Manufacturing Capacity For Faster Laser

At Faster Laser, we take pride in our state-of-the-art manufacturing capabilities, ensuring that we deliver high-quality laser cutting, cleaning, welding, and marking machines to meet the evolving demands of global industries. Our advanced production facilities, cutting-edge technology, and rigorous quality control standards enable us to manufacture precision-engineered laser solutions that set new benchmarks for performance, reliability, and efficiency.

Advanced Production Facilities

Our manufacturing plants are equipped with modern automation and intelligent production systems, enabling high-volume, high-precision production while maintaining the highest quality standards.

- Manufacturing Space: Large-scale industrial facilities spanning thousands of square meters, with dedicated production lines for different laser systems.

- Production Equipment: Advanced CNC machining centers, robotic assembly lines, and laser calibration tools ensure precision manufacturing.

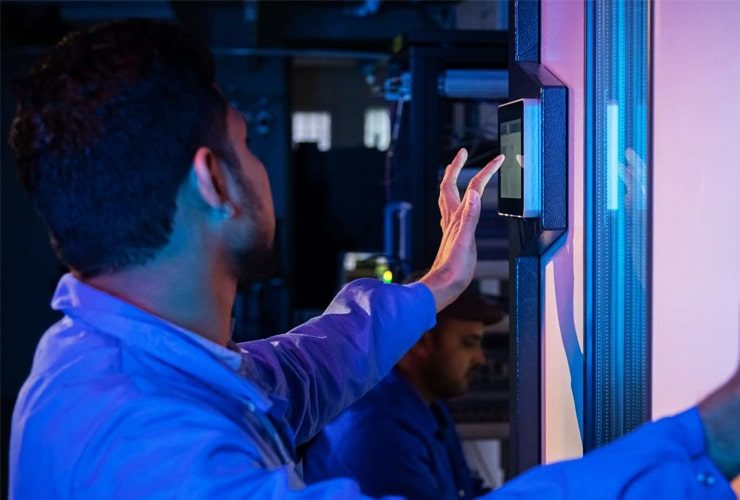

- Smart Manufacturing Integration: Implementation of Industry 4.0 technologies, including automated production monitoring, AI-driven diagnostics, and digital twin simulations for real-time quality control and production optimization.

High-Precision Engineering & Assembly

We follow a rigorous precision engineering process to ensure that each Faster Laser machine is manufactured with exceptional accuracy, reliability, and longevity.

- Component Fabrication: High-precision 5-axis CNC machining, laser cutting, and metal processing are used to manufacture critical components.

- Robotic Assembly: Automated robotic systems ensure consistent assembly and alignment for all machines.

- Optical Calibration: Ultra-precise laser calibration technology guarantees optimal beam quality and performance.

- Modular Design: Machines are designed with interchangeable components, enabling easy upgrades, maintenance, and customization.

Strict Quality Control & Testing Procedures

We maintain a robust supply chain system, ensuring that our laser machines are delivered on time and in perfect condition to customers worldwide.

Multi-Stage Quality Control Process

- Reliable Sourcing: We partner with global suppliers for high-quality laser components, including fiber laser sources, optics, and precision electronic systems.

- Efficient Warehousing & Distribution: Our global logistics network allows us to ship machines to over 100+ countries with fast turnaround times.

- After-Sales Support & Spare Parts Availability: We maintain a large inventory of spare parts and accessories, ensuring quick replacements and minimal downtime.

Global Supply Chain & Logistics Efficiency

We maintain a robust supply chain system, ensuring that our laser machines are delivered on time and in perfect condition to customers worldwide.

Supply Chain Strengths

- Reliable Sourcing: We partner with global suppliers for high-quality laser components, including fiber laser sources, optics, and precision electronic systems.

- Efficient Warehousing & Distribution: Our global logistics network allows us to ship machines to over 100+ countries with fast turnaround times.

- After-Sales Support & Spare Parts Availability: We maintain a large inventory of spare parts and accessories, ensuring quick replacements and minimal downtime.

Commitment to Sustainability in Manufacturing

Faster Laser is dedicated to sustainable and environmentally responsible manufacturing through the use of eco-friendly production processes and energy-efficient laser technology.

Sustainable Manufacturing Practices

- Low-Energy Production Processes: Reducing carbon emissions by implementing energy-efficient production techniques.

- Material Waste Reduction: Optimizing raw material usage and recycling scrap materials.

- Eco-Friendly Laser Solutions: Developing high-efficiency fiber lasers that consume less power and provide a greener alternative to traditional manufacturing methods.

Green Packaging & Logistics

- Recyclable & eco-friendly packaging materials to reduce waste.

- Optimized shipping routes to minimize transportation emissions.

Research & Development (R&D) Integration

Our R&D-driven manufacturing approach enables Faster Laser to stay ahead of the competition, continuously improving our production processes and laser technology.

Key Innovations in Manufacturing

- Integration of AI-powered automation for precision control.

- Development of next-generation fiber laser systems with enhanced efficiency.

- Implementation of IoT-enabled smart laser machines for remote monitoring and predictive maintenance.

Future Expansion Plans

- Expansion of our manufacturing facilities to increase annual production capacity.

- Implementation of fully automated production lines for higher efficiency.

- Research into new laser applications and materials processing techniques.

Get Customized Laser Solutions

At Faster Laser, we pride ourselves on our robust manufacturing capabilities that enable us to deliver high-quality laser solutions tailored to your business needs. Our state-of-the-art facilities are equipped with advanced machinery and technologies, allowing us to maintain stringent quality control and efficient production processes. By leveraging our extensive manufacturing capacity, we ensure timely delivery and scalability to support your growth. Contact us today to learn how our manufacturing excellence can empower your operations.

* We value your privacy. Faster Laser is committed to protecting your personal information. Any details you provide when submitting the form will be kept strictly confidential and used only to assist with your inquiry. We do not share, sell, or disclose your information to third parties. Your data is securely stored and handled by our privacy policy.