Product Introduction

Types of CO2 Laser Marking Machines

-

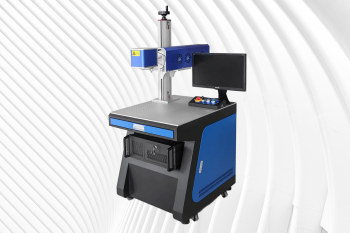

FM-CD Laser Marking Machine

Rated 4.75 out of 5$4,290.00 – $23,920.00Price range: $4,290.00 through $23,920.00 Select options This product has multiple variants. The options may be chosen on the product page -

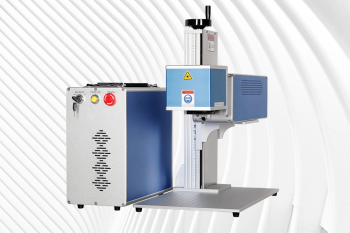

FM-CH Laser Marking Machine

Rated 4.63 out of 5$4,680.00 – $24,310.00Price range: $4,680.00 through $24,310.00 Select options This product has multiple variants. The options may be chosen on the product page -

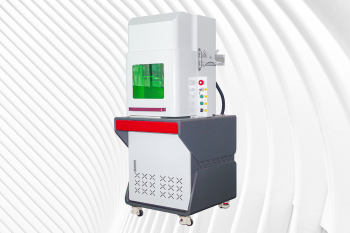

FM-CS Laser Marking Machine

Rated 4.88 out of 5$4,420.00 – $24,050.00Price range: $4,420.00 through $24,050.00 Select options This product has multiple variants. The options may be chosen on the product page -

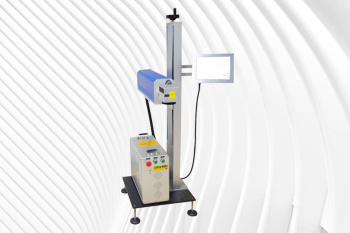

FM-CP Laser Marking Machine

Rated 4.75 out of 5$4,550.00 – $24,180.00Price range: $4,550.00 through $24,180.00 Select options This product has multiple variants. The options may be chosen on the product page -

FM-CE Laser Marking Machine

Rated 4.88 out of 5$5,590.00 – $25,220.00Price range: $5,590.00 through $25,220.00 Select options This product has multiple variants. The options may be chosen on the product page -

FM-CF Laser Marking Machine

Rated 4.50 out of 5$6,370.00 – $26,000.00Price range: $6,370.00 through $26,000.00 Select options This product has multiple variants. The options may be chosen on the product page

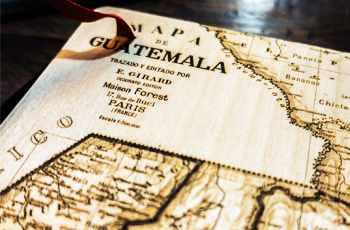

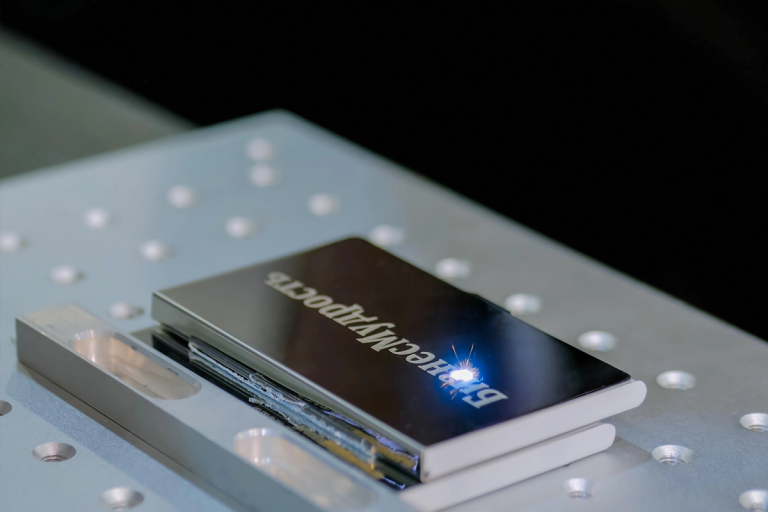

Application of CO2 Laser Marking Machines

Why Choose Us

Precision Engineering

Our machines deliver ultra-fine marking and engraving with high-speed galvanometer systems and stable laser sources for consistent, reliable output.

Wide Material Compatibility

We offer different laser types to match your needs, ensuring crisp, permanent marks on metal, plastic, wood, leather, and more.

User-Friendly Software

Intuitive control software allows easy setup, flexible design import, and precise marking even for first-time users.

Customizable Solutions

We provide machine options tailored to your product size, line speed, and marking content for seamless integration.

Low Maintenance

Our systems run cleanly with no inks or chemicals, lowering long-term operating costs and environmental impact.

Dedicated Support and Service

Faster Laser offers professional training, remote troubleshooting, and responsive service to keep your production running smoothly.

CO2 Laser Marking Machines VS Other Marking Machines

| Comparison Item | CO2 Laser Marking Machine | Dot Peen Marking Machine | Inkjet Printing Machine | Stamping Machine |

|---|---|---|---|---|

| Marking Method | Focused CO2 laser beam | Mechanical pin strikes surface | Ink droplets sprayed onto material | Mechanical die impact |

| Contact or Non-Contact | Non-contact | Contact-based | Non-contact | Contact-based |

| Marking Speed | Fast | Moderate | Very fast | Fast |

| Marking Precision | High (fine detail and edges) | Moderate | Moderate | Low to moderate |

| Suitable Materials | Wood, leather, acrylic, plastic, rubber, paper | Mainly metals | Paper, plastic, some coated materials | Metals and rigid materials |

| Surface Damage Risk | None | Medium (indentation) | None | High |

| Maintenance Requirements | Low | Moderate | High (clogs, ink refills) | High (tool wear, alignment) |

| Operating Cost | Low (no consumables) | Low | High (consumables, ink) | Moderate (tooling costs) |

| Marking Durability | Permanent on non-metals | Permanent on metals | Temporary (can fade or rub off) | Permanent on suitable materials |

| Environmental Impact | Low (no inks or solvents) | Low | High (ink waste, VOCs) | Moderate (material waste) |

| Setup Time | Short | Moderate | Short | Long (custom die setup) |

| Flexibility (Text, Codes, Logos) | High (supports complex designs) | Limited to basic text | High | Low |

| Noise Level | Low | High (mechanical impact) | Low | High |

| Automation Capability | Excellent (easily integrates with conveyors) | Limited | Good | Limited |

| Common Applications | Packaging, signage, plastics, wood, rubber | Nameplates, metal parts | Consumer goods, packaging | Heavy metal parts, branding |

Customer Testimonials

Related Resources

Laser Marking VS Screen Printing

This article explores the key differences between laser marking and screen printing, comparing their processes, advantages, disadvantages, applications, and how to choose the right method for your needs.

Frequently Asked Questions

What is CO2 Laser Marking?

What Laser Power Options Are Available For CO2 Laser Marking Machines?

- 30W CO2 Laser Marking Machines: Ideal for light-duty applications where high precision and speed are needed on thin materials. These machines work well with paper, cardboard, thin plastics, and coated labels. They are commonly used in packaging industries for date codes, serial numbers, and logos, but may not achieve sufficient depth on harder or thicker materials.

- 60W CO2 Laser Marking Machines: A more versatile choice for medium-duty marking tasks. These systems can effectively mark wood, leather, acrylic, rubber, and glass surfaces. 60W provides a good balance between marking speed and depth, making it suitable for customized gifts, signage, leather branding, and product traceability across a wide range of industries.

- 100W CO2 Laser Marking Machines: Designed for more demanding applications that require deeper engraving or faster throughput. These machines are suitable for marking dense woods, thick acrylics, and multilayer plastics. They are often found in industrial environments where durability, clarity, and efficiency are essential.

- 150W CO2 Laser Marking Machines: The most powerful standard configuration, 150W machines are used for high-speed, deep engraving, and high-volume production environments. They handle thick, tough, or heat-resistant materials such as rubber, hard plastics, and engineered foams. These systems are ideal for large-scale manufacturing, signage, and cutting/engraving hybrid tasks.

What Is The Price Of CO2 Laser Marking Machines?

- 30W CO2 Laser Marking Machines: These entry-level systems are ideal for marking light-duty materials such as paper, leather, thin plastics, and packaging labels. Prices usually range from $4,500 to $7,000. They are cost-effective for small businesses or custom engraving shops and offer good marking speed for soft materials.

- 60W CO2 Laser Marking Machines: With moderate power, 60W machines are more versatile and suitable for materials like acrylic, wood, ABS, and rubber. They typically cost between $7,000 and $12,000. These machines strike a balance between affordability and capability, making them popular in mid-scale production environments.

- 100W CO2 Laser Marking Machines: Designed for deeper or faster marking of thicker materials such as dense wood, layered plastics, and engraved signage, these systems range from $12,000 to $20,000. They are well-suited for industries that require consistent, high-speed output and can also handle larger marking areas.

- 150W CO2 Laser Marking Machines: High-performance systems for industrial use, capable of marking hard or thick materials like rubber sheets, thick foam, and engineered plastics. Their price ranges from $20,000 to $30,000, depending on features such as fume extraction, automation compatibility, and enclosure design.

What Materials Can Be Marked With CO2 lasers?

- Wood and Wood-Based Products: CO2 lasers mark plywood, MDF, hardwood, softwood, bamboo, and veneer with excellent contrast. The laser burns or engraves the surface, creating dark, precise patterns or text. Common uses include personalized gifts, branding, signage, and craftwork. Proper ventilation is essential due to smoke production.

- Acrylic and Plastics: CO2 lasers provide clean, detailed marks on acrylic (PMMA), ABS, polycarbonate, Delrin, and polyethylene. The beam melts or vaporizes the surface to produce high-contrast marks. However, plastic composition varies, and PVC must never be marked as it releases toxic chlorine gas.

- Paper and Cardboard: Thin, flammable materials like paper, cardstock, chipboard, and cardboard can be marked quickly and cleanly. Ideal for packaging codes, product labels, logos, and decorative designs. These materials require constant monitoring to prevent ignition and benefit from air assist and exhaust systems.

- Leather and Fabrics: Natural leather and many textiles (cotton, polyester, felt, denim) can be marked or engraved with excellent precision. CO2 lasers burn the surface to create contrast, making them ideal for customizing clothing, shoes, bags, and upholstery. Synthetic leathers and vinyls must be verified safe to avoid hazardous emissions.

- Rubber: CO2 lasers mark laser-safe rubber sheets used for stamps, seals, and gaskets. The beam creates precise, durable markings. However, rubbers containing chlorine compounds are unsafe and produce harmful gases when marked.

- Foam: EVA foam, polyethylene foam, and similar materials are often used for inserts, packaging, and crafts. CO2 lasers mark or cut these foams effectively, but supervision is required due to the fire risk and fume generation.

- Glass and Ceramics (Engraving Only): While CO2 lasers cannot cut through glass or ceramic, they can engrave the surface for decorative or branding purposes. The beam causes surface stress that creates frosted or matte finishes. Applications include etched drinkware, tiles, and art pieces.

- Coated or Painted Metals: CO2 lasers cannot mark bare metals effectively, but they can remove paint, anodized coatings, or surface layers to expose the underlying metal for contrast. Useful for part labeling or patterning pre-treated metal surfaces.

What File Formats Are Supported By CO2 Laser Marking Machines?

- Vector Graphics: CO2 lasers use vector files for accurate line work, outlines, and engraving paths. Supported vector formats include DXF, PLT, AI, SVG, and EPS. These formats are ideal for cutting and marking designs that require scalability and sharp edges, such as logos, part outlines, barcodes, and labels.

- Bitmap Images: When working with photo engraving or grayscale shading, CO2 lasers can process raster images in formats such as BMP, JPG, PNG, and GIF. These files are converted into dot or grayscale patterns by the laser software, allowing detailed image reproduction on materials like wood, acrylic, and leather.

- Text and Data Files: For automated marking of serial numbers, batch codes, or variable content, CO2 laser software supports TXT, CSV, and XLS/XLSX formats. These formats allow dynamic data input for high-volume marking tasks in packaging, labeling, and product traceability.

What Are The Disadvantages Of CO2 Laser Marking Machines?

- Limited to Non-Metals: CO2 lasers cannot effectively mark untreated metal surfaces. Their beam, with a wavelength of 10.6 μm, is poorly absorbed by metals like stainless steel or aluminum. This limits their use in industries that require direct marking on bare metal parts, making fiber lasers a better alternative for such applications.

- Toxic Fume Emissions: When marking materials like plastics, leather, rubber, or synthetic fabrics, CO2 lasers can generate hazardous fumes, including VOCs or toxic gases such as chlorine from PVC. This requires the use of advanced fume extraction systems, which add cost and maintenance complexity.

- Lower Precision for Fine Details: Due to the longer wavelength and larger spot size, CO2 lasers are not ideal for micro-marking tasks or ultra-fine detailing. Applications requiring extremely small, sharp marks, such as circuit boards or precision electronics, may be better served by UV or fiber laser systems.

- Cooling Requirements: Higher-powered CO2 laser systems (especially 100W and above) often require water cooling, which increases the overall size, complexity, and maintenance requirements of the machine. Air-cooled systems exist, but they are generally limited to lower-power models.

- Slower on Dense Materials: Compared to fiber lasers, CO2 lasers can be slower when marking high-density or layered materials, especially when deeper engraving is needed. This can affect productivity in industrial environments where marking speed is critical.

- Larger Footprint: CO2 laser systems, particularly those with glass laser tubes, tend to have a bulkier design, requiring more space and offering less portability than compact fiber laser marking systems.

How Long Can CO2 Laser Marking Last?

- Lifespan of CO2 Laser Markings

- On Wood, Leather, and Acrylic: Marks are permanent unless mechanically sanded or cut off. The engraved areas are part of the material surface and will last indefinitely under normal conditions.

- On Plastics (ABS, Acrylic, etc.): Markings made through surface melting or foaming are also long-lasting, especially on indoor products. However, exposure to UV light or harsh chemicals over time may slightly fade the contrast on certain plastics.

- On Coated Metals or Painted Surfaces: CO2 lasers remove the coating or paint layer to expose the base material. These marks remain visible for years, but abrasion or environmental wear could degrade them depending on usage conditions.

- Durability Against Environmental Factors

- Abrasion Resistance: While not as deep as fiber laser engravings on metal, CO2 laser marks on wood, plastic, and coated surfaces are generally resistant to rubbing, scratching, and normal wear.

- Chemical Resistance: CO2 laser marks are not affected by solvents if they are engraved or burned into the material. However, if the marking is superficial (e.g., a color change on the surface), strong cleaning agents may affect contrast over time.

- UV and Weather Resistance: For indoor products, marks last indefinitely. For outdoor items (like signs or labels), UV exposure may eventually fade markings on certain plastics or organic materials unless UV-stabilized materials are used.

What Is The Lifespan Of CO2 Laser Tubes?

- Glass CO2 Laser Tubes: These tubes are widely used in budget-friendly or entry-level systems. They generally last 1,000 to 3,000 hours, depending on the power output, usage intensity, and cooling efficiency. Glass tubes require water cooling and are more fragile due to their sealed-glass structure. Their lifespan can be shortened if operated continuously at maximum power or under poor environmental conditions.

- Metal RF CO2 Laser Tubes: Found in higher-end industrial machines, metal RF (radio frequency) tubes can last 20,000 to 30,000 hours. They are air-cooled, more durable, and maintain consistent beam quality over longer periods. Although more expensive initially, they are ideal for long-term use in production environments with heavy workloads.