Product Introduction

Types of Continuous Laser Cleaning Machines

-

FQ Laser Cleaning Machine

Rated 4.63 out of 5$4,550.00 – $21,450.00Price range: $4,550.00 through $21,450.00 Select options This product has multiple variants. The options may be chosen on the product page -

FQ-P Laser Cleaning Machine

Rated 4.75 out of 5$4,810.00 – $21,710.00Price range: $4,810.00 through $21,710.00 Select options This product has multiple variants. The options may be chosen on the product page -

FQ-D Laser Cleaning Machine

Rated 5.00 out of 5$5,460.00 – $22,360.00Price range: $5,460.00 through $22,360.00 Select options This product has multiple variants. The options may be chosen on the product page

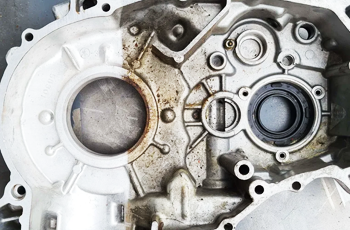

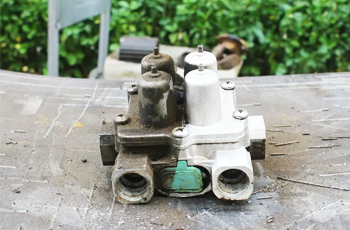

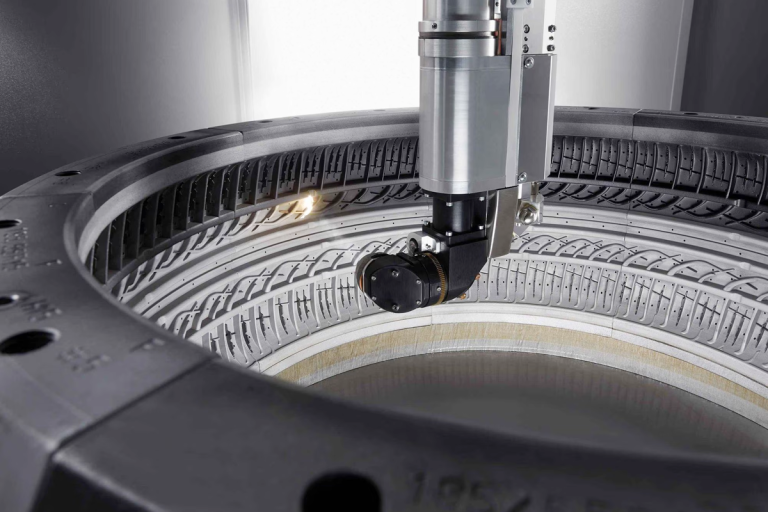

Application of Continuous Laser Cleaning Machines

Why Choose Us

Industrial-Grade Reliability

Our laser cleaning machines are built with premium components and tested to perform in tough industrial environments with minimal downtime.

Eco-Friendly Technology

We offer a dry, chemical-free cleaning solution that reduces environmental impact and eliminates the need for hazardous waste disposal.

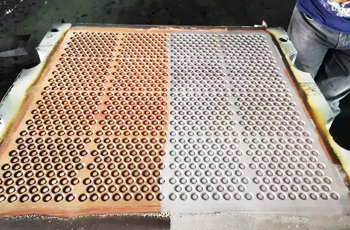

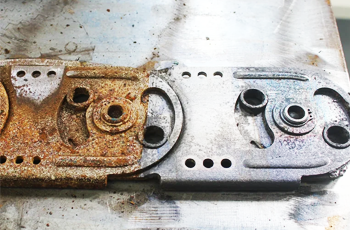

Consistent Cleaning Results

High-precision laser control delivers uniform cleaning without damaging the underlying material, even on delicate or complex surfaces.

Versatile Applications

Our systems clean rust, paint, oil, and oxidation on metal, stone, wood, and other materials across multiple industries.

Easy Operation and Integration

With plug-and-play functionality, ergonomic handheld designs, and optional automation, our machines fit seamlessly into any workflow.

Responsive Service and Support

Faster Laser provides training, technical guidance, and after-sales service to ensure smooth operation and long-term value.

Continuous Laser Cleaning Machines VS Other Cleaning Machines

| Comparison Item | Continuous Laser Cleaning Machine | Sandblasting Machine | High-Pressure Cleaning Machine | Dry Ice Blasting Machine |

|---|---|---|---|---|

| Cleaning Method | Continuous high-power laser beam | Abrasive particles propelled by compressed air | High-pressure water spray | Solid CO2 pellets accelerated at high speed |

| Cleaning Consistency | Very high, stable laser output | Variable, depends on media condition | Inconsistent on uneven surfaces | Moderate |

| Surface Damage Risk | Very low (non-contact, controlled energy) | High (abrasive impact) | Moderate (can erode soft materials) | Low |

| Environmental Impact | Very low, no secondary waste | High (dust, media waste, environmental dusting) | Moderate (wastewater, runoff) | Low, but CO2 release requires ventilation |

| Cleaning Speed | Fast and continuous | Fast but aggressive | Fast on broad, flat areas | Moderate |

| Precision Cleaning Capability | Excellent, fine control on small and large areas | Poor precision, not ideal for detailed surfaces | Poor for delicate or precision applications | Moderate |

| Consumables Required | None | Yes (sand, grit, etc.) | Yes (clean water, filters) | Yes (dry ice pellets) |

| Waste Generation | Minimal | High (spent media and dust) | High (dirty water) | Low to moderate (sublimation, particles) |

| Suitable for Automation | Yes, excellent for integration | Limited | Limited | Limited |

| Maintenance Requirements | Low | High (media replacement, nozzle wear) | Moderate (pump, hose maintenance) | High (nozzle, ice supply) |

| Surface Compatibility | Metal, stone, plastic, rubber, composite | Hard, durable surfaces only | Water-resistant surfaces only | Wide range, including sensitive surfaces |

| Operating Cost | Low (energy only, no consumables) | High (media cost, disposal, PPE) | Moderate (water usage, wear parts) | High (CO2 supply, maintenance) |

| Portability | High (available in mobile formats) | Low to moderate | Moderate | Moderate |

| Setup Time | Short (plug-and-play systems) | Moderate to long | Moderate | Moderate to long |

| Health & Safety Risks | Low (with proper shielding and PPE) | High (inhalation, eye protection required) | Moderate (slip, noise, flying debris) | Moderate (cold burns, ventilation required) |

Customer Testimonials

Related Resources

Laser Rust Removal VS Sandblasting Rust Removal

This article compares laser rust removal and sandblasting rust removal, exploring the methods, advantages, disadvantages, applications, and factors to consider when choosing between the two.

Frequently Asked Questions

What is Continuous Laser Cleaning?

- A continuous laser beam is directed onto the surface using a handheld or automated laser head.

- The laser energy rapidly heats and vaporizes the unwanted layer (rust, paint, etc.), separating it from the substrate.

- A protective air or inert gas shield may be used to prevent oxidation and assist in debris removal.

- The cleaned surface is left bare, often without damage to the underlying material if properly controlled.

What Laser Powers Can Be Selected for Continuous Laser Cleaning Machines?

- 1500W Continuous Laser Cleaning Machine: This power level offers a balanced solution for medium-duty cleaning jobs. It can effectively remove surface rust, thin paint layers, and oxide films from metals like steel and iron. It’s a popular choice in workshops, maintenance depots, and for automotive part restoration. With moderate energy output, it is efficient for daily use while remaining cost-effective and safe for a range of applications.

- 2000W Continuous Laser Cleaning Machine: With higher energy delivery, 2000W machines are suitable for more demanding tasks such as cleaning weld seams, thicker rust, industrial paints, and stubborn coatings. They provide faster cleaning speeds and deeper penetration compared to 1500W units, making them ideal for medium- to large-scale operations in heavy machinery, railroads, or steel fabrication.

- 3000W Continuous Laser Cleaning Machine: This power range is designed for heavy-duty industrial cleaning, handling thick corrosion, multi-layer paint systems, and hardened deposits. It is often used in environments like shipyards, power plants, and oil pipelines, where both cleaning speed and thoroughness are critical. The 3000W laser ensures efficient stripping over large surface areas with minimal downtime.

- 6000W Continuous Laser Cleaning Machine: This is the highest commonly used power level for continuous laser cleaning. It is capable of removing the most stubborn industrial coatings, deep oxidation, and thick contaminants quickly and efficiently. It’s often deployed in large infrastructure projects such as bridge maintenance, ship hull cleaning, and steel construction plants. Due to its high energy output, it requires advanced cooling systems, trained operators, and strict safety protocols.

How Do I Determine Which Power Level Will Meet My Cleaning Application?

- Type and Thickness of Contaminant: Thicker and more stubborn layers, such as heavy rust, multi-layer industrial paint, or thick oxides, require higher power (3000W-6000W) for complete removal. In contrast, light surface rust, oil films, or thin coatings can be effectively cleaned with 1500W or 2000W machines.

- Material Sensitivity: Softer or heat-sensitive materials like aluminum or coated surfaces may get damaged by high-power lasers. In such cases, lower-power options like 1500W or 2000W are better suited to avoid thermal distortion or surface damage.

- Surface Area to be Cleaned: For large surface areas or high-volume industrial tasks (e.g., ship hulls, factory equipment), higher power levels like 3000W or 6000W allow faster processing and greater productivity. For small, localized cleaning jobs, 1500W-2000W offers sufficient performance without unnecessary energy consumption.

- Cleaning Speed Requirements: If turnaround time is critical, such as in production lines or field services, higher power levels offer faster cleaning speeds and deeper removal. A 6000W machine, for example, can clean thick corrosion layers in a fraction of the time it takes a 1500W system.

- Portability and Power Infrastructure: High-power systems (especially 3000W and 6000W) are larger, heavier, and require more robust electrical and cooling support. If mobility is a priority, such as for onsite maintenance or remote operations, 1500W and 2000W machines offer more flexible deployment.

- Budget Considerations: Higher power machines are more expensive in terms of initial cost, power consumption, and cooling requirements. If your cleaning tasks are not heavy-duty, opting for a 1500W or 2000W model can reduce both capital and operational costs.

How Does Continuous Laser Cleaning Remove Surface Contaminants?

- Focused Laser Beam Energy: A continuous wave (CW) laser emits a steady, high-power beam that is directed at the contaminated surface. This concentrated energy rapidly heats the surface contaminant, such as rust, paint, or oxide, without significant delay, thanks to the uninterrupted nature of the beam.

- Thermal Expansion and Vaporization: Different materials absorb laser energy at different rates. Contaminants like corrosion or paint typically absorb laser energy more efficiently than the base metal. This differential absorption causes the contaminant to heat up rapidly, leading to thermal expansion, vaporization, or sublimation. The sudden energy transfer breaks the bond between the contaminant and the substrate, effectively lifting it off.

- Shockwave and Particle Ejection: The intense heat can create small plasma bursts or micro-explosions at the contaminant layer, especially if moisture or volatile compounds are present. This results in shockwaves that help blast away loosened particles from the surface, ensuring thorough cleaning.

- No Damage to Substrate (When Controlled Properly): Continuous laser systems can be precisely adjusted in terms of power, scan speed, and focus. When properly configured, the laser removes only the unwanted layer while preserving the integrity of the underlying material, even for sensitive metals.

- Debris Removal with Air Assist or Suction: To keep the cleaned surface visible and prevent redeposition, an air nozzle or vacuum system is often used in tandem to blow away or extract particles as they’re removed, leaving the substrate clean and ready for further processing.

What Materials Can Be Cleaned With Continuous Laser Cleaning Machines?

- Metals (Most Suitable)

- Carbon Steel and Stainless Steel: These metals are ideal for continuous laser cleaning. The laser removes rust, oxides, and coatings without damaging the underlying surface, especially when parameters are properly set.

- Aluminum and Aluminum Alloys: Can be cleaned of surface oxidation, coatings, and grease. Care must be taken with power levels to avoid melting or surface deformation due to aluminum’s high thermal conductivity.

- Copper and Brass: Although highly reflective, these metals can still be cleaned with high-power continuous lasers if the beam is correctly focused and wavelength-optimized.

- Titanium and Nickel Alloys: Common in aerospace and medical fields, these can be laser cleaned to remove oxides, contaminants, or coatings without introducing mechanical stress.

- Other Suitable Materials

- Cast Iron and Tool Steel: Heavy-duty equipment often made from these materials can be effectively cleaned of rust, scale, and industrial buildup.

- Welded Joints and Heat-Affected Zones: Continuous lasers are excellent for pre-weld and post-weld cleaning to remove oxides and improve weld quality.

- Materials Cleaned with Caution

- Stone and Concrete (Selective Use): Lasers can clean soot, graffiti, or biological growth from monuments or surfaces, but prolonged exposure can cause surface melting or color change.

- Glass and Ceramics (Surface Only): Can be laser cleaned for residues or coatings, but the brittle nature and reflectivity of these materials require very controlled parameters to avoid cracking or damage.

- Materials to Avoid

- Plastics and Polymers: Most plastics are heat-sensitive and may melt or release toxic fumes under continuous laser exposure. Pulsed lasers are better suited for such materials.

- Painted or Coated Wood: The organic and combustible nature of wood makes it risky to clean with a high-power continuous laser, which can char or ignite the surface.

Does Continuous Laser Cleaning Require The Use Of Auxiliary Gas?

- When Auxiliary Gas Is Used

- Improved Cleaning Efficiency: Compressed air or inert gases (like nitrogen or argon) help blow away molten particles, rust, and dust as the laser ablates the surface. This keeps the beam path clear and increases cleaning effectiveness.

- Oxidation Prevention: When cleaning reactive metals (like aluminum or titanium), inert gases like nitrogen or argon prevent surface reoxidation during and after cleaning, especially useful for welding preparation.

- Heat Dissipation: Gas flow helps cool the surface, reducing the risk of thermal damage to sensitive materials or thin workpieces.

- Debris Control: A gas-assist system removes particles and fumes from the working area, preventing redeposition and minimizing contamination.

- Laser Optic Protection: Gas flow around the laser head forms a protective barrier, shielding the optics from back-splatter and particulate buildup.

- When Auxiliary Gas Is Not Necessary

- Light-duty cleaning, such as removing light rust or oil films from steel surfaces.

- Non-reactive metals, where oxidation is not a concern.

- Situations with built-in fume extraction, where particle removal is already optimized.

What Are the Safety Measures for Operating Continuous Laser Cleaning Machines?

- Wear Proper Laser Safety Gear

- Laser Safety Glasses: Always wear wavelength-specific laser goggles (typically 1064nm for fiber lasers) to protect your eyes from direct or reflected beams.

- Protective Clothing: Use flame-resistant clothing, gloves, and closed-toe shoes to shield yourself from hot particles or metal debris.

- Face Shield (if needed): When handling heavy rust or coatings, a full-face shield may provide additional protection from flying debris.

- Use Safety Enclosures and Barriers

- Protective Housing: Operate in a closed or semi-enclosed workspace to prevent stray beams from escaping.

- Laser Safety Curtains or Panels: If working in open areas, use certified barriers to contain the beam path.

- Emergency Stop and Interlocks

- Emergency Stop Button: Ensure all operators know where the emergency stop is located and how to use it in case of malfunction.

- Interlock Systems: Use safety interlocks to disable the laser when the protective enclosure is open or improperly closed.

- Avoid Direct and Reflected Exposure

- No Direct Viewing: Never look directly at the laser beam or reflections, even with safety glasses.

- Control Reflective Surfaces: Avoid using near shiny metals (like polished aluminum) that can reflect the beam unpredictably.

- Fume Extraction and Ventilation

- Proper Exhaust System: Install a fume extractor to remove smoke, vaporized particles, and potentially hazardous fumes.

- Air Filtration: Use filters to capture fine particles and volatile organic compounds (VOCs), especially when cleaning paints or coatings.

- Electrical and Equipment Safety

- Grounding and Inspections: Ensure the machine is properly grounded and inspect cables, cooling units, and connectors regularly.

- Avoid Unauthorized Modifications: Only certified technicians should service or alter the laser system.

- Operator Training and Signage

- Certified Training: Only trained and authorized personnel should operate the machine.

- Warning Signs: Display clear warning labels and “Laser in Use” signs to alert others nearby.

- Software and Access Control

- Password-Protected Controls: Limit machine access to prevent unauthorized use.

- Pre-Programmed Parameters: Avoid manual adjustments during operation unless necessary and verified.

How Do I Maintain Continuous Laser Cleaning Machines?

- Daily Cleaning and Inspection

- Clean the Laser Lens/Protective Window: Use a soft, lint-free cloth and lens-safe cleaning solution to remove dust or debris. Dirty optics can reduce laser efficiency or cause damage.

- Check for Debris Buildup: Inspect the nozzle, scanning head, and air outlets for rust particles, paint chips, or dust. Clean gently to avoid clogging.

- Wipe Down the Exterior: Keep the housing and control surfaces free of grease and dirt to prevent overheating and electrical issues.

- Maintain the Cooling System

- Check Water Levels: If your machine uses a water chiller, ensure the coolant is at the proper level and within the correct temperature range.

- Replace Coolant Regularly: Change the coolant every 3-6 months, or as recommended, to prevent algae, scale, or corrosion.

- Clean the Filter and Radiator: A blocked radiator or clogged filter can reduce cooling efficiency, risking overheating of the laser source.

- Electrical and Connection Checks

- Inspect Cables and Connectors: Look for wear, fraying, or loose connections in power and signal cables.

- Tighten Ground Wires: Ensure proper grounding to avoid electrical faults and static buildup.

- Monitor Power Supply Health: Check indicators for voltage fluctuations, overheating, or errors in the power unit.

- Software and System Diagnostics

- Run Self-Diagnostics: Use the built-in software tools to check system health, temperature, and laser output.

- Update Firmware: Keep software and firmware up to date for better performance and security.

- Back Up Parameters: Save configuration files in case settings need to be restored after service.

- Mechanical Parts Lubrication

- Lubricate Moving Parts: If your system includes a motorized gantry or scanning system, apply suitable lubricants to rails or bearings to reduce wear.

- Check for Alignment Drift: Periodically test beam alignment and scanning head calibration to maintain precision.

- Safety System Checks

- Test Emergency Stop Buttons: Confirm that all emergency stops and interlock functions work properly.

- Inspect Fume Extraction System: Change filters as needed and ensure ducting is free of obstructions for safe operation.

- Scheduled Professional Maintenance

- Annual Service Check: Have a certified technician inspect and calibrate the machine annually.

- Replace Worn Components: Replace laser heads, protective lenses, or scanner motors if signs of wear or decline in performance are observed.