Product Introduction

Types of Fiber Laser Cutting Machines

-

FL-C Laser Cutting Machine

Rated 4.88 out of 5$22,360.00 – $94,900.00Price range: $22,360.00 through $94,900.00 Select options This product has multiple variants. The options may be chosen on the product page -

FL Laser Cutting Machine

Rated 4.88 out of 5$24,050.00 – $215,150.00Price range: $24,050.00 through $215,150.00 Select options This product has multiple variants. The options may be chosen on the product page -

FE Laser Cutting Machine

Rated 4.75 out of 5$29,900.00 – $228,150.00Price range: $29,900.00 through $228,150.00 Select options This product has multiple variants. The options may be chosen on the product page -

FB Laser Cutting Machine

Rated 4.75 out of 5$29,250.00 – $226,850.00Price range: $29,250.00 through $226,850.00 Select options This product has multiple variants. The options may be chosen on the product page -

FP Laser Cutting Machine

Rated 4.50 out of 5$35,750.00 – $240,500.00Price range: $35,750.00 through $240,500.00 Select options This product has multiple variants. The options may be chosen on the product page -

FH Laser Cutting Machine

Rated 4.75 out of 5$41,600.00 – $254,800.00Price range: $41,600.00 through $254,800.00 Select options This product has multiple variants. The options may be chosen on the product page -

FL-T Laser Cutting Machine

Rated 4.63 out of 5$44,200.00 – $237,250.00Price range: $44,200.00 through $237,250.00 Select options This product has multiple variants. The options may be chosen on the product page -

FE-T Laser Cutting Machine

Rated 4.75 out of 5$50,050.00 – $250,250.00Price range: $50,050.00 through $250,250.00 Select options This product has multiple variants. The options may be chosen on the product page

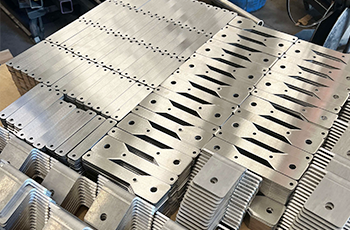

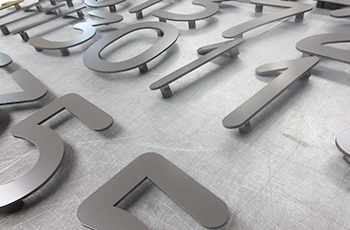

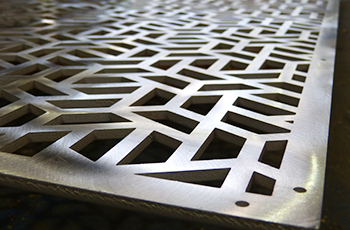

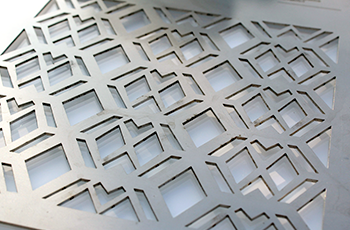

Application of Fiber Laser Cutting Machines

Why Choose Us

Cutting-Edge Technology

Every Faster Laser machine is built with the latest advancements, ensuring precise cuts, faster operation speeds, and the ability to handle complex designs effortlessly.

Superior Build Quality

We use only premium-grade materials and components, ensuring that every machine delivers consistent performance and maintains durability under heavy use.

Customized Solutions

Our team works closely with each customer to develop tailored laser cutting solutions that meet specific production needs and business objectives.

Comprehensive Support

Faster Laser provides thorough training, responsive technical support, and ongoing maintenance services to keep your machines running at peak efficiency.

Cost-Effective Investment

We offer high-quality laser cutting machines at competitive prices, ensuring you get maximum performance and long-term value from your investment.

Proven Industry Experience

With years of expertise and a strong global client base, Faster Laser has built a reputation for reliability, innovation, and customer satisfaction.

Fiber Laser Cutting Machines VS Other Cutting Machines

| Comparison Item | Fiber Laser Cutting Machine | Plasma Cutting Machine | Waterjet Cutting Machine | Flame Cutting Machine |

|---|---|---|---|---|

| Cutting Method | Fiber laser beam | Ionized gas arc | High-pressure water with/without abrasive | Oxy-fuel combustion |

| Best for Materials | Metals (steel, aluminum, brass, copper) | Conductive metals | Most materials, including stone and glass | Thick carbon steel |

| Cutting Precision | Very high | Moderate | High | Low |

| Cutting Speed | Fast | Fast | Slow to moderate | Slow |

| Edge Finish | Smooth and clean | Rougher, may need finishing | Very smooth | Rough and oxidized |

| Heat Affected Zone (HAZ) | Minimal | Medium | None | Large |

| Ability to Cut Reflective Metals | Excellent | Good | Good | Limited |

| Cutting Thickness Range | Thin to thick metals (varies by power) | Medium to thick metals | Wide, including very thick materials | Thick metals only |

| Operating Cost | Low | Moderate | High | Low |

| Maintenance Requirements | Low | Moderate | High | Low |

| Initial Equipment Cost | Moderate to high | Moderate | Very high | Low |

| Automation Capability | Excellent | Good | Limited | Poor |

| Environmental Impact | Low (no fumes with extraction) | Fumes and noise | Water waste, abrasive disposal | High emissions |

| Noise Level | Low | High | Moderate | High |

| Application Versatility | High (flat sheet, tube, complex shapes) | Good for general metal cutting | Broad material support | Limited to carbon steel |

Customer Testimonials

Related Resources

Laser Cutting VS Plasma Cutting: Which Is Better

Explore the differences between laser cutting and plasma cutting, including their working principles, applications, advantages, and limitations to help you choose the best method for your needs.

Frequently Asked Questions

What Power Options Are Available For Fiber Laser Cutting Machines?

- 1500W Fiber Laser: This entry-level power is ideal for cutting thin sheet metals. It can cut carbon steel up to 6mm, stainless steel up to 4mm, and aluminum up to 3mm. It offers a cost-effective solution for signage, kitchenware, and metal crafts, but may struggle with speed or quality on thicker materials.

- 2000W Fiber Laser: Slightly more powerful, this option improves cutting efficiency for mild steel up to 12mm and stainless steel up to 6mm. It’s popular in light manufacturing and metal processing shops. It provides a good balance between affordability and cutting capability for common industrial metals.

- 3000W Fiber Laser: A widely used mid-range power, 3000W systems handle carbon steel up to 16mm and stainless steel up to 8mm efficiently. It’s suitable for batch production, precision fabrication, and applications requiring versatility across material types and thicknesses.

- 4000W Fiber Laser: This power level allows high-speed cutting of carbon steel up to 20mm and stainless steel up to 12mm. It offers better edge quality and is ideal for industrial fabrication, equipment housings, and metal enclosures.

- 6000W Fiber Laser: A higher-performance machine for thicker sheets, cutting carbon steel up to 25mm and stainless steel up to 16mm. Its faster cutting speed improves production throughput and is commonly used in automotive and heavy machinery sectors.

- 12000W Fiber Laser: A high-power option for cutting thick carbon steel up to 40mm and stainless steel up to 30mm. It is suitable for construction, shipbuilding, and energy equipment. It also performs ultra-fast cuts on thin sheets, improving productivity in mass production.

- 20000W Fiber Laser: Designed for extremely demanding tasks, this power level can cut carbon steel up to 50mm and stainless steel up to 40mm. It enables rapid, clean cuts and supports large-scale manufacturing in industries like aerospace, structural steel, and pressure vessels.

- 30000W Fiber Laser: At this level, fiber lasers can cut carbon steel up to 80mm and stainless steel up to 50mm. This power is often reserved for manufacturers handling thick plate processing, large-format jobs, or continuous high-volume orders.

- 40000W Fiber Laser: The highest standard power level, capable of cutting carbon steel up to 100mm and stainless steel up to 60mm. It offers unparalleled cutting depth and speed, replacing some traditional cutting methods for ultra-thick and high-strength materials in shipbuilding, steel fabrication, and military-grade production.

What Auxiliary Equipment Is Required For Fiber Laser Cutting Machines?

- Industrial Water Chiller: Maintains optimal operating temperatures for the laser source and cutting head. A dual-circuit system cools both independently. The chiller must use distilled or deionized water and should be cleaned and refilled regularly to avoid scale buildup and overheating.

- Air Compressor and Air Dryer: Supplies compressed air as an assist gas for cutting certain materials like aluminum or stainless steel. An air dryer ensures the compressed air is moisture-free, which protects optics and pneumatic components from corrosion or condensation.

- Gas Supply System: Oxygen, nitrogen, and sometimes compressed air are used to aid in the cutting process. Oxygen enhances speed for carbon steel, nitrogen ensures clean cuts on stainless steel, and compressed air offers a low-cost option for less demanding jobs. Gas pressure regulators, valves, and pipelines are also necessary.

- Fume Extractor or Dust Collector: Removes smoke, metal particles, and potentially toxic gases generated during cutting. A high-efficiency fume extractor with HEPA filters ensures a clean working environment and protects machine optics from contamination.

- Slag Collection System: Collects debris and molten material from beneath the cutting area. Regular cleaning helps prevent fire risks and improves airflow under the cutting zone.

- Red Dot Pointer or Camera System (Optional): Assists in positioning the material and previewing the cutting path before actual cutting. Especially useful for alignment in manual setups or prototyping.

- Nesting Software: Optimizes cutting layout and material utilization. Software like CypNest or Lantek helps reduce waste and streamline production planning.

What Gases Are Required For Fiber Laser Cutting?

- Oxygen (O2)

- Purpose: Reactive cutting gas that accelerates the cutting process through exothermic reactions.

- Materials: Primarily used for carbon steel and other ferrous metals.

- Effect: Oxygen increases cutting speed by reacting with the metal to generate additional heat, but the edges will oxidize slightly (blacken) and may require subsequent treatment.

- Pressure Range: Typically 0.3 – 1.0 MPa (depending on material thickness).

- Note: Lower gas cost but lower edge quality compared to nitrogen.

- Nitrogen (N2)

- Purpose: Inert shielding gas that protects the cutting edge from oxidation.

- Materials: Best for stainless steel, aluminum, brass, and galvanized sheet.

- Effect: Nitrogen cuts produce clean, bright, oxidation-free edges, ideal for aesthetic or weldable parts, but require higher pressures to blow the molten material out of the cut.

- Pressure Range: 1.0 – 2.5 MPa or higher, depending on material thickness.

- Note: More expensive than oxygen, but eliminates the need for edge finishing.

- Compressed Air

- Purpose: Budget-friendly assist gas for cutting non-critical parts.

- Materials: Suitable for mild steel, aluminum, and stainless steel (thin sheets).

- Effect: Compressed air contains about 78% nitrogen and about 21% oxygen, providing a partial mix of the two gases, but the cutting speed will be slower, and the edge finish may not be as clean as with pure nitrogen.

- Pressure Range: 0.8 – 1.6 MPa.

- Note: Requires a high-quality air compressor and air dryer to remove moisture and oil.

- Argon (Ar) (Rarely used)

- Purpose: Inert gas is used for specialized applications like reactive metal cutting.

- Materials: Sometimes used for titanium or magnesium alloys.

- Effect: Argon provides the most stable chemical environment, preventing oxidation, but is costly, has low thermal conductivity, and reduces cutting efficiency.

- Pressure Range: Similar to nitrogen.

- Note: Mainly used in aerospace or medical industries where purity is critical.

What Are The Working Environment Requirements For Fiber Laser Cutting Machines?

- Temperature and Humidity Control: Fiber lasers operate best in stable conditions. The ideal ambient temperature ranges from 15℃ to 30℃ (59℉ to 86℉). Temperatures below or above this range can reduce cutting performance or damage internal electronics. Humidity should be kept between 40% and 70%, and condensation must be avoided, as moisture can corrode optics and electrical systems.

- Ventilation and Fume Extraction: Laser cutting generates metal dust, fumes, and sometimes toxic gases, especially when cutting galvanized steel, aluminum, or coated metals. The machine must be installed in a well-ventilated area with an effective fume extractor or dust collector to remove particles and gases, ensuring clean air and preventing contamination of optical elements.

- Stable Power Supply: A stable, uninterrupted power source is crucial. Most fiber laser machines run on three-phase 380V or 220V power, depending on configuration. Power fluctuations can damage sensitive components or interrupt cutting jobs. Voltage regulators or UPS systems are recommended in areas prone to electrical instability.

- Solid, Vibration-Free Foundation: The machine should be installed on a flat, level surface that can support its weight and isolate it from vibrations. Uneven or unstable foundations may lead to cutting inaccuracies, mechanical wear, or optical misalignment over time.

- Clean and Dry Environment: Fiber lasers require a dust-free and oil-free workspace. Accumulated dust or oil mist can settle on the laser head, lenses, or motors, leading to errors, overheating, or beam quality issues. Regular cleaning of the machine’s surroundings and surfaces is essential.

- Clearance Space: There should be at least 1-5 meters of space around the machine for safe operation, material handling, and maintenance access. This spacing also helps with air circulation and heat dissipation.

- Lighting and Safety Measures: The workspace should be well-lit to ensure visibility during material setup and monitoring. Safety measures such as laser enclosures, emergency stop buttons, warning signs, and personal protective equipment (PPE) are vital to protect operators from laser exposure and mechanical hazards.

What Materials Can Fiber Laser Cutting Machines Cut?

- Carbon Steel: Fiber lasers cut carbon steel with excellent edge quality and high cutting speeds. Low- and medium-carbon steels are commonly used in structural fabrication, automotive parts, and machinery. With increasing laser power (e.g., 3kW-30kW), fiber lasers can cut thicknesses ranging from 0.5mm to 80mm.

- Stainless Steel: Stainless steel is ideal for fiber lasers, which can produce clean, burr-free cuts without oxidation when nitrogen is used as an assist gas. It’s widely used in food processing, medical devices, and architectural applications. Fiber lasers can cut stainless steel up to 50mm, depending on the power level.

- Aluminum and Aluminum Alloys: Fiber lasers are highly effective for cutting aluminum, including 5052 and 6061 grades. The reflective nature of aluminum is well handled by fiber wavelengths. With appropriate power and gas settings, cutting thicknesses up to 30mm are achievable.

- Brass: Brass is a reflective and thermally conductive material, but fiber lasers can cut it with precision using nitrogen to avoid oxidation. Common in decorative items, plumbing components, and electrical terminals, brass can be cut up to 18mm thick with high-power lasers.

- Copper: Copper’s high reflectivity and thermal conductivity make it difficult for CO2 lasers, but fiber lasers perform well, especially with high-power models. Fiber lasers can cut pure copper up to 12mm, making them suitable for electrical and electronics manufacturing.

- Titanium: Fiber lasers are suitable for cutting titanium and its alloys, commonly used in aerospace, medical implants, and high-performance engineering. Cuts are precise and clean, typically assisted by inert gases like nitrogen or argon to prevent oxidation.

- Galvanized Steel: Galvanized sheet metal can be cut with fiber lasers, though care must be taken to control fumes and zinc buildup. It’s commonly used in ductwork, enclosures, and structural parts.

- Nickel Alloys (e.g., Inconel, Hastelloy): Fiber lasers can cut high-strength, heat-resistant nickel-based alloys used in aerospace, power generation, and chemical processing. Clean edges and tight tolerances are achievable.

- Gold, Silver, and Precious Metals: Thin sheets of precious metals like gold and silver can be cut with fiber lasers in jewelry manufacturing or precision electronics. Fiber lasers offer excellent detail for intricate designs without causing material discoloration or warping.

How To Maintain Fiber Laser Cutting Machines?

- External Inspection and Cleaning

- Machine Surface and Enclosure: Clean dust, oil, and debris from the exterior and enclosure regularly to keep the machine safe and professional. This also prevents contaminants from entering the system.

- Worktable: Remove metal slag, burrs, and residue from the cutting bed daily. Excess buildup can affect material flatness and airflow beneath the sheet, impacting cut quality.

- Optical Components Inspection

- Laser Cutting Head Lens: Check and clean the protective lens regularly using lens paper and isopropyl alcohol. Dust, smoke, or splatter can damage the lens and degrade beam quality.

- Nozzle Condition: Inspect the nozzle for deformation, dirt, or blockages. A damaged nozzle can disrupt gas flow, resulting in poor cuts or inconsistent piercing. Replace if worn.

- Mechanical Components Maintenance

- Linear Guides and Rack Gears: Wipe clean and apply lubricant as recommended by the manufacturer. Accumulated debris or a lack of oil can increase wear and reduce accuracy.

- Z-Axis Movement and Bearings: Check for smooth motion. Apply grease or oil to bearings and moving parts based on the lubrication schedule.

- Fasteners and Belts: Tighten loose bolts and check belt tension. A slack or misaligned belt affects cutting precision and acceleration response.

- Electrical System Checks

- Cables and Connectors: Visually inspect power and signal cables for wear, exposed wires, or loose plugs. Electrical instability can lead to malfunctions or safety hazards.

- Grounding System: Ensure grounding is secure to prevent electrical interference or laser source damage.

- Control Cabinet: Clean dust filters and verify that ventilation fans are working properly. Overheating can cause system failure or shorten component lifespan.

- Cooling System Maintenance

- Water Quality: Use only distilled or deionized water. Replace every 1-2 months.

- Water Level: Check and refill as needed.

- Temperature Setting: Maintain water temperature between 22℃ and 26℃.

- Chiller Filter and Fan: Clean regularly to ensure cooling efficiency.

- Gas Supply System Maintenance

- Assist Gas Lines (Oxygen, Nitrogen, Air): Check for leaks, pressure irregularities, and moisture. Ensure filters and regulators are clean and functional.

- Air Compressor and Dryer (if used): Drain moisture from air tanks and maintain air purity. Moisture in the system can damage valves and optics.

- Laser Source Maintenance

- Fiber Laser Generator: Typically maintenance-free, but it should be kept cool and clean. Monitor power output levels; a gradual drop may indicate aging or a fault.

- Operational Logs: Record cutting hours, maintenance actions, and fault history. This helps identify trends and plan preventive servicing.

- Software and System Checks

- Firmware Updates: Ensure the control software is up to date. New versions may fix bugs or improve performance.

- File Management: Back up cutting parameters and user files regularly to avoid data loss.

What Is The Service Life Of Fiber Laser Cutting Machines?

- Fiber Laser Source (Laser Generator)

- Service Life: Generally rated for 100,000 hours of operation.

- Factors: High-quality brands like IPG, Raycus, or MAX tend to last longer and maintain stable output over time.

- Maintenance: Since fiber lasers are solid-state and air-sealed, they require minimal maintenance and have no consumable gas like CO2

- Cutting Head and Optics

- Service Life: Depends on usage and care; typically 2-3 years for the lens assembly, but consumables like protective lenses and nozzles require frequent replacement.

- Tip: Regular cleaning and use of clean assist gas prolong their life.

- CNC Motion System (Rails, Motors, and Bearings)

- Service Life: 5-8 years under normal wear.

- Factors: Precision and wear resistance of linear guides, rack and pinion systems, and servo motors affect longevity.

- Maintenance: Proper lubrication and dust protection are essential to prevent mechanical degradation.

- Control System and Electronics

- Service Life: 8-10 years, aligned with the machine itself.

- Note: Software and hardware updates may be needed after 5+ years to maintain compatibility and function.

- Chiller and Auxiliary Equipment

- Service Life: Typically 5-7 years, depending on operating conditions and water quality.

- Tip: Regular filter cleaning, water changes, and proper ambient placement can extend life.

- Machine Frame and Enclosure

- Service Life: Over 10 years, as long as there’s no structural damage or corrosion.

- Consideration: A stable frame ensures long-term accuracy and cutting consistency.

- Usage Intensity and Environmental Impact

- Machines running 24/7 in high-volume production may experience faster wear on optics, motion systems, and consumables.

- Dusty, humid, or unstable environments can shorten service life unless mitigated with proper ventilation, temperature control, and protective measures.

How To Handle Fumes During Fiber Laser Cutting?

- Fume Extraction Systems: Fiber laser cutting machines must be paired with a dedicated fume extraction system that draws fumes directly from the cutting area. These systems typically include industrial fans and ducting that pull contaminated air into a multi-stage filtration unit. They prevent smoke buildup, protect the optics and sensors, and reduce airborne particles in the workshop.

- Filtration Units: A high-efficiency filter unit typically includes pre-filters, HEPA filters, and activated carbon filters:

- Pre-filters trap larger metal dust particles and sparks.

- HEPA filters capture fine particulates and ultrafine metal fumes.

- Activated carbon filters absorb toxic gases and odors, such as those released when cutting galvanized steel or aluminum.

- Enclosed Cutting Environment: Many fiber laser cutting machines come with a fully enclosed cutting chamber, which helps isolate smoke and fumes within the machine. This makes extraction more efficient and protects operators from direct exposure. Some machines include negative pressure zones that actively pull smoke away from the cutting area.

- Ducting and Exhaust Ventilation: Fume-laden air should be vented outside the building or into a centralized air purification system. Use high-temperature-resistant ducting with minimal bends to maintain airflow efficiency. Ensure exhaust outlets are positioned away from air intakes or populated areas.

- Maintenance of Extraction Systems: Regularly clean or replace filters, inspect ducting for blockages, and check fan operation to ensure consistent airflow. A poorly maintained system reduces fume extraction efficiency and can become a safety hazard over time.

- Compressed Air and Assist Gas Purity: Moisture or oil in compressed air can cause additional vapor emissions and contaminate optics. Use a dry, oil-free air compressor and air dryer to ensure clean air delivery during cutting operations.

- Personal Protection and Monitoring: While enclosed systems and fume extractors provide the main protection, in high-exposure areas, operators may still use PPE like N95 masks, air quality monitors, or ventilation alarms to ensure workplace safety.