Additionally, the ongoing operational costs tend to be lower as there are no consumables like ink, and maintenance mainly involves servicing the laser equipment. However, for low-volume jobs or small businesses, the initial investment can be a significant barrier.

- Screen Printing: The initial setup costs for screen printing are generally lower than for laser marking, especially for manual setups. However, the cost of consumables (inks, screens, emulsions) and the need for regular maintenance and replacement parts can add up over time. Additionally, screen printing becomes more cost-effective with larger batches, as the per-unit cost decreases with increased volume.

Environmental Impact

- Laser Marking: Laser marking is considered an environmentally friendly option due to its non-contact, non-chemical nature. There are no inks, solvents, or chemicals involved in the process, which reduces waste. The process generates minimal waste, with the only byproduct being vaporized material, which can be safely managed with proper ventilation. Additionally, laser equipment typically has a long lifespan, contributing to sustainability.

- Screen Printing: Screen printing has a greater environmental impact due to the use of inks, solvents, and chemicals that can produce waste and require disposal. Some inks contain harmful chemicals, though there are eco-friendly alternatives available, such as water-based inks. The screen printing process also generates waste in the form of screens, emulsions, and cleaning solvents. However, advancements in sustainable printing practices are making it more eco-friendly.

Durability of Markings

- Laser Marking: The marks produced by laser technology are highly durable, as they are etched or engraved into the material. Laser markings are resistant to wear, fading, corrosion, and environmental factors, making them ideal for products that are exposed to harsh conditions, such as automotive parts, medical devices, and electronics. The permanence of laser marks ensures they remain legible over time.

- Screen Printing: Screen printing creates durable marks, especially when high-quality inks are used. Prints on textiles, for example, can withstand multiple washes without fading. However, compared to laser markings, screen-printed designs may eventually wear off, especially if exposed to harsh environmental conditions, such as abrasion, extreme heat, or chemicals. The durability of the print largely depends on the type of ink and material used.

Safety Considerations

- Laser Marking: While laser marking is a non-contact process, it does involve high-powered lasers that can be hazardous if not handled properly. Lasers can cause eye injury, burns, or other accidents if safety protocols aren’t followed. For this reason, protective gear such as safety goggles, proper ventilation, and enclosed work areas are essential for operators.

- Screen Printing: The safety concerns in screen printing are more related to the chemicals used, such as inks and solvents, which can be hazardous if inhaled or ingested. Prolonged exposure to these substances may lead to respiratory issues or skin irritation. Proper ventilation and protective equipment (gloves, masks) are necessary when working with these materials.

Integrating Technology and Automation

- Laser Marking: Laser marking systems are highly automated and integrate well with other technologies such as robotics, conveyor systems, and industrial automation setups. This makes it easy to incorporate laser marking into a modern production line, particularly for high-precision tasks like engraving barcodes, QR codes, and serial numbers.

- Screen Printing: While screen printing has traditionally been a manual process, modern automated screen printing machines have greatly improved efficiency and precision. Automated systems can handle high-volume production and multi-color prints, but they may still require more hands-on involvement for setup and maintenance compared to laser marking.

Design Flexibility and Aesthetics

- Laser Marking: Laser marking offers exceptional precision and can produce intricate designs, including text, logos, and detailed artwork. It is perfect for creating high-resolution, permanent designs on small surfaces. However, its ability to produce color is limited, typically resulting in monochrome designs. While it’s great for industrial or functional markings, it may not always be ideal for vibrant, multi-colored designs.

- Screen Printing: Screen printing excels in producing vibrant, multi-colored designs, making it ideal for artistic and promotional applications. It offers great flexibility in terms of color and texture, allowing for bold, eye-catching prints. The downside is that achieving fine details or gradients can be challenging, and screen printing is best suited for larger or less intricate designs.

How to Choose: Laser Marking or Screen Printing

Choose Laser Marking If

- You Need High Precision and Detail: Laser marking is ideal if your project requires fine, intricate designs, such as serial numbers, QR codes, barcodes, or small logos. The precision of laser marking allows you to create highly detailed and clear marks, which are difficult to achieve with screen printing.

- You Require Permanent, Durable Marks: If your products need to withstand harsh conditions, such as exposure to chemicals, abrasions, extreme temperatures, or outdoor environments, laser marking is a superior choice. The marks created by lasers are permanent and highly resistant to wear, corrosion, or fading over time, making them ideal for applications in industries like aerospace, automotive, and medical devices.

- You Are Marking Small or Intricate Items: Laser marking works best for small, compact items or components where space is limited. The process allows for fine detail even on tiny surfaces, which makes it suitable for products like electronics, jewelry, tools, and medical devices that require precision marking.

- You Want a Non-Contact, Environmentally Friendly Process: Since laser marking doesn’t use inks, solvents, or chemicals, it produces minimal waste and is considered an environmentally friendly solution. If sustainability is a priority for your business, laser marking can help you reduce your environmental footprint.

- You Have Low to Medium Production Volumes: While the initial investment for laser marking equipment can be high, the process is efficient for small to medium production runs. Laser marking systems are automated, which helps reduce labor costs and increases consistency, making it a suitable choice for companies that need precision without high-volume production.

- You Need a High Level of Automation: If your production process is automated or you require integration with other automated systems, laser marking is an excellent choice. Laser systems can be easily incorporated into robotic, conveyor, or other automated production lines, providing a seamless, high-speed operation with minimal operator intervention.

Choose Screen Printing If

- You Are Producing Large Volume Runs: Screen printing is particularly cost-effective for large-scale production runs. Once the screens are created, the process is relatively fast and efficient, allowing you to produce thousands of units with minimal setup time. This makes screen printing ideal for bulk production, such as t-shirts, posters, or packaging.

- You Need Bold, Vibrant Designs or Multi-Color Prints: If your project requires bold, multi-colored designs, screen printing is a better option. It allows you to print vibrant colors and large designs on a variety of materials. The process can easily handle multiple layers of ink to create bright, eye-catching graphics, which makes it perfect for applications like promotional materials, apparel, and signage.

- You Are Printing on Fabric, Textiles, or Flexible Materials: Screen printing is especially effective on textiles such as t-shirts, hoodies, and other apparel. The process is also suitable for printing on flexible materials like paper, plastic, and cardboard. If your business focuses on producing clothing, custom fabric items, or promotional products, screen printing is the go-to method for large, colorful designs.

- You Have a Lower Initial Budget: Compared to laser marking, the initial investment for screen printing equipment is typically lower, especially for small or manual setups. If you’re a small business or working with a limited budget, screen printing allows you to produce high-quality prints without the high upfront costs associated with laser systems.

- You Need to Print on Irregular or Large Surfaces: Screen printing can be used to print on large or irregularly shaped surfaces, such as promotional items like drinkware, bags, or posters. It is also effective for printing on flat, slightly curved, or cylindrical objects, which can be challenging for laser marking.

- You Want Simplicity and Speed for Large Orders: For businesses that require fast turnaround times and large quantities, screen printing is the better option. With automated systems, the printing process can be streamlined to handle high-volume orders with quick setup and production times, making it ideal for bulk jobs.

Summary

Get Laser Marking Solutions

Drawing upon years of deep expertise in industrial laser cutting, welding, marking, and cleaning, this article presents information based on practical experience and the latest industry insights. By providing clear and technically sound guidance, it helps readers select the right machines, understand process trade-offs, and optimize workflows.

My goal is to help engineers, shop floor managers, and production decision-makers make informed choices that perfectly combine innovation, quality, and operational efficiency.

Drawing upon years of deep expertise in industrial laser cutting, welding, marking, and cleaning, this article presents information based on practical experience and the latest industry insights. By providing clear and technically sound guidance, it helps readers select the right machines, understand process trade-offs, and optimize workflows.

My goal is to help engineers, shop floor managers, and production decision-makers make informed choices that perfectly combine innovation, quality, and operational efficiency.