Product Introduction

Types of Laser Cutting Machines

-

FL-C Laser Cutting Machine

Rated 4.88 out of 5$22,360.00 – $94,900.00Price range: $22,360.00 through $94,900.00 Select options This product has multiple variants. The options may be chosen on the product page -

FL Laser Cutting Machine

Rated 4.88 out of 5$24,050.00 – $215,150.00Price range: $24,050.00 through $215,150.00 Select options This product has multiple variants. The options may be chosen on the product page -

FE Laser Cutting Machine

Rated 4.75 out of 5$29,900.00 – $228,150.00Price range: $29,900.00 through $228,150.00 Select options This product has multiple variants. The options may be chosen on the product page -

FB Laser Cutting Machine

Rated 4.75 out of 5$29,250.00 – $226,850.00Price range: $29,250.00 through $226,850.00 Select options This product has multiple variants. The options may be chosen on the product page -

FP Laser Cutting Machine

Rated 4.50 out of 5$35,750.00 – $240,500.00Price range: $35,750.00 through $240,500.00 Select options This product has multiple variants. The options may be chosen on the product page -

FH Laser Cutting Machine

Rated 4.75 out of 5$41,600.00 – $254,800.00Price range: $41,600.00 through $254,800.00 Select options This product has multiple variants. The options may be chosen on the product page -

FL-T Laser Cutting Machine

Rated 4.63 out of 5$44,200.00 – $237,250.00Price range: $44,200.00 through $237,250.00 Select options This product has multiple variants. The options may be chosen on the product page -

FE-T Laser Cutting Machine

Rated 4.75 out of 5$50,050.00 – $250,250.00Price range: $50,050.00 through $250,250.00 Select options This product has multiple variants. The options may be chosen on the product page

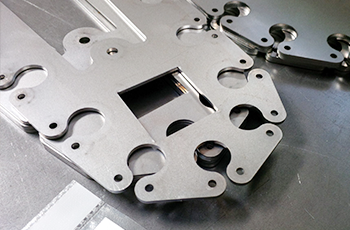

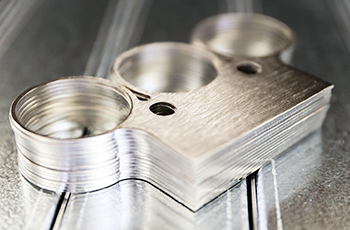

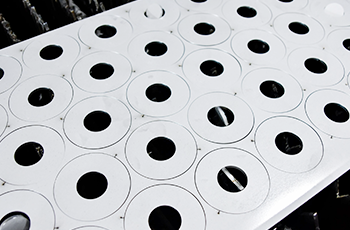

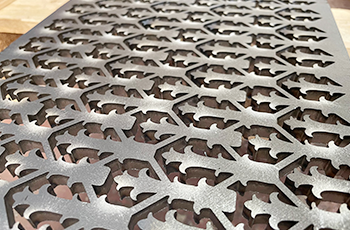

Application of Laser Cutting Machines

Why Choose Us

Cutting-Edge Technology

Every Faster Laser machine is built with the latest advancements, ensuring precise cuts, faster operation speeds, and the ability to handle complex designs effortlessly.

Superior Build Quality

We use only premium-grade materials and components, ensuring that every machine delivers consistent performance and maintains durability under heavy use.

Customized Solutions

Our team works closely with each customer to develop tailored laser cutting solutions that meet specific production needs and business objectives.

Comprehensive Support

Faster Laser provides thorough training, responsive technical support, and ongoing maintenance services to keep your machines running at peak efficiency.

Cost-Effective Investment

We offer high-quality laser cutting machines at competitive prices, ensuring you get maximum performance and long-term value from your investment.

Proven Industry Experience

With years of expertise and a strong global client base, Faster Laser has built a reputation for reliability, innovation, and customer satisfaction.

Laser Cutting Machines VS Other Cutting Machines

| Comparison Item | Laser Cutting Machine | Plasma Cutting Machine | Waterjet Cutting Machine | Flame Cutting Machine |

|---|---|---|---|---|

| Cutting Precision | Extremely high | Moderate | High | Low |

| Material Range | Metals, non-metals, composites | Mostly metals | Almost all materials | Primarily thick metals |

| Cutting Speed | Fast | Very fast | Moderate | Slow |

| Edge Quality | Smooth, clean edges | Rougher edges | Very smooth | Rough, oxidized edges |

| Heat-Affected Zone | Very small | Large | None | Large |

| Thickness Capability | Medium to thick | Thick materials | Very thick materials | Very thick materials |

| Operating Cost | Moderate | Low | High | Low |

| Maintenance Requirement | Low | Medium | High | Low |

| Environmental Impact | Low emissions | High emissions | High water usage, abrasive waste | High emissions |

| Initial Investment | Medium to high | Low | Very high | Low |

| Automation Integration | Easy | Moderate | Moderate | Difficult |

| Noise Level | Low | High | Low | High |

| Accuracy for Fine Details | Excellent | Poor | Excellent | Poor |

| Energy Consumption | Moderate | High | Very high | High |

| Typical Applications | Precision parts, electronics, signage | Construction, automotive | Aerospace, stone cutting | Heavy metal cutting |

Customer Testimonials

Related Resources

Laser Cutting VS Plasma Cutting: Which Is Better

Explore the differences between laser cutting and plasma cutting, including their working principles, applications, advantages, and limitations to help you choose the best method for your needs.

Frequently Asked Questions

How Much Do Laser-Cutting Machines Cost?

- CO2 Laser Cutting Machines

- CO2 laser cutting machines typically range in price from $3,100 to $16,000. These machines are widely used for cutting and engraving non-metallic materials such as wood, acrylic, plastic, leather, and glass. They use a gas laser that includes carbon dioxide, which is energized by electricity to produce the laser beam. CO2 lasers are ideal for smaller workshops, signage makers, and hobbyists due to their relatively low cost and versatility with organic materials.

- The lower end of the price range usually includes compact desktop models with lower power outputs (often 40W to 80W). These are suitable for lighter tasks like engraving or cutting thin materials. Higher-end CO2 laser cutting machines, closer to the $16,000 mark, often feature larger working areas, more powerful lasers (100W to 150W+), better cooling systems, and higher precision. These are better suited for businesses that need reliable, daily production capacity.

- Fiber Laser Cutting Machines

- Fiber laser cutting machines are significantly more expensive, with prices ranging from $25,000 to $350,000. These machines are designed primarily for cutting metals — including steel, aluminum, brass, and copper — with high speed and accuracy. They use a solid-state laser that is delivered through a fiber optic cable, which makes them more energy-efficient and suitable for industrial applications.

- At the lower end of this range (around $25,000 to $60,000), entry-level fiber lasers with moderate power (around 1kW to 2kW), often used by small metalworking shops or for prototyping. Machines in the mid-range ($60,000 to $150,000) typically offer more powerful lasers (3kW to 6kW), faster cutting speeds, better automation features, and are often part of more integrated production lines. The highest-end models, which can exceed $300,000, are advanced industrial machines built for high-volume production. These often include features like automatic loading/unloading, enclosed cutting areas, and software integration for precision manufacturing.

What Should I Know Before Buying Laser-Cutting Machines?

- Understand What Materials You’ll Be Cutting

- Different laser types are suited to different materials. Using the wrong laser type for your materials will limit your results and could damage the machine or pose safety risks.

- CO2 lasers are excellent for non-metals: wood, acrylic, leather, cardboard, paper, rubber, and some plastics. They can also engrave on glass and stone, but not cut metal effectively.

- Fiber lasers are designed specifically for metals, including stainless steel, aluminum, brass, copper, and carbon steel. They’re not ideal for wood or plastic.

- Laser Power and Performance

- Laser power (measured in watts) determines how deeply and fast a material can be cut. More power equals deeper cuts and faster speeds. Don’t buy more power than you need—it drives up costs (both upfront and operating) and may be unnecessary for your workflow.

- CO2 lasers typically range from 40W to 600W. 40W-150W suitable for engraving or cutting thin materials (up to 5 mm acrylic or wood). 150W-600W handles thicker materials and faster production.

- Fiber lasers start at around 1500W and can exceed 40,000W. 2kW-6kW can cut metals up to 6-10 mm thick, depending on type. 12kW-40kW industrial-level production, cuts thicker metals faster with cleaner edges.

- Work Area (Bed Size)

- Laser cutting machines come in different sizes. The size of the machine’s working area affects what you can cut.

- Consider your material sizes and how much cutting you’ll do at once. A larger bed size means you can process more material in a single pass.

- Precision, Accuracy, and Software Features

- If you need fine work (e.g., engraving, intricate patterns), look for: high-resolution optics (measured in DPI (dots per inch)), autofocus capabilities (to ensure consistent depth and clarity), stable motion systems (to ensure smooth, precise movement).

- Software is also important. Some machines come with proprietary software, but this limits your design flexibility. Some machines are compatible with common programs like LightBurn, CorelDRAW, AutoCAD, or Adobe Illustrator. You need to make sure the machine accepts standard file formats (SVG, DXF, AI, etc.). The better the software integration, the smoother your workflow from design to production.

- Cooling System Requirements

- Lasers generate heat, and overheating can lead to damage or reduced lifespan. CO2 lasers often require external water chillers. Basic air-cooled setups may not be enough for high-wattage models. Fiber lasers usually have integrated or industrial chillers due to the higher power output.

- Make sure you account for cooling space and cost in your setup.

- Ventilation and Exhaust Systems

- Cutting and engraving produce smoke, fumes, and sometimes toxic gases. Proper ventilation is essential, such as installing exhaust fans and ductwork to move the fumes outside. Also, avoid cutting PVC or vinyl materials, which release harmful chlorine when laser cut.

- Machine Durability, Support, and Maintenance

- Laser cutting machines are mechanical and optical systems that require regular maintenance. For example, clean lenses, check belts, add coolant, adjust mirrors, etc.

- Expect to need to replace lenses, mirrors, nozzles, and even laser sources over time.

- It is recommended to buy laser cutting machines from brands or dealers that provide fast support, detailed documentation, and spare parts supply. Cheap machines from unknown brands may save money upfront, but the lack of support may cost you more later.

- Total Cost of Ownership

- Don’t just focus on the sticker price. Consider the following: machine cost, shipping and tariffs (especially for imported models), installation and training, software licenses, consumables (mirrors, lenses, nozzles), maintenance and replacement parts, power consumption, downtime costs (if support is slow). A cheap machine without support can lead to costly mistakes.

- Space, Power, and Environment

- Make sure your workspace has enough physical space to accommodate the machine, cooling system, and ventilation system.

- Make sure you have the right power source. Some machines require 220V or three-phase power.

- Make sure the room is temperature-controlled and dust-free. Laser cutting machines perform best in a clean, dry environment.

What Are The Disadvantages of Laser-Cutting Machines?

- High Initial Cost: Laser-cutting machines, particularly fiber lasers, come with a steep upfront investment. CO2 laser cutting machines range from $3,000 to $16,000, while fiber lasers start at $25,000 and can exceed $300,000. This doesn’t include additional equipment like cooling systems, ventilation, or specialized software. For small businesses or individuals, this high cost can be a major barrier to entry.

- Ongoing Maintenance and Operating Costs: These machines require consistent upkeep to function properly. CO2 lasers need regular alignment of mirrors, cleaning of lenses, and eventual replacement of the laser tube. Fiber lasers have fewer moving parts but still require cleaning and maintenance. Beyond mechanical upkeep, you’ll need to budget for electricity, assist gases (for metal cutting), software updates, and replacement parts like nozzles or belts. Neglecting maintenance can shorten the machine’s lifespan or lead to costly breakdowns.

- Material Limitations: Each laser type has strict material constraints. CO2 lasers are great for non-metals but struggle with metals unless heavily modified. Fiber lasers are excellent for metals but are ineffective on transparent or organic materials like wood or acrylic. Some materials—especially PVC and vinyl—are dangerous to cut with any laser, as they release toxic gases that can harm users and damage the machine. This limits versatility and demands careful material selection.

- Health and Safety Risks: Laser-cutting machines pose real health and safety hazards. Cutting generates smoke and fumes that may contain harmful chemicals, especially when working with treated woods or plastics. Without proper ventilation or filtration systems, exposure can cause respiratory issues. High-power lasers also present burn risks and potential eye damage if safety covers or protocols are bypassed. Operators must follow strict safety procedures, and the work environment needs to be properly equipped.

- Size and Space Requirements: Laser machines can be large and bulky, especially industrial models. You need enough space not just for the machine itself, but also for safe access, material loading and unloading, cooling equipment, and ventilation systems. Machines with large bed sizes may also require reinforced flooring and high-clearance areas. For smaller workshops or home setups, space limitations can be a significant issue.

- Energy Consumption: Laser-cutting machines consume substantial energy. High-wattage CO2 and fiber lasers, along with their cooling systems and ventilation equipment, lead to high electricity usage. This is especially true for machines operating at an industrial scale. Some units require 220V or even three-phase power, which may necessitate electrical upgrades to your workspace. Over time, energy costs can significantly affect your operating budget.

- Learning Curve and Technical Skill Required: Laser-cutting machines are not beginner-friendly without some learning. You’ll need to understand design software (like LightBurn or CorelDRAW), file preparation, vector graphics, focus calibration, speed and power settings, and safety procedures. Mistakes in any of these areas can lead to poor-quality results, wasted material, or damage to the machine. Even machines marketed as “user-friendly” require time and effort to master.

- Slow Performance on Thick Materials: While lasers are fast and precise with thin materials, cutting thick materials is slower and may require multiple passes. This affects productivity, especially in high-volume environments. In some cases, other cutting methods like waterjet or plasma cutting may be more efficient for heavy-duty work. Overly thick materials may also require higher wattage lasers, which increases cost and energy usage.

- Setup Complexity: Buying the machine is only the first step. Proper setup involves installing ventilation or exhaust systems, connecting external chillers (for CO₂ lasers), ensuring proper grounding and power supply, and calibrating components. Larger or imported machines may arrive disassembled, requiring technical know-how or professional installation. A poorly installed machine can be dangerous or perform poorly, so setup should not be rushed or overlooked.

- Limited Multitasking: Most laser-cutting machines process one job at a time. While high-end models may offer automation or queuing systems, many entry-level or mid-range machines are limited to single-task operation. This can slow down production and reduce overall workflow efficiency, particularly if your work requires frequent material changes or multiple design variations. Multitasking is generally not a strength of laser systems compared to CNC routers or multitool fabrication machines.

How Thick Can Laser-Cutting Machines Cut?

- Fiber Laser Cutting Machines (For metals)

- Carbon Steel: Up to 25-50 mm, depending on power (e.g., 12kW-40kW machines)

- Stainless Steel: Up to 30 mm with high-power lasers

- Aluminum: Up to 30 mm, though cutting quality may decrease with thickness

- Brass/Copper: Up to 10-15 mm, with powerful machines and proper gas assist

- CO2 Laser Cutting Machines (For non-metals)

- Acrylic: Up to 30-40 mm (with high power like 300W+)

- Wood/MDF: Up to 20-25 mm, depending on density and moisture

- Leather/Fabric/Paper: Thin materials, usually under 10 mm, cut very easily

- Plastic (non-toxic types): Up to 20-25 mm, depending on type

What Is The Power Consumption of Laser-Cutting Machines?

- Fiber Laser Cutting Machines

- 1500W: Total power consumption ~8-10 kW

- 2000W: Total power consumption ~10-12 kW

- 3000W: Total power consumption ~12-18 kW

- 6000W: Total power consumption ~20-30 kW

- 12000W: Total power consumption ~30-40 kW

- 20000W: Total power consumption ~45-55 kW

- 30000W: Total power consumption ~60-75 kW

- 40000W: Total power consumption ~75-90+ kW

- These figures include the laser generator, water chiller, servo motors, control system, and air/gas assist systems. Fiber lasers are energy-efficient relative to their cutting performance, especially for metal processing.

- CO2 Laser Cutting Machines

- 60W: Total power consumption ~500-700 W

- 80W: Total power consumption ~600-900 W

- 90W: Total power consumption ~800-1000 W

- 100W: Total power consumption ~1.0-2 kW

- 130W: Total power consumption ~1.2-6 kW

- 150W: Total power consumption ~1.5-0 kW

- 180W: Total power consumption ~2.0-5 kW

- 220W: Total power consumption ~2.5-5 kW

- 300W: Total power consumption ~3.5-0 kW

- 500W: Total power consumption ~6.0-0 kW

- 600W: Total power consumption ~8.0-0 kW

- These values include the laser tube, power supply, chiller (for cooling), controller, and exhaust system. CO2 lasers use more energy per watt of laser output than fiber lasers and are best suited for cutting and engraving non-metal materials.

Why Are Laser-Cutting Machines So Expensive?

- Laser Source Technology

- The laser generator is one of the most expensive components.

- Fiber lasers use advanced solid-state technology with high beam quality and long lifespan, but the laser modules (especially at 6kW, 12kW, or higher) are costly to manufacture.

- CO2 lasers use gas-filled tubes with mirrors and high-voltage systems, which also involve precise engineering and materials.

- The higher the power rating, the more expensive the laser source, especially for industrial-grade cutting performance.

- Precision Components and Motion Systems

- Laser cutting machines require high-precision motors, linear guides, servo drives, and CNC controllers.

- These components ensure accurate positioning, fast cutting speeds, and repeatable performance.

- High-end machines use closed-loop systems and advanced motion controllers that raise the price significantly.

- Any slight error in alignment or movement can ruin the cut, so build quality and tolerance standards must be very high.

- Cooling and Safety Systems

- Laser-cutting machines need integrated or external cooling systems (especially CO2 laser cutting machines).

- Fiber lasers often require industrial chillers to maintain laser head temperatures during continuous operation.

- Proper safety features (light enclosures, interlocks, protective glass) are also essential and regulated, adding to the cost.

- Reliable cooling and safety systems are necessary to prevent overheating, ensure operator safety, and prolong machine life.

- Software and Automation

- Modern laser cutting machines come with advanced control software, nesting algorithms, and automation options.

- High-end software features (like automatic focus, intelligent path planning, CAD/CAM integration) increase machine productivity but add licensing and development costs.

- Optional add-ons like automatic material loading, real-time diagnostics, and remote monitoring raise the price further.

- These features reduce labor costs but require a more complex and costly machine architecture.

- Build Quality and Industrial Design

- Industrial-grade machines are built to withstand heavy-duty use.

- They are made from reinforced steel frames, vibration-resistant beds, and wear-resistant drive systems.

- Brand reputation, warranty, and support infrastructure also affect pricing.

- High-quality machines are engineered for reliability over thousands of hours of operation, which justifies a higher price.

- Import, Shipping, and Compliance Costs

- Laser machines are heavy and complex, making international shipping costly.

- Machines must comply with electrical, laser safety, and emissions standards (e.g., CE, ISO, FDA), which involve testing and certification.

- Import duties and taxes also factor into the final price, especially for machines imported from Europe or Asia.

- R&D and Brand Value

- Manufacturers invest heavily in research and development to improve cutting speed, edge quality, energy efficiency, and ease of use.

- Well-known brands charge more because of their proven reliability and innovation.

- You also pay for faster support, better documentation, and long-term availability of parts and service.

What Are The Hazards of Laser-Cutting Machines?

- Laser Radiation

- Laser cutting machines emit intense, focused light that can be hazardous to human tissue.

- CO2 lasers emit infrared radiation (10.6 µm), which can damage skin and the cornea.

- Fiber lasers emit at shorter wavelengths (typically around 1 µm), which can penetrate deeper into the eye and are especially dangerous to the retina.

- Exposure to direct or reflected beams can result in eye injury or skin burns.

- Laser safety goggles, machine enclosures, and interlocks are essential to reduce this risk.

- Fire Risk

- Laser cutting generates high temperatures, especially when cutting wood, paper, plastic, or textiles.

- Flammable materials can catch fire quickly if left unattended.

- Poor air circulation, dust buildup, or improper settings can worsen the risk.

- A fire extinguisher rated for electrical and flammable materials should be kept nearby, and the machine should never be left running unattended.

- Toxic Fumes and Gases

- Laser cutting vaporizes material, which can release harmful gases and particles.

- PVC and vinyl release chlorine gas, which is toxic and corrosive.

- Acrylics, MDF, painted surfaces, and other synthetics can emit formaldehyde, benzene, and carbon monoxide.

- Inadequate ventilation or filtration can expose operators to respiratory hazards or long-term health risks.

- Proper fume extraction, filters, and avoiding hazardous materials are critical safety measures.

- Mechanical Hazards

- Laser machines contain moving parts like gantries, motors, and belt systems.

- Accidental entrapment or pinching can cause cuts, bruises, or crushed fingers.

- Open belts or unguarded gears can snag clothing or hands if safety procedures are ignored.

- Operators should avoid reaching inside while the machine is active and ensure guards are in place.

- Electrical Hazards

- High-powered lasers and associated equipment run on powerful electrical systems.

- Faulty wiring, poor grounding, or moisture exposure can lead to shocks or electrocution.

- Unauthorized repairs or bypassing safety switches increase the risk.

- All electrical maintenance should be performed by trained personnel following lockout/tagout procedures.

- Noise and Vibration

- While generally not as loud as other industrial machines, laser cutting machines, especially when paired with high-pressure assist gas, can produce loud hissing or mechanical noise.

- Long-term exposure may lead to hearing damage.

- Vibration from large machines can cause strain or fatigue in poorly isolated setups.

- Hearing protection and proper machine mounting can help mitigate these risks.

- Beam Reflections (Metal Cutting)

- When cutting reflective metals like aluminum, brass, or copper, the laser beam can reflect and become hazardous.

- Improper setup or lack of beam traps can lead to uncontrolled reflections, posing safety threats to equipment and users.

- Fiber lasers are especially prone to reflection hazards due to their shorter wavelength.

- Anti-reflective coatings and proper focus settings are essential when cutting metals.

What Is The Operating Cost of Laser-Cutting Machines?

- Electricity Consumption: Laser cutting machines, especially high-powered CO₂ or fiber lasers, consume a lot of electricity. A typical industrial laser cutting machine may use between 3 kW and 15 kW, depending on power rating and workload. Continuous operation can lead to electricity costs ranging from $2 to $15 per hour or more, depending on local utility rates.

- Assist Gases: Many machines use assist gases like oxygen, nitrogen, or compressed air to improve cut quality and remove molten material. The cost varies by gas type and purity. For example, nitrogen for clean stainless steel cutting can cost $0.50 to $3 per hour, while oxygen is generally cheaper but affects material finish.

- Maintenance and Consumables: Routine maintenance includes replacing optics, lenses, mirrors, nozzles, filters, and cooling fluids. These costs add up over time. Consumables might cost $1,000-$5,000 annually, depending on usage. Unexpected repairs can increase this.

- Labor and Training: Skilled operators are essential for safe and efficient machine use. Operator wages, plus training time or certification, can represent a significant part of ongoing costs, especially in industrial settings.

- Software and Licensing: Many machines come with proprietary software for design and control. While basic packages are often included, advanced features or CAD/CAM integrations may require separate licenses or subscriptions.

- Ventilation and Fume Extraction: Safe operation requires proper fume extraction systems, which may have filters that need regular replacement. Operating and maintaining these systems adds several hundred to a few thousand dollars per year.

- Depreciation and Financing: Laser cutting machines are a major capital investment, ranging from $5,000 to over $500,000. Financing, insurance, and depreciation (especially for business accounting) are important financial factors over the machine’s life.

- Facility Requirements: Large machines may require dedicated space with structural support, ventilation, and climate control. Modifying a facility can create upfront or ongoing costs.