Product Introduction

Types of Pulsed Laser Cleaning Machines

-

FQP Laser Cleaning Machine

Rated 4.75 out of 5$7,280.00 – $84,500.00Price range: $7,280.00 through $84,500.00 Select options This product has multiple variants. The options may be chosen on the product page -

FQP-L Laser Cleaning Machine

Rated 4.63 out of 5$8,060.00 – $21,450.00Price range: $8,060.00 through $21,450.00 Select options This product has multiple variants. The options may be chosen on the product page -

FQP-B Laser Cleaning Machine

Rated 5.00 out of 5$8,450.00 – $11,440.00Price range: $8,450.00 through $11,440.00 Select options This product has multiple variants. The options may be chosen on the product page

Application of Pulsed Laser Cleaning Machines

Why Choose Us

Industrial-Grade Reliability

Our laser cleaning machines are built with premium components and tested to perform in tough industrial environments with minimal downtime.

Eco-Friendly Technology

We offer a dry, chemical-free cleaning solution that reduces environmental impact and eliminates the need for hazardous waste disposal.

Consistent Cleaning Results

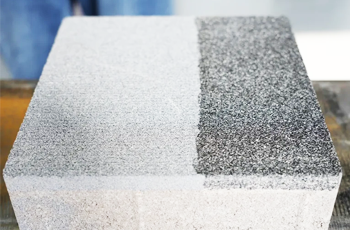

High-precision laser control delivers uniform cleaning without damaging the underlying material, even on delicate or complex surfaces.

Versatile Applications

Our systems clean rust, paint, oil, and oxidation on metal, stone, wood, and other materials across multiple industries.

Easy Operation and Integration

With plug-and-play functionality, ergonomic handheld designs, and optional automation, our machines fit seamlessly into any workflow.

Responsive Service and Support

Faster Laser provides training, technical guidance, and after-sales service to ensure smooth operation and long-term value.

Pulsed Laser Cleaning Machines VS Other Cleaning Machines

| Comparison Item | Pulsed Laser Cleaning Machine | Sandblasting Machine | High-Pressure Cleaning Machine | Dry Ice Blasting Machine |

|---|---|---|---|---|

| Cleaning Method | High-energy pulsed laser beam | Abrasive media propelled by compressed air | Water jet under high pressure | Dry ice pellets blasted at high velocity |

| Surface Damage Risk | Very low, ideal for delicate materials | High, can damage soft or detailed surfaces | Moderate, risk of erosion | Low, gentle on most materials |

| Precision Cleaning | Excellent, micron-level accuracy | Poor, not suitable for detailed work | Poor for precision cleaning | Moderate, better than sandblasting |

| Heat Affected Zone (HAZ) | Minimal, tightly controlled | N/A (abrasive-based) | N/A | Minimal |

| Suitable for Sensitive Materials | Yes | No | No | Yes |

| Environmental Impact | Very low, no chemicals or waste | High (dust, used abrasives) | Moderate (wastewater runoff) | Low, but requires ventilation |

| Waste Generation | None | High (media, dust, debris) | High (dirty water) | Low to moderate (sublimates to gas) |

| Chemical-Free Operation | Yes | No | Often yes, but depends on use | Yes |

| Cleaning Speed | Moderate to fast for precision areas | Fast for aggressive cleaning | Fast on broad, less-detailed surfaces | Moderate |

| Maintenance Requirements | Low | High (media handling, wear parts) | Moderate (pump, nozzle wear) | High (ice supply, nozzle care) |

| Operating Cost | Low (energy only, no consumables) | High (abrasive costs, PPE) | Moderate to high (water use, filters) | High (dry ice logistics) |

| Portability | High (compact and mobile options available) | Moderate | Moderate | Moderate |

| Safety Requirements | Laser safety goggles, enclosed space preferred | Full PPE (mask, gloves, goggles, suits) | Protective clothing, hearing protection | Gloves, goggles, ventilation |

| Setup Time | Quick (plug-and-play systems) | Moderate (media loading, pressure setup) | Moderate | Moderate (CO₂ supply setup) |

| Automation Compatibility | Excellent, easy integration with robotics | Limited | Limited | Limited |

Customer Testimonials

Related Resources

Laser Rust Removal VS Electrolytic Rust Removal

This article explains how laser rust removal and electrolytic rust removal work, compares their performance, costs, surface effects, and helps users choose the right method.

Laser Rust Removal VS Sandblasting Rust Removal

This article explores laser rust removal vs. sandblasting, comparing processes, costs, advantages, disadvantages, applications, and key factors in choosing the right method.

Frequently Asked Questions

What is Pulsed Laser Cleaning?

How Much Do Pulsed Laser Cleaning Machines Cost?

- 100W-200W Pulsed Laser Cleaning Machines: These entry-level models are well-suited for precision cleaning tasks such as removing thin oxide layers, delicate rust, soot, or contaminants from artwork, electronics, and sensitive equipment. Prices typically range from $7,500 to $15,000, making them affordable options for laboratories, restoration work, and small workshops.

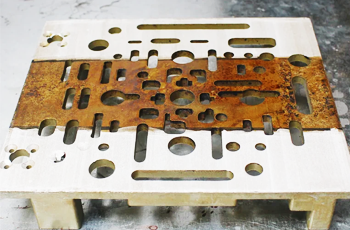

- 300W-500W Pulsed Laser Cleaning Machines: Mid-range systems offer greater pulse energy and faster cleaning speeds, allowing for the removal of paint, medium rust, and industrial residues on molds or metallic surfaces. These machines cost between $15,000 and $40,000 and are commonly used in automotive, aerospace, and general manufacturing industries where surface preservation is critical.

- 1000W-2000W Pulsed Laser Cleaning Machines: Designed for heavy-duty industrial applications, these high-powered systems are capable of removing thick coatings, corrosion, and multi-layer contaminants from complex components. With superior pulse control and deeper cleaning capability, their prices range from $40,000 to over $100,000. They are often used in aerospace, military, and nuclear sectors where high precision and reliability are essential.

What Are the Main Factors Affecting the Price of Pulsed Laser Cleaning Machines?

- Laser Power and Pulse Specifications

- Wattage (e.g., 100W to 2000W): Higher power levels allow for faster and deeper cleaning, but significantly increase cost.

- Pulse Energy and Duration: Machines with higher pulse energy and ultra-short pulse durations (e.g., nanosecond or picosecond) are more advanced and expensive.

- Repetition Rate (kHz): Higher frequency rates enable smoother and more uniform cleaning, which adds to the overall price.

- Cooling System

- Air-Cooled: More compact and cost-effective for low- to mid-power systems (up to ~300W).

- Water-Cooled: Required for higher power (500W and above); more efficient but adds to complexity, maintenance, and cost.

- Control System and Software

- Basic Controls: Standard manual interfaces are cheaper.

- Smart Interfaces and Automation Support: Advanced software with programmable cleaning paths, motion control, and user-friendly touchscreens increases the price.

- AI or Camera Integration: High-end systems may include visual recognition or automation features for precision cleaning.

- Design and Portability

- Handheld or Luggage Type: Compact designs for field work are often more expensive due to specialized engineering.

- Stationary or Desktop Units: More economical but less flexible for mobile or on-site use.

- Build Quality and Components

- Optics and Laser Source Quality: High-grade lenses, galvanometers, and imported laser sources (e.g., IPG, JPT) raise costs but enhance durability and beam quality.

- Protective Enclosures and Safety Features: Machines with fully enclosed housings, interlocks, and shielding are safer and more costly.

- Brand and Country of Origin

- Reputable Brands: European, Japanese, or U.S. brands typically cost more due to higher R&D, quality standards, and service networks.

- Local or Generic Brands: More budget-friendly but may vary in long-term reliability and after-sales support.

- Customization and Optional Features

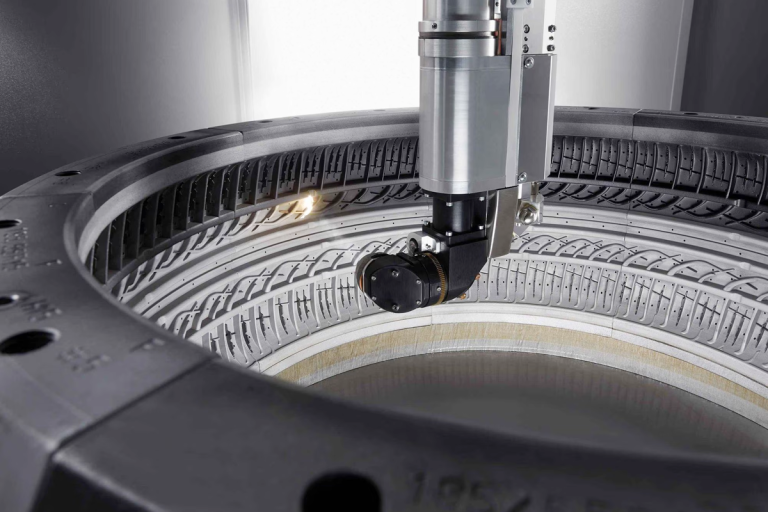

- Rotary Fixtures or Robotic Integration: Adds flexibility but significantly increases price.

- Fume Extraction Systems: Optional but essential for indoor or paint removal applications.

- Lens Sets or Cleaning Modes: Multiple nozzles or scanning patterns can raise the overall cost.

What Contaminants Can Be Removed by Pulsed Lasers?

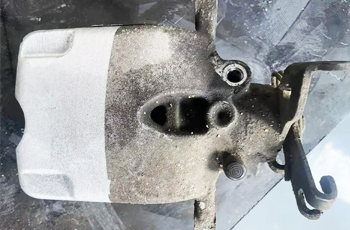

- Rust and Oxide Layers: Pulsed lasers can precisely remove surface rust (iron oxide) and oxidation layers from metals like steel, aluminum, and copper. The laser’s short pulses vaporize the oxide without overheating or warping the base material, making it ideal for restoring delicate or thin components.

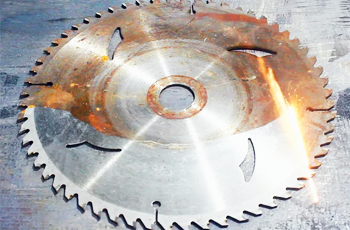

- Paint and Coatings: They are highly effective at removing industrial paint, powder coatings, and organic surface films from metals and composites. Pulsed lasers can strip paint layer by layer, allowing selective removal without damaging detailed patterns or sensitive substrates.

- Oil, Grease, and Residue: Pulsed lasers easily clean grease stains, oily films, and manufacturing residues (such as cutting fluids or stamping lubricants), especially in the aerospace, electronics, and automotive industries where contamination affects bonding or assembly.

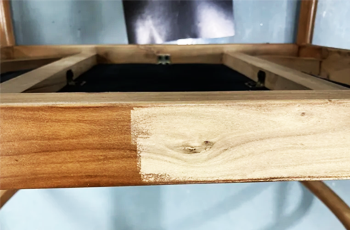

- Soot, Carbon, and Smoke Deposits: Used widely in cultural heritage restoration, pulsed lasers gently remove soot, smoke stains, and carbon deposits from stone, wood, marble, and brick without abrasives or chemicals.

- Anodization and Laser Oxide: Surface treatments like anodized layers, black laser oxides, and heat-affected zone discoloration (common in welding) can be precisely cleaned to restore a surface to its original finish without mechanical grinding.

- Adhesive and Glue Residues: Effective at eliminating tape glue, epoxy films, and label residues from metal or glass surfaces. Pulsed lasers remove adhesive without melting or smearing it across the workpiece.

- Thin Coatings and Films: They can strip protective films, polymer layers, or photoresists in electronics and semiconductor applications, critical for cleanrooms and high-tech environments.

- Mold, Biofilms, and Oxidized Debris: In food, medical, and mold cleaning industries, pulsed lasers can clean bacteria layers, biofilms, or calcified debris without using chemicals, making them ideal for hygienic or regulated environments.

How Does the Pulsed Duration Affect the Cleaning Results?

- Thermal Impact

- Shorter Pulse Durations (ps/fs): Deliver energy so fast that there’s little time for heat to spread, leading to minimal thermal damage. Ideal for delicate surfaces, electronics, or materials that deform easily.

- Longer Pulse Durations (ns): Allow more time for heat diffusion, increasing the risk of thermal stress or substrate discoloration. Better suited for robust surfaces or less sensitive materials.

- Cleaning Precision

- Shorter Pulses: Can ablate ultra-thin layers and offer higher precision, allowing selective cleaning (e.g., removing oxides without disturbing base metal).

- Longer Pulses: Clean larger areas more quickly but with less layer selectivity, which might affect fine details.

- Material Removal Efficiency

- Shorter Pulses: Have higher peak power, causing micro-explosions or plasma formation that lift contaminants efficiently with less residue.

- Longer Pulses: Use more thermal expansion and vaporization, which can melt or smear soft coatings if not carefully controlled.

- Surface Finish Quality

- Short Pulses: Produce cleaner finishes with minimal surface roughness, critical in optics, aerospace, and semiconductors.

- Long Pulses: May cause slight pitting, texture changes, or roughening, especially at higher energies.

What Are the Hazards of Pulsed Laser Cleaning?

- Eye Damage: Pulsed lasers emit concentrated beams, often in the invisible infrared spectrum (e.g., 1064 nm), which can cause permanent eye injury or blindness if viewed directly or through reflective surfaces. Because of their short pulse duration and high peak power, even brief exposure is dangerous. Proper laser safety goggles must always be worn.

- Skin Burns and Injuries: The high-energy pulses can cause instant skin burns or photothermal effects. Additionally, during cleaning, small particles or sparks can be ejected from the surface, leading to potential contact burns or cuts if the operator is too close or unprotected.

- Toxic Fume and Particle Inhalation: Pulsed laser ablation can release harmful vapors, dust, or volatile organic compounds (VOCs), especially when removing paint, rust, oil, or synthetic coatings. Inhalation of these byproducts can harm the respiratory system, and some fumes may be carcinogenic.

- Fire Risk: Certain materials, especially dry, dusty, or flammable coatings, can ignite under the laser beam. The pulsed energy may also trigger small explosions when trapped gases or pressurized residues are present.

- Equipment Damage from Reflections: Reflective surfaces like polished metals can redirect the laser beam, damaging optics, electronics, or even bouncing back into unintended directions, posing a safety threat to users and equipment.

- Noise Exposure: Some pulsed laser processes generate loud popping or cracking sounds due to micro-explosions during surface ablation. Prolonged exposure without hearing protection may affect hearing.

- Electrical Hazards: Like all laser equipment, pulsed laser systems involve high-voltage power supplies. Faulty wiring or improper handling can result in electrical shock or short circuits.

What Are the Disadvantages of Pulsed Laser Cleaning Machines?

- High Cost: Pulsed laser systems are typically more expensive than other cleaning methods. Entry-level machines start around $7,500, but industrial-grade systems with high pulse energy and precision features can exceed $100,000. This upfront investment may not be feasible for small-scale operations or budget-conscious buyers.

- Slower Cleaning Speed: Pulsed lasers excel at precision, but their material removal rate is slower compared to continuous lasers. For large surface areas or thick contaminants like heavy rust or multi-layer coatings, pulsed systems may take significantly more time to complete the task.

- Complex Maintenance and Operation: These machines require proper calibration of pulse energy, duration, and repetition rate to achieve optimal cleaning results. Cooling systems, sensitive optics, and control software demand regular upkeep, which can increase operational complexity and maintenance costs.

- Strict Safety Requirements: High-peak-power pulses can pose serious risks to eyes and skin. Operators must wear wavelength-specific laser safety goggles and follow strict safety protocols. Additional equipment, like fume extractors and beam enclosures, may be necessary to meet regulatory standards.

- Not Ideal for Thick or Tough Coatings: While pulsed lasers are excellent at removing thin layers or contaminants on delicate surfaces, they may struggle with thick paint, corrosion, or rough industrial coatings. In such cases, a high-power continuous laser or abrasive method may be more efficient.

- Size and Portability Limitations: Some high-power pulsed systems are large and require water-cooling units, making them less portable than suitcase-style or handheld continuous laser machines. This can limit their use in fieldwork or tight spaces.

What Is the Service Life of Pulsed Laser Cleaning Machines?

- Laser Source: Most pulsed laser cleaning machines use fiber lasers, which are known for their durability. High-quality sources from manufacturers like IPG, JPT, or Raycus typically offer a lifespan of 80,000 to 100,000 hours. This long operational time makes them ideal for both intermittent and continuous use, as long as operating conditions remain stable and within recommended parameters.

- Optical Components: The protective lenses and scanning optics can degrade faster due to exposure to dust, splatter, or misalignment. These parts typically require replacement every 6 to 12 months, depending on how often the machine is used and the cleanliness of the environment.

- Cooling System: Machines using air cooling tend to have fewer maintenance needs but may suffer from overheating under heavy use. Water-cooled machines require coolant replacement, filter cleaning, and pump servicing, with cooling components usually lasting 3 to 6 years.

- Galvanometer and Scanning Head: These mechanical parts, responsible for directing the laser beam, can last 5 to 8 years, but their performance may degrade over time if exposed to vibration, heat, or debris without regular maintenance.

- Control System and Software: These components are digital and wear-resistant. With regular updates and protected operation, they can remain effective for 8 to 10 years, often matching the machine’s full service life.

- Overall Machine Life: With proper operation, routine maintenance, and part replacement, a pulsed laser cleaning machine can reliably function for 8 to 10 years or more. High-end models with robust construction and preventive care may exceed this lifespan.