Product Introduction

Types of CO2 Laser Cutting Machines

-

FC Laser Cutting Machine

Rated 4.75 out of 5$3,055.00 – $12,350.00Price range: $3,055.00 through $12,350.00 Select options This product has multiple variants. The options may be chosen on the product page -

FC-C Laser Cutting Machine

Rated 4.50 out of 5$4,615.00 – $15,990.00Price range: $4,615.00 through $15,990.00 Select options This product has multiple variants. The options may be chosen on the product page -

FC-E Laser Cutting Machine

Rated 4.50 out of 5$3,575.00 – $12,870.00Price range: $3,575.00 through $12,870.00 Select options This product has multiple variants. The options may be chosen on the product page -

FC-K Laser Cutting Machine

Rated 5.00 out of 5$5,525.00 – $13,650.00Price range: $5,525.00 through $13,650.00 Select options This product has multiple variants. The options may be chosen on the product page -

FC-D Laser Cutting Machine

Rated 4.38 out of 5$3,705.00 – $13,000.00Price range: $3,705.00 through $13,000.00 Select options This product has multiple variants. The options may be chosen on the product page -

FC-A Laser Cutting Machine

Rated 5.00 out of 5$6,955.00 – $14,950.00Price range: $6,955.00 through $14,950.00 Select options This product has multiple variants. The options may be chosen on the product page -

FC-KD Laser Cutting Machine

Rated 4.63 out of 5$6,175.00 – $14,300.00Price range: $6,175.00 through $14,300.00 Select options This product has multiple variants. The options may be chosen on the product page -

FC-KA Laser Cutting Machine

Rated 4.63 out of 5$6,825.00 – $15,470.00Price range: $6,825.00 through $15,470.00 Select options This product has multiple variants. The options may be chosen on the product page

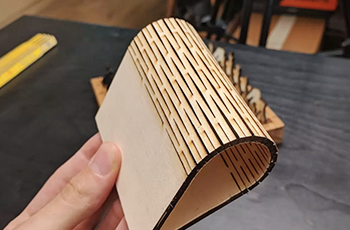

Application of CO2 Laser Cutting Machines

Why Choose Us

Cutting-Edge Technology

Every Faster Laser machine is built with the latest advancements, ensuring precise cuts, faster operation speeds, and the ability to handle complex designs effortlessly.

Superior Build Quality

We use only premium-grade materials and components, ensuring that every machine delivers consistent performance and maintains durability under heavy use.

Customized Solutions

Our team works closely with each customer to develop tailored laser cutting solutions that meet specific production needs and business objectives.

Comprehensive Support

Faster Laser provides thorough training, responsive technical support, and ongoing maintenance services to keep your machines running at peak efficiency.

Cost-Effective Investment

We offer high-quality laser cutting machines at competitive prices, ensuring you get maximum performance and long-term value from your investment.

Proven Industry Experience

With years of expertise and a strong global client base, Faster Laser has built a reputation for reliability, innovation, and customer satisfaction.

CO2 Laser Cutting Machines VS Other Cutting Machines

| Comparison Item | CO2 Laser Cutting Machine | CNC Router | Mechanical Saws | Knife Cutting Machine |

|---|---|---|---|---|

| Cutting Method | Laser beam | Rotary cutting tool | Spinning blade | Oscillating or drag knife |

| Suitable Materials | Non-metal: wood, acrylic, plastic, leather | Wood, plastic, soft metals | Wood, metal, plastic | Fabric, foam, leather, cardboard |

| Cutting Precision | Very high | Moderate | Low to moderate | High |

| Edge Finish | Smooth and clean | May require sanding | Rough, often needs post-processing | Clean, may vary with material |

| Cutting Speed | Fast | Moderate | Fast | Moderate |

| Maintenance | Low | Moderate | High (blade wear) | Moderate |

| Operating Noise | Low | Loud | Very loud | Low |

| Material Waste | Minimal | Moderate | High | Low |

| Tool Wear | None | High (bits wear out) | High (blades dull) | Blades may dull |

| Design Complexity Handling | Excellent (fine details, curves) | Limited by tool path | Poor for intricate designs | Good for simple patterns |

| Setup Time | Short | Moderate | Short | Short |

| Automation Integration | Easy | Moderate | Limited | Moderate |

| Cutting Thickness Range | Thin to moderate (depends on power) | Wide (depends on bit and spindle power) | Wide | Thin materials only |

| Initial Equipment Cost | Moderate | Low to moderate | Low | Low to moderate |

| Operating Cost | Low | Moderate | Low | Low |

Customer Testimonials

Related Resources

Laser Cutting VS Waterjet Cutting

This article compares laser cutting and waterjet cutting, covering processes, materials, costs, precision, and applications to help manufacturers select the best method.

Laser Cutting VS Plasma Cutting

This article explores a detailed comparison of laser cutting and plasma cutting, including how each process works, material ranges, cut quality, speed, costs, safety, and key selection factors.

Frequently Asked Questions

What Is The Price Of CO2 Laser Cutting Machines?

- Entry-Level Models ($3,100-$6,000): These machines are usually desktop or benchtop units with lower wattage (40W-80W), ideal for small businesses, hobbyists, or light-duty use. They can cut materials like wood, acrylic, leather, and certain plastics, but may struggle with thicker or denser materials.

- Mid-Range Machines ($6,000-$10,000): These offer more power (80W-150W), larger working areas, and better components, including improved cooling systems and higher-precision optics. They’re suitable for small to medium-sized workshops with moderate production demands.

- Industrial-Grade CO2 Lasers ($10,000-$16,000): These are built for continuous operation and can cut thicker materials with greater speed and accuracy. They often include advanced features like autofocus, motorized beds, and integrated fume extraction. They’re designed for heavy use in commercial settings.

- Optional Costs: Some manufacturers offer upgrades (e.g., rotary attachments, software packages, or custom enclosures) that can increase the price. Shipping, taxes, and installation fees may also apply.

What Are The Disadvantages Of CO2 Laser Cutting Machines?

- Limited Material Compatibility: CO2 laser cutting machines excel at cutting non-metal materials like wood, acrylic, and plastics, but they struggle with reflective metals such as aluminum or copper. Cutting metals often requires special coatings or higher power, making fiber lasers a better choice for those applications.

- High Maintenance Requirements: CO2 laser cutting machines use glass tubes, mirrors, and lenses that degrade over time and require regular cleaning, alignment, or replacement. Cooling systems also need monitoring and maintenance to avoid overheating.

- Size and Footprint: These machines can be large and heavy, especially industrial models. They often need dedicated floor space, ventilation, and sometimes structural modifications to the workspace.

- Lower Efficiency Compared to Fiber Lasers: CO2 laser cutting machines typically have lower electrical-to-optical conversion efficiency (10-15%) compared to fiber lasers (30-50%), which leads to higher energy consumption and operating costs for similar tasks.

- Slower Cutting Speeds for Metals: When cutting thin sheet metal, CO2 laser cutting machines are generally slower and less efficient than fiber lasers. This makes them less ideal for high-speed production environments focused on metal processing.

- Sensitive Optics and Beam Alignment: Optical components are delicate and prone to misalignment or contamination, which can degrade cut quality and require downtime for adjustments or replacements.

- Cooling System Dependence: CO2 laser cutting machines rely on water or air cooling systems to function safely. Any failure in the cooling system can cause significant damage to the laser tube or optics.

- Higher Consumable Costs: Over time, the cost of replacing laser tubes, mirrors, lenses, and coolant adds up, especially for machines in heavy use.

What Materials Can CO2 Laser Cutting Machines Cut?

- Wood and Wood-Based Products: CO2 lasers cut plywood, MDF, hardwood, softwood, and veneer with clean edges. However, some woods may char or ignite, so proper settings and ventilation are key.

- Acrylic and Plastics: Acrylic (PMMA) cuts cleanly with a polished edge finish, making it one of the most popular laser materials. Other plastics like ABS, Delrin (acetal), and polyethylene can also be cut, but each varies in fume production and cut quality. PVC should never be cut due to toxic chlorine gas.

- Paper and Cardboard: Thin, flammable materials like paper, cardboard, and chipboard are easily cut with CO2 lasers. These materials ignite quickly, so constant supervision and air assist are important.

- Leather and Fabrics: Natural leather and many textiles (like cotton, polyester, felt, or denim) can be cut and engraved. Synthetic leathers and vinyls should be avoided unless verified safe, as they may release harmful fumes.

- Rubber: Certain laser-safe rubbers can be cut for gaskets or stamps. However, many rubbers (especially those with chlorine content) are unsafe and emit noxious gases.

- Foam: EVA foam, polyethylene foam, and similar materials cut well with CO2 lasers, often used for inserts or packaging. Fire risk is high without supervision and proper air extraction.

- Glass and Ceramics (Engraving Only): While CO2 lasers can’t cut through glass or ceramics, they can engrave the surface for decorative or functional purposes.

- Thin Non-Ferrous Metals (with limitations): CO2 lasers can sometimes cut thin aluminum, brass, or copper if coated or painted, but reflective surfaces reduce efficiency and can damage the laser. Fiber lasers are better for metals.

Do I Need Glasses When Cutting With CO2 Lasers?

- Laser Safety Glasses Are Strongly Recommended: While the CO2 laser beam is not visible, its infrared energy can still harm your eyes, especially through reflections or scattered light. Proper laser safety glasses rated for 10.6 µm wavelength significantly reduce this risk.

- Protection Depends on the Machine Setup: Enclosed or industrial CO2 laser cutting machines with built-in safety enclosures may not require additional glasses if the system is fully sealed and interlocked. However, open-bed or desktop lasers without protective housing do require glasses.

- Choose the Right Optical Density (OD): Not all safety glasses work for CO2 lasers. You need glasses that are specifically rated for OD 5+ at 10.6 µm or higher. Using the wrong type (e.g., visible-light glasses or fiber laser-rated glasses) won’t protect your eyes.

- Reflections Are Still Dangerous: Even diffuse reflections off materials like acrylic or metal can be hazardous with a powerful CO2 laser. Always wear protection if there’s any chance of beam exposure.

- Workplace Regulations May Apply: In labs, educational, or professional settings, eye protection might be legally required depending on your local health and safety rules.

What Is The Service Life Of CO2 Laser Cutting Machines?

- Laser Tube Lifespan: The CO2 laser tube is the heart of the machine and typically lasts 1,500 to 10,000 hours, depending on the type (glass vs. metal RF tube). Glass tubes are cheaper but usually last 1,500-3,000 hours, while metal tubes can exceed 8,000-10,000 hours with consistent performance.

- Optics and Mirrors: Mirrors and lenses require cleaning and occasional replacement. With proper care, they can last 6 months to 2 years. Dirty or misaligned optics degrade performance and shorten laser tube life.

- Cooling System: Water-cooled CO2 lasers rely on a stable cooling system. Regular coolant changes and pump maintenance ensure the system runs efficiently and prevent tube damage. Neglect can severely reduce machine life.

- Mechanical Components: Belts, rails, bearings, and stepper motors wear over time. With routine lubrication and cleaning, these parts can last 5-10 years or longer. Heavy use or poor maintenance shortens their lifespan.

- Power Supply and Electronics: The power supply usually lasts 3-7 years, but voltage fluctuations, overheating, or dust can cause premature failure. Keeping the machine in a clean, dry environment extends the life of electronic components.

- Overall Machine Lifespan: With routine maintenance and part replacements, CO2 laser-cutting machines can operate effectively for 8-15 years. Industrial-grade machines tend to last longer than entry-level desktop units.

Does CO2 Laser Cutting Require Gas?

- Air Assist (Most Common): A steady stream of compressed air is blown through the nozzle during cutting to remove debris, cool the material, and reduce flare-ups. This is essential for clean edges, especially when cutting wood, acrylic, or paper. Air assist also protects the lens from smoke and particles.

- Oxygen (For Certain Materials): Though rarely used with CO2 lasers, oxygen can be used to assist cutting of some thin metals or specific foams. It supports combustion and speeds up cutting, but it increases the risk of fire and requires precise control.

- Nitrogen (For High-Quality Edges): Nitrogen is occasionally used when a clean, oxidation-free edge is needed, especially in applications where discoloration must be avoided. It’s more common with fiber lasers, but can be used in hybrid setups.

- CO2 Laser Tube Gas (Internal): Inside the laser tube itself, a sealed mixture of carbon dioxide, nitrogen, and helium is excited to produce the laser beam. This internal gas is part of the tube’s construction and not something the user typically supplies or replaces.

- Compressor or Gas Source Required: Most machines require either a built-in or external air compressor. For setups using oxygen or nitrogen, cylinders or gas lines are necessary.

Does CO2 Laser Cutting Produce Harmful Gases?

- Wood and Wood-Based Products

- Cutting plywood, MDF, or particleboard can release formaldehyde, acrolein, and carbon monoxide, especially from adhesives and resins. These are toxic and may cause eye, respiratory, or neurological irritation.

- Acrylic and Plastics

- Acrylic (PMMA) releases methyl methacrylate, which is flammable and irritating.

- Plastics like ABS and polycarbonate produce hydrogen cyanide, styrene, and phenol, which are all hazardous.

- PVC should never be cut—it emits hydrogen chloride gas, which forms hydrochloric acid when inhaled, damaging lungs and corroding equipment.

- Paper and Cardboard

- Cutting paper and cardboard typically produces carbon monoxide and fine particulates, which can accumulate and pose health risks if ventilation is poor.

- Leather and Fabrics

- Natural leather emits ammonia, aldehydes, and organic compounds when lasered.

- Synthetic leathers or fabrics like polyester and nylon may emit cyanides, isocyanates, or phosgene, depending on their chemical makeup.

How To Maintain CO2 Laser Cutting Machines?

- Optical System Maintenance

- Clean the Laser Lens and Mirrors: Use lens-cleaning paper and isopropyl alcohol to gently clean the focusing lens and mirrors. Do this regularly, especially if cutting materials that generate smoke or dust.

- Check for Scratches or Cracks: Damaged optics should be replaced immediately to avoid beam distortion or energy loss.

- Laser Tube Inspection

- Monitor Power Output: If you notice a drop in cutting performance, the laser tube may be aging or losing efficiency.

- Cooling Water Quality: Use distilled or deionized water to prevent mineral buildup and replace it every 1-2 weeks.

- Check Water Temperature: Keep it between 18℃-22℃ to prevent thermal stress on the CO2 tube.

- Cooling System Care

- Clean the Water Chiller: Regularly remove dust and check water flow. A dirty or clogged chiller can overheat the laser tube.

- Inspect Pipes for Leaks or Kinks: Ensure uninterrupted water flow to maintain laser tube life.

- Air Assist and Exhaust System

- Clean Air Filters and Fans: Blocked filters reduce airflow, leading to poor smoke removal and potential lens contamination.

- Check Air Pump or Compressor: Ensure consistent air pressure to prevent flare-ups and maintain clean cuts.

- Clear Exhaust Ducts: Remove residue or debris to maintain efficient fume extraction.

- Motion System Maintenance

- Lubricate Linear Rails and Bearings: Use the manufacturer-recommended lubricant to keep moving parts smooth and rust-free.

- Tighten Belts and Check Tension: Loose belts can lead to inaccurate cuts. Replace any that show signs of wear or fraying.

- Check Stepper Motors or Servos: Listen for unusual noises and ensure proper alignment and torque.

- Electrical and Control Components

- Inspect Wiring and Connections: Look for loose terminals, exposed wires, or signs of overheating.

- Update Software and Firmware: Ensure your control system is running the latest version for optimal performance and compatibility.

- Worktable and Surface Cleaning

- Remove Residual Debris: Ash, resin, and melted material buildup on the honeycomb or blade table can affect airflow and cut quality.

- Keep the Red Dot Pointer Clean: If applicable, keep it aligned and clean to assist with accurate positioning.

- General Preventive Measures

- Follow a Maintenance Schedule: Set daily, weekly, and monthly tasks to track cleaning and inspection routines.

- Keep an Operation Log: Note down errors, maintenance actions, and performance issues for better troubleshooting.

- Train Operators: Ensure staff know how to handle the machine, perform basic cleaning, and recognize warning signs.