Product Introduction

Types of Tube Laser Cutting Machines

-

FT-C Laser Cutting Machine

Rated 4.38 out of 5$29,250.00 – $218,400.00Price range: $29,250.00 through $218,400.00 Select options This product has multiple variants. The options may be chosen on the product page -

FT Laser Cutting Machine

Rated 4.75 out of 5$35,750.00 – $224,900.00Price range: $35,750.00 through $224,900.00 Select options This product has multiple variants. The options may be chosen on the product page -

FT-A Laser Cutting Machine

Rated 5.00 out of 5$94,250.00 – $283,400.00Price range: $94,250.00 through $283,400.00 Select options This product has multiple variants. The options may be chosen on the product page

Application of Tube Laser Cutting Machines

Why Choose Us

Cutting-Edge Technology

Every Faster Laser machine is built with the latest advancements, ensuring precise cuts, faster operation speeds, and the ability to handle complex designs effortlessly.

Superior Build Quality

We use only premium-grade materials and components, ensuring that every machine delivers consistent performance and maintains durability under heavy use.

Customized Solutions

Our team works closely with each customer to develop tailored laser cutting solutions that meet specific production needs and business objectives.

Comprehensive Support

Faster Laser provides thorough training, responsive technical support, and ongoing maintenance services to keep your machines running at peak efficiency.

Cost-Effective Investment

We offer high-quality laser cutting machines at competitive prices, ensuring you get maximum performance and long-term value from your investment.

Proven Industry Experience

With years of expertise and a strong global client base, Faster Laser has built a reputation for reliability, innovation, and customer satisfaction.

Tube Laser Cutting Machines VS Other Cutting Machines

| Comparison Item | Tube Laser Cutting Machine | Plasma Cutting Machine | Waterjet Cutting Machine | Flame Cutting Machine |

|---|---|---|---|---|

| Cutting Method | Fiber laser beam | Ionized gas arc | High-pressure water with abrasive | Oxy-fuel combustion |

| Tube Cutting Capability | Built-in rotary system for all tube shapes | Not designed for tubes (manual setup needed) | Limited, requires complex fixtures | Not suitable for round or shaped tubes |

| Cutting Precision | Very high | Moderate | High | Low |

| Edge Quality | Clean, smooth, burr-free | Rough, often needs finishing | Smooth, minimal burring | Rough and oxidized |

| Cutting Speed | Fast | Fast | Slow to moderate | Slow |

| Hole and Slot Cutting | Precise and consistent | Inconsistent on round surfaces | Possible but slow | Difficult and inaccurate |

| Bevel and Angle Cutting | Automated, accurate | Possible but limited | Difficult and time-consuming | Very limited |

| Material Compatibility | Metals: SS, CS, aluminum, brass, copper | Conductive metals only | Most materials | Carbon steel only |

| Heat Affected Zone (HAZ) | Very small | Medium | None | Large |

| Automation & CNC Integration | Excellent | Good | Limited | Poor |

| Repeatability | High | Moderate | High | Low |

| Maintenance Requirements | Low | Moderate | High | Low |

| Operating Cost | Low | Moderate | High (abrasives, water use) | Low |

| Setup Time | Fast, automated | Manual alignment required | Long setup time | Manual and slow |

| Typical Industry Applications | Fitness, auto parts, furniture, structures | General metal cutting | Aerospace, prototyping | Heavy industrial, structural steel |

Customer Testimonials

Related Resources

Laser Cutting VS Waterjet Cutting

This article compares laser cutting and waterjet cutting, covering processes, materials, costs, precision, and applications to help manufacturers select the best method.

Laser Cutting VS Plasma Cutting

This article explores a detailed comparison of laser cutting and plasma cutting, including how each process works, material ranges, cut quality, speed, costs, safety, and key selection factors.

Frequently Asked Questions

What is Tube Laser Cutting?

What Is The Price Of Tube Laser Cutting Machines?

- Economic Tube Laser Cutting Machines ($30,000 – $250,000): These budget-friendly models feature basic rotary chucks, suitable for cutting round, square, and rectangular pipes with manual loading. They usually have 1kW–3kW laser power and are ideal for small to mid-size workshops. While they offer reliable performance, they may lack speed, automation, or advanced beveling capabilities.

- Standard Tube Laser Cutting Machines ($40,000 – $260,000): These machines strike a balance between cost and performance, featuring servo-driven chucks, pneumatic clamping systems, and support for both small and large tube diameters. They typically offer 3kW–6kW fiber laser power and support auto-focus heads, nesting software, and moderate automation. Suitable for general metal fabrication, furniture, and mechanical parts production.

- Automatic Loading and Unloading Tube Laser Cutting Machines ($100,000 – $300,000): High-end models are designed for industrial-scale production. These machines feature fully automated feeding systems, unloading conveyors, tube storage racks, and advanced sensors to handle high-speed continuous operations. Ideal for factories needing to process large volumes of pipes with minimal manual intervention, especially in automotive, construction, or fitness equipment manufacturing.

What Is The Maximum Tube Diameter That Tube Laser Cutting Machines Can Cut?

- Small to Medium Tubes (20–160 mm): Most standard tube laser cutting machines can handle round, square, and rectangular tubes starting from as small as 20 mm in diameter, with a maximum of 160 mm. This range is common in applications like metal furniture, automotive frames, exercise equipment, and small mechanical parts.

- Large Tubes (160–220 mm): Many mid- to high-end machines support tubes up to 220 mm in diameter. These machines are ideal for structural supports, handrails, agricultural implements, and industrial enclosures. Larger chuck sizes and reinforced support rollers are used to handle the additional weight and dimensions.

- Extra-Large Tubes (220–300 mm or more): Advanced or customized tube laser cutting machines can process tubes up to 300 mm or even 350 mm in diameter. These are used in construction steel, shipbuilding, oil & gas pipelines, and steel structure fabrication, where thick-walled and large-diameter pipes are common.

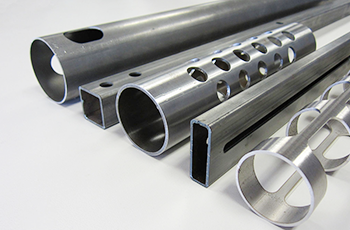

What Shapes Of Tubes Can Tube Laser Cutting Machines Cut?

- Round Tubes: The most common tube shape processed by laser cutting machines. Round tubes are used in furniture, automotive exhaust systems, scaffolding, fitness equipment, and fluid transport pipelines. Tube laser machines can perform straight cuts, angled cuts, perforations, and fish-mouth joints for round pipes with high precision.

- Square Tubes: Frequently used in structural frames, metal furniture, and industrial supports, square tubes allow for clean slots, notches, and interlocking joints. Laser machines can easily rotate and position square tubing to create bevel cuts, tab connections, or customized openings.

- Rectangular Tubes: Ideal for chassis, display racks, and support structures, rectangular tubes benefit from the tube laser’s ability to adjust cutting angles and edge designs, even when multiple holes or cutouts are needed across different sides of the profile.

- Oval and Elliptical Tubes: These are commonly found in bicycle frames, railings, and decorative elements. Tube laser machines can adjust their motion and chuck systems to rotate and align non-circular profiles for precise and symmetrical cutting patterns.

- D-Shaped and Flat-Sided Tubes: Custom or semi-flat profiles like D-tubes are used in automotive, aerospace, and ergonomic product design. These can be cut with specialized support and software to accommodate the irregular cross-section.

- Angle Iron and C-Channels: Some advanced tube laser cutting machines can also process L-shaped (angle iron), U-shaped (channels), and T-profile sections. These shapes are used in modular steel frames, construction supports, and shelving systems. The laser system must be equipped with enhanced fixturing and profile tracking to handle open or uneven profiles.

How Do Tube Laser Cutting Machines Work?

- Tube Loading and Clamping: Tube laser cutting begins with loading the pipe onto the machine’s support bed. Depending on the model, this may be done manually or via an automatic loading system. The tube is then securely clamped by a pneumatic or servo-controlled rotary chuck, which allows the tube to rotate during cutting for full 360° access.

- Tube Rotation and Movement: The machine’s control system rotates the tube and feeds it forward and backward along its axis. This multi-axis motion enables the laser to cut not only straight edges but also holes, slots, bevels, and complex interlocking shapes on all sides of the tube.

- Laser Cutting Process: A fiber laser beam, focused through a cutting head, melts or vaporizes the metal surface. Assist gas, such as oxygen, nitrogen, or air, is used to blow away molten material, producing smooth edges. The laser and gas settings are automatically adjusted according to the tube’s material type and thickness.

- Profile Recognition and Precision Cutting: Advanced systems include weld seam detection, auto-centering chucks, and profile-following sensors to ensure that cuts are aligned correctly, even on non-round or irregular tube profiles. This enables complex parts to be fabricated with high repeatability.

- Finished Part Unloading: Once the cutting job is complete, the finished tube sections are either manually removed or automatically discharged onto an unloading rack or conveyor. Scrap is dropped into a separate bin to keep the machine area clean and efficient.

How To Maintain Tube Laser Cutting Machines?

- Daily Maintenance

- Clean the Rotary Chuck and Support Rollers: Dust, slag, and fine metal particles can accumulate around the rotating chuck and pipe support areas. Wipe down surfaces and ensure the chuck moves smoothly without vibration. Check that the rollers supporting long tubes are clean and roll freely.

- Inspect and Clean the Protective Lens and Nozzle: Check the protective lens for smoke stains or spatter. Clean it gently with lens paper and isopropyl alcohol. Inspect the nozzle for blockage or deformation, which can affect gas flow and cut quality.

- Check Gas Supply and Pressure: Verify that oxygen, nitrogen, or air assist gas systems are stable and leak-free. Ensure filters are dry and free from oil or moisture that could contaminate the optics or cutting zone.

- Monitor the Chiller: Ensure the water chiller is filled with clean, distilled water and maintains a stable temperature (ideally 22℃–26℃). A consistent cooling environment protects the fiber laser source from overheating.

- Weekly Maintenance

- Lubricate Guide Rails and Rack System: Apply lubrication to the linear guides, rack and pinions, and rotation axis to prevent rust and ensure smooth operation. Lubrication schedules should match the manufacturer’s recommendation based on usage frequency.

- Drain the Air Compressor and Check Filters: Remove condensed water from the air tank and inspect the air dryer and filter units. Clean or replace filters if they appear dirty or saturated.

- Inspect Tube Feeding and Alignment Mechanisms: Check that the automatic loading system, pipe feeder, and alignment sensors are functioning correctly. Adjust rollers or rails if misalignment is detected.

- Monthly Maintenance

- Clean or Replace Focus Lens and Collimating Lens: Disassemble and inspect the cutting head optics for dust, discoloration, or micro-cracks. Clean if reusable; replace if damaged or affecting beam quality.

- Tighten Bolts and Check Belts: Check mechanical connections across the machine frame, gantry, and rotary chuck system. Retension belts and tighten loose bolts to ensure stable performance and prevent vibration.

- Calibrate the Auto-Focus and Centering Systems: Ensure that the cutting head’s autofocus and the tube centering system are calibrated properly for various tube diameters and shapes.

- Quarterly Maintenance

- Flush and Replace Chiller Water: Drain the chiller and refill with new distilled or deionized water to avoid mineral buildup, algae growth, and cooling inefficiency.

- Clean the Electrical Cabinet and Cooling Fans: Blow out dust from control panels, circuit boards, and cabinet fans. Excess dust can cause overheating or short circuits.

- Inspect Software Logs and System Alarms: Review the control software logs for repeated errors or warnings. Update firmware and software if available to improve system stability.

How Do Tube Laser Cutting Machines Reduce Material Waste?

- High-Precision Cutting: Tube laser cutting machines use a narrow, focused fiber laser beam that produces fine kerfs (cut widths), which means less material is removed during cutting. This allows components to be tightly nested and closely spaced, minimizing leftover scrap.

- Advanced Nesting Software: Modern machines come with intelligent CAD/CAM nesting systems that automatically arrange parts along the tube length to maximize usage. These programs calculate the most efficient layout, considering spacing, cutting path, and tube rotation, reducing unnecessary offcuts.

- Optimized Cut Sequencing: By programming the machine to cut holes, notches, and profiles in a smart sequence, tube laser cutting machines reduce repositioning and allow for multi-part cutting from a single tube segment, ensuring cleaner cuts and smoother transitions with minimal excess material.

- Reduced Setup and Transition Waste: Traditional tube processing methods—like sawing, drilling, punching, and milling—require repositioning and tool changes, which lead to material loss at each step. Tube laser cutting machines combine all these steps into a single-pass process, eliminating transition waste.

- Minimized End-of-Tube Remnants: Advanced machines can grip and process tubes from both ends or use short tail designs, minimizing the amount of material left unprocessed at the tube’s end (called tailing). This is especially valuable in high-volume or expensive material applications.

- Cutting Complex Geometries Without Additional Material: The ability to perform angled cuts, saddle joints, and interlocking profiles directly on the tube allows designers to eliminate connecting plates or extra materials, reducing overall consumption.

How Do Tube Laser Cutting Machines Reduce The Risk of Tube Deformation?

- Non-Contact Laser Cutting: Unlike mechanical tools, laser cutting is a non-contact process, meaning there’s no physical pressure applied to the tube’s surface. The laser beam melts the material with heat, not force, avoiding dents, warping, or crushing.

- Intelligent Clamping Systems: Tube laser machines use self-centering pneumatic or servo chucks that grip the tube evenly from all sides. These systems distribute clamping pressure uniformly, preventing localized stress that could distort the tube, especially with thin-walled profiles.

- Automated Support and Follow-Up Rollers: To support long tubes or pipes during rotation and feeding, the machine includes automated support rollers that follow the tube’s movement. This ensures the tube remains straight and level, avoiding sagging or bending under its weight.

- Dynamic Feed and Rotation Control: High-end machines are equipped with CNC-controlled feed rates and rotation speeds. These systems detect and adjust motion parameters in real-time, ensuring smooth transitions during cutting and minimizing vibration or torque that might deform the material.

- Low-Heat Input and High-Speed Cutting: Fiber lasers operate with efficient, focused heat, which is applied for only a short time. This limits thermal stress and heat-affected zones (HAZ) that can distort thin or lightweight tubes.

- Customized Settings for Thin-Walled Tubes: Software-controlled gas pressure, cutting speed, and power settings can be finely tuned for thin or sensitive materials, reducing internal stress and eliminating bulging or heat warping during piercing and cutting.