Product Introduction

Types of Sheet And Tube Laser Cutting Machines

-

FL-T Laser Cutting Machine

Rated 4.63 out of 5$44,200.00 – $237,250.00Price range: $44,200.00 through $237,250.00 Select options This product has multiple variants. The options may be chosen on the product page -

FE-T Laser Cutting Machine

Rated 4.75 out of 5$50,050.00 – $250,250.00Price range: $50,050.00 through $250,250.00 Select options This product has multiple variants. The options may be chosen on the product page -

FP-T Laser Cutting Machine

Rated 4.75 out of 5$56,550.00 – $263,250.00Price range: $56,550.00 through $263,250.00 Select options This product has multiple variants. The options may be chosen on the product page -

FH-A Laser Cutting Machine

Rated 4.63 out of 5$100,100.00 – $313,300.00Price range: $100,100.00 through $313,300.00 Select options This product has multiple variants. The options may be chosen on the product page

Application of Sheet And Tube Laser Cutting Machines

Why Choose Us

Cutting-Edge Technology

Every Faster Laser machine is built with the latest advancements, ensuring precise cuts, faster operation speeds, and the ability to handle complex designs effortlessly.

Superior Build Quality

We use only premium-grade materials and components, ensuring that every machine delivers consistent performance and maintains durability under heavy use.

Customized Solutions

Our team works closely with each customer to develop tailored laser cutting solutions that meet specific production needs and business objectives.

Comprehensive Support

Faster Laser provides thorough training, responsive technical support, and ongoing maintenance services to keep your machines running at peak efficiency.

Cost-Effective Investment

We offer high-quality laser cutting machines at competitive prices, ensuring you get maximum performance and long-term value from your investment.

Proven Industry Experience

With years of expertise and a strong global client base, Faster Laser has built a reputation for reliability, innovation, and customer satisfaction.

Sheet And Tube Laser Cutting Machines VS Other Cutting Machines

| Comparison Item | Sheet & Tube Laser Cutting Machine | Plasma Cutting Machine | Waterjet Cutting Machine | Flame Cutting Machine |

|---|---|---|---|---|

| Cutting Method | Fiber laser beam | Ionized gas arc | High-pressure water with abrasive | Oxy-fuel combustion |

| Material Types Supported | Metal sheets and tubes (SS, CS, Al, Brass) | Conductive metals | Almost all materials | Thick carbon steel only |

| Precision | Very high | Moderate | High | Low |

| Edge Finish | Clean, smooth, burr-free | Rough, may need finishing | Very smooth | Rough and oxidized |

| Heat Affected Zone (HAZ) | Very small | Medium | None | Large |

| Intricate Cuts | Excellent for detailed and complex designs | Limited by nozzle size | Excellent | Poor |

| Tube Cutting Capability | Built-in rotary system for various tube shapes | Not supported | Requires custom setup | Not supported |

| Speed | Fast | Fast | Slow to moderate | Slow |

| Operating Cost | Low | Moderate | High (abrasive + water cost) | Low |

| Maintenance | Low | Moderate | High (pump, nozzles, abrasive) | Low |

| Initial Equipment Cost | Moderate to high | Low to moderate | Very high | Low |

| Cutting Thickness Range | Thin to medium (sheet and tube) | Medium to thick metals | Thin to very thick | Medium to thick |

| Automation & CNC Integration | Excellent (CNC, nesting, auto load/unload) | Good | Limited | Minimal |

| Environmental Impact | Low (fume extraction, low waste) | Moderate (fumes, dross) | High (abrasive waste, water use) | High (gas emissions) |

| Industry Use Cases | Versatile – fabrication, auto, furniture, more | General metalwork | Aerospace, stone, specialty cutting | Heavy-duty steel structures |

Customer Testimonials

Related Resources

Laser Cutting VS Plasma Cutting: Which Is Better

Explore the differences between laser cutting and plasma cutting, including their working principles, applications, advantages, and limitations to help you choose the best method for your needs.

Frequently Asked Questions

What Is Sheet And Tube Laser Cutting?

- Sheet Metal Cutting: Sheet and tube laser machines efficiently cut flat sheets of carbon steel, stainless steel, aluminum, brass, copper, and galvanized steel. These machines use a gantry structure to move the cutting head over sheets of standard sizes (e.g., 3000×1500mm or 12000×2500mm), producing clean edges and intricate contours. They are ideal for industries such as:

- Sheet metal fabrication

- Electrical enclosures

- Elevator panels

- Machinery casings

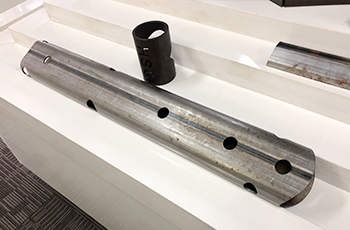

- Tube and Pipe Cutting: The integrated rotary device securely clamps and rotates various tube profiles, including round pipes, square tubes, rectangular tubes, and sometimes L-shaped or U-channel steel. This setup allows for advanced operations like:

- Notching

- Slotting

- Perforating

How Much Do Sheet And Tube Laser Cutting Machines Cost?

- Entry-Level Models ($45,000 – $80,000): These machines usually feature 1kW to 2kW laser power and basic rotary attachments for light-duty pipe cutting. They are suitable for small workshops, cutting thin sheets and small-diameter tubes (e.g., under 150mm). Most come with manual loading and limited automation.

- Mid-Range Models ($80,000 – $150,000): Machines in this range typically offer 2kW to 6kW fiber lasers, larger worktables (e.g., 1500×3000mm or 2000×4000mm), and automatic rotary chucks that handle round, square, and rectangular tubes. Ideal for metal fabrication businesses working with moderate volumes and a mix of sheet and tube materials.

- High-End Industrial Models ($150,000 – $320,000+): These machines come with 6kW to 12kW or even higher laser power, fully enclosed bodies, automated material loading/unloading systems, and advanced software for 3D tube profiling and bevel cutting. They can cut thick plates (up to 30mm or more) and large-diameter tubes (up to 300mm), suitable for industries like automotive, shipbuilding, and steel structure fabrication.

How Accurate Are Laser Cutting Machines For Sheet And Tube?

- Sheet Cutting Accuracy: When cutting flat sheet metal, fiber laser machines typically achieve a positioning accuracy of ±0.03 mm and a repeatability of ±0.02 mm. This allows for tight tolerances and clean cuts, even on intricate designs or thin metals. Laser cutting produces narrow kerfs and minimal thermal distortion, which is especially important for detailed parts or tight-fitting assemblies.

- Tube Cutting Accuracy: For pipes and profiles, the machine’s rotary axis or tube chuck system ensures consistent rotation and alignment. The cutting accuracy for tubes typically falls within ±0.05 mm, depending on tube diameter, wall thickness, and machine rigidity. These are all performed with high precision, reducing the need for secondary processing.

- Factors That Affect Accuracy

- Laser Power and Beam Quality: Higher-power lasers with stable beam output offer cleaner edges, especially on thicker materials.

- Servo Motor and Guide Rail Precision: High-end machines use servo motors and precision linear guides to maintain micron-level movement control.

- Tube Clamping System: A self-centering pneumatic chuck ensures the tube stays perfectly aligned during rotation and cutting.

- Software and Calibration: Professional nesting software and auto-calibration systems help ensure cutting paths are accurately executed every time.

What Shapes Can Sheet And Tube Laser Cutting Machines Cut?

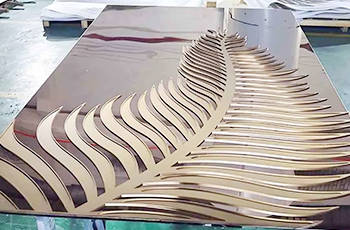

- Flat Sheet Shapes

- Straight Lines and Angles: Ideal for cutting square parts, frames, brackets, and structural panels.

- Curves and Circles: Used in decorative metalwork, covers, flanges, and custom-cut panels.

- Intricate Patterns: The fine laser beam allows for high-detail cutting of logos, ventilation grilles, ornamental designs, and gear profiles.

- Slots and Tabs: Essential for interlocking sheet metal structures, cabinets, and enclosure assembly.

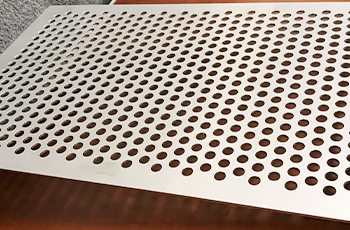

- Cutouts and Holes: Cleanly cut mounting holes, sensor ports, and access points in a variety of diameters and configurations.

- Tube and Pipe Shapes

- Straight Cuts Across Round/Square Tubes: Common for frame joints, railings, and support legs.

- Beveled or Angled Cuts: Ideal for weld prep and precision assembly in pipe-fitting or chassis fabrication.

- Perforations and Hole Arrays: For fluid or gas flow, weight reduction, or decorative purposes in metal tubing.

- Oblong or Custom Cutouts: Designed for tube-to-tube connections or insertion slots.

- Fish Mouth Cuts: Frequently used in round tube joints to create precise saddle cuts for structural welding.

- Notches and Slots: Enable snap-fit connections, drainage channels, or part identification features.

- 3D Profiles: On advanced models, complex tube contours and compound angles can be cut in one pass, especially useful for mechanical linkages and aerospace structures.

How Much Do Sheet And Tube Laser Cutting Machines Cost To Operate?

- Electricity: Fiber lasers and their auxiliary systems (like chillers and motors) consume varying amounts of power. A 3kW machine uses around 12- 15 kWh, while higher-power models (6kW-12kW) can use over 20 kWh. At an average rate of $0.10-$0.13/kWh, energy costs range from $1.50 to $5.00 per hour, depending on power level and usage.

- Assist Gas: Gas type significantly impacts cost. Oxygen (used for carbon steel) is affordable, costing about $2-$6/hour. Nitrogen (used for stainless steel and aluminum) is more expensive due to higher pressure needs, averaging $5-$20/hour. Compressed air, a cost-effective alternative, costs $1-$3/hour, including compressor electricity.

- Consumables and Maintenance: Daily wear parts like nozzles, lenses, and filters need regular replacement. Basic maintenance, including lubricants and cooling water management, adds about $1-$3/hour. Regular upkeep extends machine life and maintains cutting quality.

- Labor: Depending on the level of automation, one operator may manage one or multiple machines. Operator wages vary by region, but labor typically adds $15-$30/hour to the operating cost, especially in semi-automated setups.

- Software and Other Costs: Some nesting or control software requires annual licenses, costing $500-$1500/year, while system upgrades, training, and calibration contribute minor but recurring expenses.

What Spindle Power Options Are Available For CNC Routers?

- Enclosed Cutting Area: Many sheet and tube laser cutting machines come with a fully enclosed protective housing, often made of metal panels with laser-safe viewing windows. This enclosure blocks direct laser radiation, contains sparks and debris, and reduces noise, protecting both operators and nearby workers.

- Laser Safety Interlocks: All access doors and panels are equipped with interlock switches. If any door is opened while the laser is in operation, the interlock automatically stops the laser beam, preventing accidental exposure to harmful laser radiation.

- Emergency Stop Buttons: These machines are fitted with multiple emergency stop buttons, typically located on the main control panel, the machine body, and sometimes the handheld controller. These allow operators to immediately stop all machine activity in case of malfunction or emergency.

- Anti-Collision Sensor on Cutting Head: The cutting head includes collision detection systems that stop the laser and raise the head if unexpected contact with material or fixture occurs. This protects the cutting nozzle and lens from damage and minimizes the risk of fire or crashes.

- Automatic Height Control: Capacitive sensors on the cutting head automatically maintain a safe and consistent focus height between the nozzle and the material. This prevents the head from crashing into uneven surfaces and ensures safe operation across different material types.

- Fume Extraction System: A built-in or external fume extraction system removes smoke, vaporized metal particles, and potentially hazardous gases from the cutting area. This maintains air quality and prevents buildup that could lead to reduced visibility or fire risk.

- Rotary Chuck Safety Covers: In tube cutting mode, the rotating chuck that holds the pipe is often enclosed or guarded. This prevents operator injury from moving parts and keeps hands safely away from the tube rotation area.

- Gas Pressure and Flow Alarms: Machines are equipped with sensors to monitor and assist gas supply, including pressure and flow rates. Alarms alert the operator to leaks or supply issues, which could otherwise affect cut quality or safety.

- Cooling System Monitoring: The integrated industrial water chiller is protected with temperature and flow sensors. If the cooling system malfunctions, the laser automatically shuts off to prevent overheating or damage.

- Electrical Protection and Grounding: Proper grounding, surge protection, and circuit breakers are built into the system to prevent electrical accidents and protect the laser source and control system from unstable voltage.

- Software-Based Safety Controls: The control software limits user access based on authorization levels and restricts unsafe parameter combinations. Alarms, logs, and system diagnostics ensure the machine operates within safe boundaries.

How Long Is the Life of Sheet and Tube Laser Cutting Machines?

- Overall Machine Lifespan: With regular maintenance and moderate daily use, sheet and tube laser cutting machines typically have a service life of 8 to 12 years or more. Machines used in clean, climate-controlled environments and operated by trained personnel often last longer with fewer breakdowns.

- Fiber Laser Source: The laser generator is the core of the system and generally has a rated lifespan of 100,000 hours. High-quality laser sources from brands like IPG, Raycus, or MAX maintain stable power output for many years and require minimal upkeep. Proper cooling and power stability are key to maximizing this lifespan.

- Cutting Head and Optical Components: The lifespan of the cutting head assembly (including collimating and focusing lenses) typically ranges from 2 to 5 years, depending on usage frequency and material types. However, protective lenses and nozzles are consumables and may need replacement weekly or monthly, depending on workload.

- Rotary Tube Cutting Components: The rotating chuck, gear motors, and pipe supports in the tube cutting section can last 5–8 years or more with proper lubrication and alignment. Bearings, sensors, and belts may require periodic replacement due to rotational stress and dust exposure.

- Motion System (Guides, Rails, Motors): Precision linear guides, rack and pinions, and servo motors generally remain effective for 6–10 years with routine cleaning, lubrication, and calibration. Excessive vibration or debris can shorten this lifespan if not managed.

- Chiller and Auxiliary Systems: The industrial water chiller, air compressor, fume extractor, and gas regulators typically last 5–7 years. Regular filter changes, water quality management, and preventive servicing will help extend their life.

How To Maintain the Sheet And Tube Laser Cutting Machines?

- Daily Maintenance

- Clean the Cutting Table and Chuck Area: Remove slag, metal dust, and leftover material from the sheet cutting platform and the rotary chuck zone. Accumulated debris can affect cutting quality and cause fire risks.

- Inspect and Clean the Protective Lens and Nozzle: Dirt, fumes, or slag buildup can impair laser focus and gas flow. Clean the protective lens with specialized lens wipes and check for scratches. Inspect nozzles for warping or clogs.

- Check Gas Lines and Pressures: Ensure oxygen, nitrogen, and air lines are secure, dry, and free from leaks. Make sure gas pressures are within the recommended range before starting operations.

- Verify Chiller Water Levels and Temperature: Make sure the industrial water chiller is filled with clean, distilled, or deionized water. Maintain a water temperature between 22–26℃ for optimal laser performance.

- Weekly Maintenance

- Lubricate Linear Rails and Rack Gears: Apply lubricant to the guide rails, rack and pinion, and bearing systems to prevent wear and ensure smooth motion in both the sheet and tube cutting axes.

- Drain the Air Compressor and Check Filters: Release condensed water from the air tank and inspect oil separators and filters. Moisture or oil in compressed air can damage pneumatic valves and optics.

- Inspect the Rotary Chuck Mechanism: Clean dust and debris from the rotating chuck and confirm smooth tube rotation. Check for unusual vibration or slippage during operation.

- Clean the Dust Collector or Fume Extractor: Check filters for clogs and clean or replace them as needed to maintain effective ventilation and protect the optics from contamination.

- Monthly Maintenance

- Inspect the Focus Lens and Collimating Lens: Check internal optics for dirt, damage, or misalignment. Clean carefully or replace if necessary to maintain beam focus and cutting consistency.

- Calibrate the Automatic Height Follower: Ensure the cutting head’s height detection system responds correctly to changes in material surface and adjusts the focal distance without delay.

- Tighten Loose Fasteners: Vibration from tube rotation and sheet movement can loosen screws or bolts over time. Inspect mechanical joints, protective covers, and sensor mounts.

- Backup System Software and Parameters: Save cutting parameters, nesting programs, and machine settings to external storage or cloud backup in case of system reset or control failure.

- Quarterly or As-Needed Maintenance

- Replace Protective Lenses and Nozzles: These consumables wear with use and should be replaced regularly to avoid beam scatter or poor cutting edges.

- Flush and Replace Chiller Water: Prevent mineral buildup or algae growth by flushing out the water chiller and replacing it with fresh distilled water every 2–3 months.

- Check Servo Motors and Belts: Ensure the motors for both the gantry and rotary chuck are performing well. Inspect belts for cracks or tension issues and replace if worn.

- Update Software and Firmware: Stay up to date with the machine’s control software to improve system stability and ensure compatibility with newer file formats or nesting programs.