Product Introduction

Types of Laser Cleaning Machines

-

FQ Laser Cleaning Machine

Rated 4.63 out of 5$4,550.00 – $21,450.00Price range: $4,550.00 through $21,450.00 Select options This product has multiple variants. The options may be chosen on the product page -

FQ-P Laser Cleaning Machine

Rated 4.75 out of 5$4,810.00 – $21,710.00Price range: $4,810.00 through $21,710.00 Select options This product has multiple variants. The options may be chosen on the product page -

FQ-D Laser Cleaning Machine

Rated 5.00 out of 5$5,460.00 – $22,360.00Price range: $5,460.00 through $22,360.00 Select options This product has multiple variants. The options may be chosen on the product page -

FQP Laser Cleaning Machine

Rated 4.75 out of 5$7,280.00 – $84,500.00Price range: $7,280.00 through $84,500.00 Select options This product has multiple variants. The options may be chosen on the product page -

FQP-L Laser Cleaning Machine

Rated 4.63 out of 5$8,060.00 – $21,450.00Price range: $8,060.00 through $21,450.00 Select options This product has multiple variants. The options may be chosen on the product page -

FQP-B Laser Cleaning Machine

Rated 5.00 out of 5$8,450.00 – $11,440.00Price range: $8,450.00 through $11,440.00 Select options This product has multiple variants. The options may be chosen on the product page

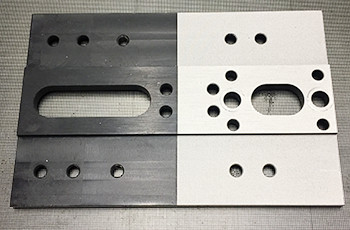

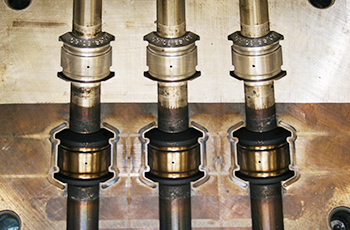

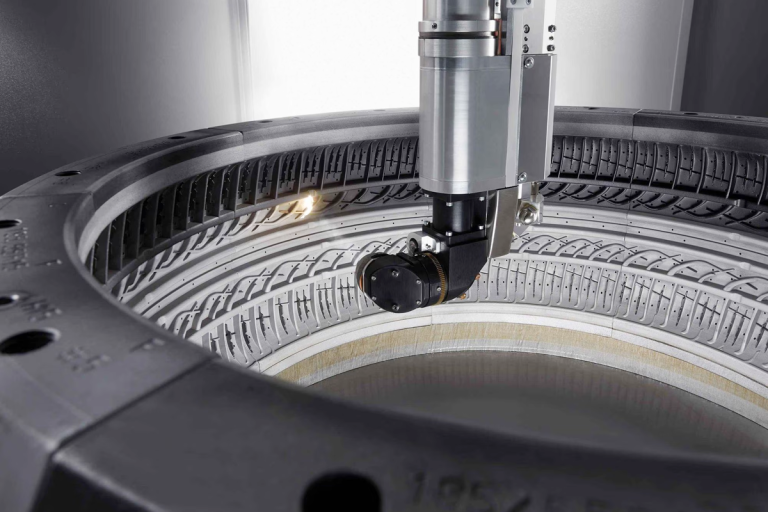

Application of Laser Cleaning Machines

Why Choose Us

Industrial-Grade Reliability

Our laser cleaning machines are built with premium components and tested to perform in tough industrial environments with minimal downtime.

Eco-Friendly Technology

We offer a dry, chemical-free cleaning solution that reduces environmental impact and eliminates the need for hazardous waste disposal.

Consistent Cleaning Results

High-precision laser control delivers uniform cleaning without damaging the underlying material, even on delicate or complex surfaces.

Versatile Applications

Our systems clean rust, paint, oil, and oxidation on metal, stone, wood, and other materials across multiple industries.

Easy Operation and Integration

With plug-and-play functionality, ergonomic handheld designs, and optional automation, our machines fit seamlessly into any workflow.

Responsive Service and Support

Faster Laser provides training, technical guidance, and after-sales service to ensure smooth operation and long-term value.

Laser Cleaning Machines VS Other Cleaning Machines

| Comparison Item | Laser Cleaning Machine | Sandblasting Machine | High-Pressure Cleaning Machine | Dry Ice Blasting Machine |

|---|---|---|---|---|

| Cleaning Method | High-energy laser beam | Abrasive blasting with sand or grit | High-pressure water spray | CO2 pellets are blasted at high speed |

| Surface Damage Risk | Very low (non-contact) | High (abrasive impact) | Moderate (erosion possible) | Low |

| Environmental Impact | Very low, no consumables | High (dust, abrasive waste) | Moderate (water runoff) | Low, but uses CO2 |

| Waste Generation | Minimal (no residue) | High (used media and dust) | High (dirty water) | Moderate (dry ice sublimates) |

| Cleaning Precision | Very high | Low to moderate | Low | Moderate |

| Substrate Compatibility | Metal, stone, wood, and delicate surfaces | Mainly metal and hard surfaces | Suitable for hard, water-tolerant surfaces | Metal, plastic, and electrical components |

| Chemical-Free | Yes | No | Often no | Yes |

| Operating Cost | Low (minimal consumables) | Moderate to high (abrasive media costs) | Moderate (water usage, filtration) | High (dry ice and equipment) |

| Maintenance Requirements | Low | High (nozzle, tank, media replacement) | Moderate (pump and filtration maintenance) | High (supply and wear parts) |

| Portability | High (compact, mobile options available) | Low to moderate | Moderate | Moderate |

| Automation Capability | Excellent (CNC/robotic integration possible) | Limited | Limited | Limited |

| Noise Level | Low | High | High | High |

| Safety Measures | Laser goggles and shielding | Dust masks, protective suits | Waterproof gear | Ventilation and PPE |

| Cleaning Speed | Fast for surface layers and precision areas | Fast but aggressive | Fast on large, flat areas | Moderate |

| Typical Applications | Rust, paint, oil, oxide removal, and delicate surfaces | Heavy rust, scale, and coatings on durable surfaces | Dirt, grease on machinery, and exterior surfaces | Mold, oil, and electrical component cleaning |

Customer Testimonials

Related Resources

Laser Rust Removal VS Electrolytic Rust Removal

This article explains how laser rust removal and electrolytic rust removal work, compares their performance, costs, surface effects, and helps users choose the right method.

Laser Rust Removal VS Sandblasting Rust Removal

This article explores laser rust removal vs. sandblasting, comparing processes, costs, advantages, disadvantages, applications, and key factors in choosing the right method.

Frequently Asked Questions

What Types Of Materials Can Be Cleaned With Laser Cleaning Machines?

- Metals and Alloys: Laser cleaning is most widely used for treating metal surfaces because metals absorb laser energy efficiently and resist thermal damage under controlled settings.

- Carbon Steel: Removes rust, paint, oxides, and coatings effectively

- Stainless Steel: Cleans weld seams, oxide layers, and surface contaminants without damaging the substrate

- Aluminum and Alloys: Removes anodizing, oxides, and paint (requires controlled settings due to reflectivity)

- Copper and Brass: Cleans corrosion, oxides, and dirt (may require high-power pulse lasers)

- Titanium and Nickel Alloys: Ideal for precision cleaning in aerospace and medical industries

- Stone and Masonry: Laser cleaning works well on cultural heritage restoration and industrial stone cleaning, especially when preserving delicate textures is crucial.

- Marble and Limestone: Removes soot and biological growth from monuments and sculptures

- Granite and Sandstone: Effective for removing graffiti and pollution crusts without abrasion

- Plastics (Limited Applications): Some high-durability plastics can be laser-cleaned, but care is essential to avoid surface melting or deformation.

- PTFE and PEEK: Can be laser-cleaned in industrial applications with low-power settings

- Note: Most general-purpose plastics are not suitable due to low melting points and the risk of toxic fume release

- Wood (Limited and Controlled Use): Laser cleaning is used primarily for restoration purposes. It can remove surface grime or paint layers from wooden sculptures or furniture.

- Hardwood Surfaces: Can be cleaned at very low power

- Note: High power may char or burn wood—testing and tuning are essential

- Glass and Ceramics (Selective Cleaning): Laser cleaning can remove coatings or contaminants without scratching the surface, useful in electronics and optics.

- Glass Panels: Removes adhesives, coatings, or labels

- Ceramic Surfaces: Cleans industrial residues or printed marks

- Other Surface Layers that Can Be Removed:

- Rust and Corrosion

- Paint and Coatings

- Grease and Oil Layers

- Oxide Films

- Dust and Particulate Contaminants

- Weld Residues or Scale

- Soot and Carbon Deposits

What Laser Power Options Are Available For Laser Cleaning Machines?

- Continuous Laser Cleaning Machines: Continuous wave lasers emit a steady beam, making them ideal for fast, deep cleaning over large areas. They are well-suited for industrial-scale applications and tougher surface contaminants. The available power options for continuous laser cleaning machines are:

- 1500W: Suitable for removing light-to-moderate rust, oil, paint, and oxide layers from metal surfaces.

- 2000W: Provides a balance between cleaning power and speed, ideal for general industrial use.

- 3000W: Better for thicker coatings and larger surface areas, often used in shipbuilding and steel fabrication.

- 6000W: A high-power solution for removing thick rust, heavy coatings, and multilayer paint from large steel structures and machinery.

- Pulsed Laser Cleaning Machines: Pulsed lasers emit short bursts of energy, making them ideal for precision cleaning where substrate damage must be avoided. They are used in electronics, restoration, and delicate material treatment. The available power options for pulsed laser cleaning machines are:

- 100W: Ideal for micro-cleaning tasks such as mold maintenance, thin oxide removal, or precision tools.

- 200W: Suitable for cleaning small parts and light rust or grease from intricate metal components.

- 300W: A mid-range option for precision cleaning of mechanical parts or small molds.

- 500W: Balances cleaning efficiency with surface protection—good for industrial components with light coatings.

- 1000W: Stronger pulse energy allows for moderate rust or paint removal on sensitive materials.

- 2000W: Highest pulsed laser power for thicker contaminants or applications where controlled cleaning is essential but aggressive performance is needed.

What Are the Disadvantages of Laser Cleaning Machines?

- High Initial Investment: Laser cleaning machines—especially high-power continuous and pulsed models—can be expensive, with prices ranging from $10,000 to over $100,000 depending on power, type, and configuration.

- Impact: The cost may be prohibitive for small workshops or occasional users.

- Note: Long-term savings on consumables and labor may offset the initial expense in high-use settings.

- Limited Material Compatibility: While highly effective on metals and hard surfaces, laser cleaning is not suitable for all materials.

- Issue: Soft plastics, thin coatings, painted composites, or organic materials may melt, burn, or emit toxic fumes.

- Note: Material testing is recommended before application on non-metallic or heat-sensitive surfaces.

- Slower Speed for Heavy Coatings: Laser cleaning excels at removing thin contaminants like rust, oil, and oxides, but it can be slower than abrasive or chemical methods for thick paint layers, heavy corrosion, or tar-like residues.

- Impact: May increase cleaning time in large-scale industrial applications.

- Laser Safety Risks: Laser cleaning systems—especially those using Class 4 lasers—pose significant safety hazards.

- Risks: Eye injury, skin burns, and fire hazards from direct or reflected beams.

- Requirement: Strict adherence to laser safety protocols, including protective eyewear, interlocks, barriers, and training.

- Technical Complexity and Setup: Proper operation requires precise adjustment of power, frequency, scan speed, and focus to avoid substrate damage and optimize performance.

- Impact: Not plug-and-play; operators must be trained to avoid inefficiency or surface etching.

- Note: Advanced systems may offer preset modes, but manual fine-tuning is often needed.

- Ineffective for Internal or Hidden Areas: Laser beams work in a line-of-sight manner, making it difficult to clean inside tubes, grooves, or deep cavities.

- Workaround: May require manual repositioning or be combined with other cleaning methods.

- Infrastructure Requirements: High-power machines often require stable high-voltage power, industrial cooling systems, and dust control ventilation.

- Impact: Not ideal for mobile, remote, or outdoor environments without proper infrastructure.

- Note: Air-cooled and battery-powered portable models are available, but with limited power.

Why Are Laser Cleaning Machines So Expensive?

- Laser Source Technology: Laser cleaning machines rely on advanced fiber or pulsed lasers, which are the most expensive components. These lasers are engineered for long service life (up to 100,000 hours), high beam quality, and energy efficiency, but their development and precision manufacturing come at a high cost. Continuous lasers (1500W–6000W) are ideal for fast, heavy-duty cleaning. Pulsed lasers (100W–2000W) are more precise and more costly per watt due to their sophisticated control systems.

- Precision Optics and Scanning Systems: These machines use high-end optical systems—including focusing lenses, galvanometer scanners, and beam delivery modules—to ensure the laser hits the target material precisely and consistently. Such optics require high-grade materials, careful alignment, and protective coatings, all of which increase manufacturing cost.

- Cooling and Power Infrastructure: High-power laser systems generate heat and need advanced cooling systems, such as water chillers or high-efficiency air cooling units. In addition, stable high-voltage power supply systems and safety grounding are necessary to support continuous operation.

- Built-in Safety Mechanisms: Since laser cleaning involves Class 4 lasers, machines must incorporate emergency stops, interlocks, key switches, and shielding systems to prevent eye or skin injury. Meeting international safety certifications (like CE, FDA, or ISO) increases compliance and production costs.

- Control Systems and Software: Laser cleaning machines use CNC-level control panels, programmable interfaces, and material-specific parameter libraries, all of which require software engineering, testing, and updates.

- Durable, Industrial-Grade Design: These machines are built to function reliably in harsh environments, including factories, shipyards, and power plants. Enclosures, cables, and frames must be dust-proof, vibration-resistant, and heat-stable, using top-grade materials.

- R&D and Market Scale: Laser cleaning is a relatively new and specialized field, with limited global production volumes compared to conventional cleaning methods. The cost of research, development, testing, and after-sales service is built into the final price.

How to Choose Laser Cleaning Machines?

- Cleaning Requirements: Laser cleaning machines come in different configurations and power levels tailored to the kind of contaminants you intend to remove.

- Light Rust and Oil: Pulsed lasers with 100W to 300W power can clean thin layers of rust, oil, and oxide films from metal surfaces without damaging the base material.

- Medium Rust and Paint: Pulsed lasers with 500W to 1000W or continuous lasers at 1500W–2000W are better suited for removing paint, scale, and surface corrosion from automotive parts, tools, or molds.

- Heavy Coatings and Thick Corrosion: For industrial-scale tasks like removing marine coatings, thick rust layers, or oxide scale from structural steel, continuous wave lasers with 3000W or 6000W power are ideal.

- Type of Laser: The choice between continuous and pulsed lasers depends on surface sensitivity and cleaning intensity.

- Continuous Lasers: Deliver a steady beam, best for fast cleaning on durable materials like carbon steel and aluminum. Ideal for heavy-duty applications.

- Pulsed Lasers: Deliver bursts of energy, suitable for precision cleaning on sensitive surfaces such as stainless steel, copper, electronics, or heritage artifacts.

- Material Compatibility: Laser cleaning is most effective on metals and hard surfaces.

- Ferrous and Non-Ferrous Metals: Suitable for both continuous and pulsed cleaning.

- Plastics and Painted Composites: May require lower-powered pulsed lasers to avoid melting or burning.

- Stones, Ceramics, and Delicate Finishes: Pulsed lasers with finely tuned parameters help prevent surface damage.

- Power Options: The available power ranges affect the cleaning speed and depth.

- Pulsed Lasers: 100W, 200W, 300W, 500W, 1000W, 2000W

- Continuous Lasers: 1500W, 2000W, 3000W, 6000W

- Higher power enables faster cleaning but may not be suitable for heat-sensitive surfaces.

- Work Environment and Portability:

- Factory Setting: Stationary or large-format machines with water cooling are suitable.

- On-Site Maintenance: Air-cooled, portable, or backpack laser cleaning machines allow for greater mobility.

- Indoor Use: Ensure the machine supports fume extraction to remove vaporized contaminants safely.

- Safety and Control Features:

- Look for features like emergency stop buttons, interlocks, laser-safe enclosures, touchscreen controls, and customizable parameters.

- Laser safety goggles rated for the laser’s wavelength are essential for operator protection.

What Is the Difference Between Continuous Laser Cleaning and Pulse Laser Cleaning?

- Laser Type: Continuous wave lasers are best suited for heavy-duty applications such as removing thick rust, paint, or industrial coatings. Pulsed lasers, on the other hand, are ideal for fine cleaning tasks where precision and minimal thermal impact are critical, perfect for sensitive surfaces.

- Power Output: High-power machines (e.g., 2000W-6000W) deliver faster cleaning and can handle demanding jobs, but come at a higher cost. Lower-power systems (e.g., 100W–500W) are more affordable and suitable for delicate or lightweight cleaning tasks.

- Material Compatibility: The type of material being cleaned significantly impacts machine selection. Metals can generally withstand higher power, while plastics, rubbers, and coated surfaces may require pulsed or lower-power lasers to prevent damage.

- Cleaning Area Size: For large-scale surfaces, a high-power continuous laser improves efficiency. For smaller, intricate components, pulsed lasers with fine beam control are more effective.

- Mobility and Installation: Consider whether a portable or stationary unit is more appropriate. Portable models are convenient for on-site or field operations, while stationary systems are better for high-throughput industrial environments.

- Safety and Regulations: Make sure the machine complies with relevant safety standards. Essential features include protective enclosures, emergency stop functions, interlock systems, and proper operator training and PPE (personal protective equipment).

- Cost and Return on Investment: Evaluate your budget against the machine’s capabilities. Often, a well-balanced mid-range system can deliver the most value by aligning performance with your specific cleaning goals.

Do Laser Cleaning Machines Require Ventilation Systems When in Use?

- Fume and Dust Generation

- Laser cleaning machines work by vaporizing contaminants such as rust, paint, oil, oxides, and coatings from a material’s surface. This process produces smoke, fine particulate matter, and chemical gases, which can pose health risks if inhaled.

- On metals with surface coatings, lasers can release hazardous fumes such as lead vapor, chromium compounds, or VOCs (volatile organic compounds).

- On oily or greased components, the vaporized material may produce smoke with hydrocarbons or aerosols.

- Health and Safety Considerations

- Operators exposed to airborne laser-cleaning byproducts may experience eye, skin, or respiratory irritation. Extended exposure without adequate ventilation can violate workplace safety regulations, especially in enclosed or poorly ventilated spaces.

- Laser cleaning machines are typically Class 4 devices, requiring safety protocols including ventilation and fume extraction to meet OSHA and CE safety standards.

- Ventilation Systems Required

- Fume Extraction Units: Portable or built-in extractors with HEPA and activated carbon filters to trap particulates and absorb gases

- Local Exhaust Ventilation (LEV): A nozzle positioned near the laser beam captures smoke and dust at the source

- Ducted Ventilation Systems: For industrial installations with higher cleaning frequency or volume

- Ambient Air Handling Units: In combination with LEV for general workshop air quality

What Personal Protective Equipment Is Required When Using Laser Cleaning Machines?

- Laser Safety Glasses

- Laser beams can cause severe eye injuries, even from scattered or reflected light.

- Operators must wear laser safety goggles rated for the specific laser wavelength (usually 1064 nm for fiber lasers).

- The glasses must have an appropriate optical density (OD) to block the beam and comply with standards such as EN 207 or ANSI Z136.1.

- Protective Clothing

- Operators should wear flame-resistant, non-reflective clothing to protect their skin from accidental exposure to the laser beam and flying particles.

- Long-sleeved garments and pants are recommended. Synthetic or shiny materials should be avoided as they may reflect laser energy.

- Gloves

- Gloves may be necessary when handling hot or contaminated materials.

- Heat-resistant or cut-resistant gloves are recommended, especially when cleaning metal components. However, gloves must be non-reflective and laser-safe.

- Respiratory Protection

- Laser cleaning produces smoke, dust, and vaporized materials, especially when removing coatings, oils, or rust.

- Use a fume extraction system with HEPA and activated carbon filters to remove airborne contaminants. In confined spaces or poorly ventilated areas, operators should wear respirators (e.g., N95 or P100 masks).

- Foot Protection

- If working in an industrial setting, wear steel-toe safety boots to prevent injuries from dropped tools or heavy workpieces.

- Boots should have non-reflective surfaces and anti-slip soles.

- Hearing Protection (if applicable)

- Some laser cleaning systems, especially high-power continuous types, may generate high noise levels.

- Use ear protection such as earplugs or earmuffs in noisy environments.